- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 14, 2025 16:22

Back to list

honeycomb core steel door

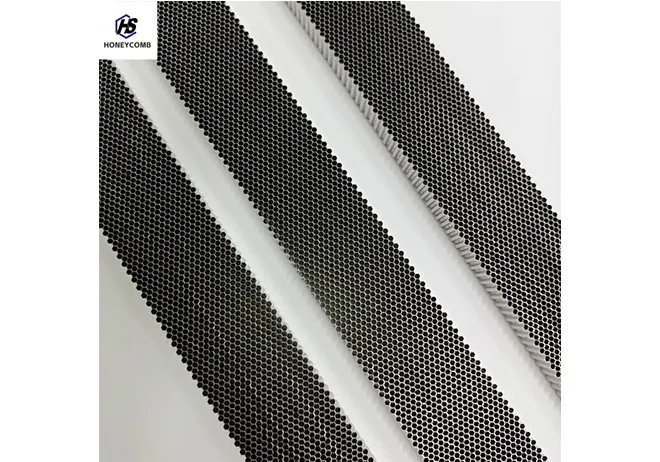

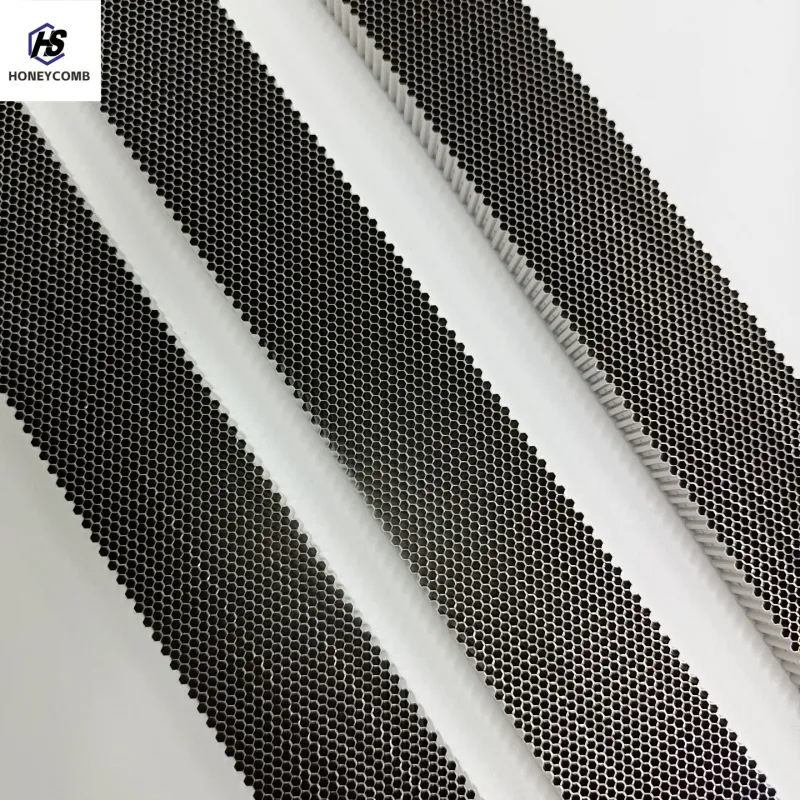

The EMI honeycomb filter has emerged as a vital component in electronic device manufacturing, offering substantial benefits in the ever-evolving landscape of engineering and technology. These filters are specifically designed to mitigate electromagnetic interference (EMI), which can adversely affect the performance and reliability of electronic devices. This article will delve into the real-world applications, technical expertise, authoritative insights, and trustworthy data surrounding the use of EMI honeycomb filters, making it an invaluable resource for industry professionals and enthusiasts alike.

Authoritativeness is further underscored by the endorsements and certifications from recognized industry bodies. Leading manufacturers of EMI honeycomb filters often hold certifications from authoritative entities such as the International Electrotechnical Commission (IEC) or the Institute of Electrical and Electronics Engineers (IEEE). Such endorsements are a testament to the product’s efficacy and reliability, offering additional assurance to engineers and end-users regarding the filter’s performance capabilities. Trustworthiness, a cornerstone of any technological product, is reinforced through rigorous testing and real-world performance feedback. Customers often seek reassurance that EMI honeycomb filters will perform as advertised under diverse operating conditions. Documented success stories across various industries, from ensuring the seamless operation of avionics systems to stabilizing sensitive medical equipment, provide tangible proof of these filters' reliability and effectiveness. Trust is earned through transparency and consistent results, which are critical components of maintaining buyer confidence in such a specialized field. In conclusion, the EMI honeycomb filter represents a sophisticated fusion of design ingenuity, professional expertise, and authoritative validation. By offering a robust solution to manage electromagnetic interference, these filters play a pivotal role in ensuring the reliability and efficiency of electronic devices across multiple sectors. Their design and application demand a deep understanding of electromagnetic theory, material science, and engineering best practices, all of which converge to set leading examples of trustworthiness and innovation. With a growing need for effective EMI solutions in an increasingly electronic-dependent world, the EMI honeycomb filter stands out as a reliable choice for engineers and manufacturers committed to excellence in their technological pursuits.

Authoritativeness is further underscored by the endorsements and certifications from recognized industry bodies. Leading manufacturers of EMI honeycomb filters often hold certifications from authoritative entities such as the International Electrotechnical Commission (IEC) or the Institute of Electrical and Electronics Engineers (IEEE). Such endorsements are a testament to the product’s efficacy and reliability, offering additional assurance to engineers and end-users regarding the filter’s performance capabilities. Trustworthiness, a cornerstone of any technological product, is reinforced through rigorous testing and real-world performance feedback. Customers often seek reassurance that EMI honeycomb filters will perform as advertised under diverse operating conditions. Documented success stories across various industries, from ensuring the seamless operation of avionics systems to stabilizing sensitive medical equipment, provide tangible proof of these filters' reliability and effectiveness. Trust is earned through transparency and consistent results, which are critical components of maintaining buyer confidence in such a specialized field. In conclusion, the EMI honeycomb filter represents a sophisticated fusion of design ingenuity, professional expertise, and authoritative validation. By offering a robust solution to manage electromagnetic interference, these filters play a pivotal role in ensuring the reliability and efficiency of electronic devices across multiple sectors. Their design and application demand a deep understanding of electromagnetic theory, material science, and engineering best practices, all of which converge to set leading examples of trustworthiness and innovation. With a growing need for effective EMI solutions in an increasingly electronic-dependent world, the EMI honeycomb filter stands out as a reliable choice for engineers and manufacturers committed to excellence in their technological pursuits.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025