- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 13:56

Back to list

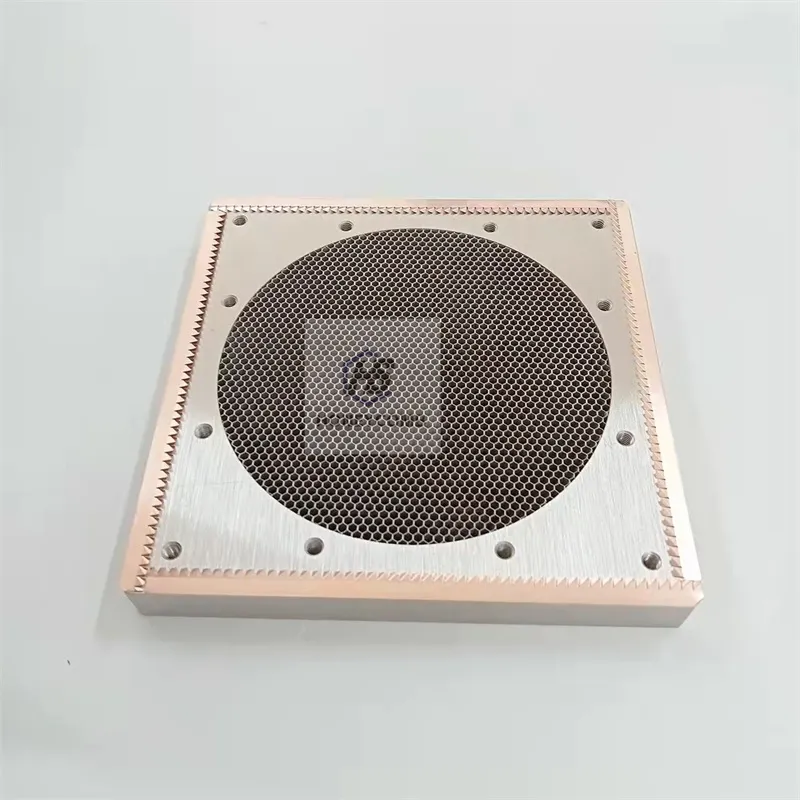

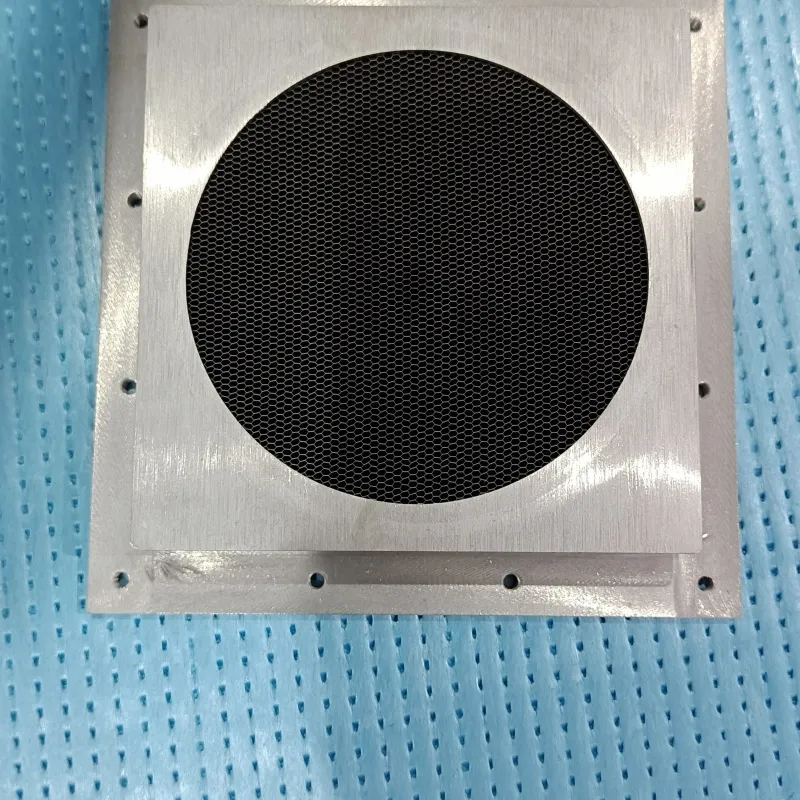

air flow straightener

Metal honeycomb core, an innovative product used prominently in various industries, offers a unique blend of strength, flexibility, and efficiency. Its applications range from aerospace engineering to architecture, epitomizing its versatility and indispensability in modern technology.

Titanium honeycomb cores represent the pinnacle of high-performance applications, predominantly used in aerospace and defense sectors. With exceptional strength-to-weight ratios and resistance to extreme temperatures, titanium cores are integral to parts that endure substantial thermal and physical stress, such as spacecraft and military-grade vehicles. The incorporation of titanium is synonymous with performance and reliability, benchmarks imperative for missions where failure is not an option. In developing these advanced materials, expertise and experience converge, ensuring each honeycomb core is perfectly tailored for its intended use. Professionals in engineering and manufacturing disciplines continuously evolve their techniques, guided by rigorous testing protocols and stringent industry standards. This constant innovation nurtures trust and credibility, confirming that only the highest quality products reach the market. For businesses working with metal honeycomb cores, understanding these unique attributes is vital. Selecting the appropriate material not only optimizes performance but also economizes resources, ensuring sustainability and adherence to environmental regulations. Collaboration with trusted suppliers enhances this understanding, promoting informed decisions that align with project specifications and long-term strategic objectives. Metal honeycomb cores epitomize the pursuit of excellence in engineering. Their embodiment of strength, resilience, and adaptability positions them as pivotal components within several industries. With ongoing research and development, these cores will undoubtedly continue to evolve, driving innovation and setting standards across sectors. Their integration reflects a commitment to quality and sustainability, solidifying their role in shaping the future of design and technology.

Titanium honeycomb cores represent the pinnacle of high-performance applications, predominantly used in aerospace and defense sectors. With exceptional strength-to-weight ratios and resistance to extreme temperatures, titanium cores are integral to parts that endure substantial thermal and physical stress, such as spacecraft and military-grade vehicles. The incorporation of titanium is synonymous with performance and reliability, benchmarks imperative for missions where failure is not an option. In developing these advanced materials, expertise and experience converge, ensuring each honeycomb core is perfectly tailored for its intended use. Professionals in engineering and manufacturing disciplines continuously evolve their techniques, guided by rigorous testing protocols and stringent industry standards. This constant innovation nurtures trust and credibility, confirming that only the highest quality products reach the market. For businesses working with metal honeycomb cores, understanding these unique attributes is vital. Selecting the appropriate material not only optimizes performance but also economizes resources, ensuring sustainability and adherence to environmental regulations. Collaboration with trusted suppliers enhances this understanding, promoting informed decisions that align with project specifications and long-term strategic objectives. Metal honeycomb cores epitomize the pursuit of excellence in engineering. Their embodiment of strength, resilience, and adaptability positions them as pivotal components within several industries. With ongoing research and development, these cores will undoubtedly continue to evolve, driving innovation and setting standards across sectors. Their integration reflects a commitment to quality and sustainability, solidifying their role in shaping the future of design and technology.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025