- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 03:06

Back to list

металлические соты

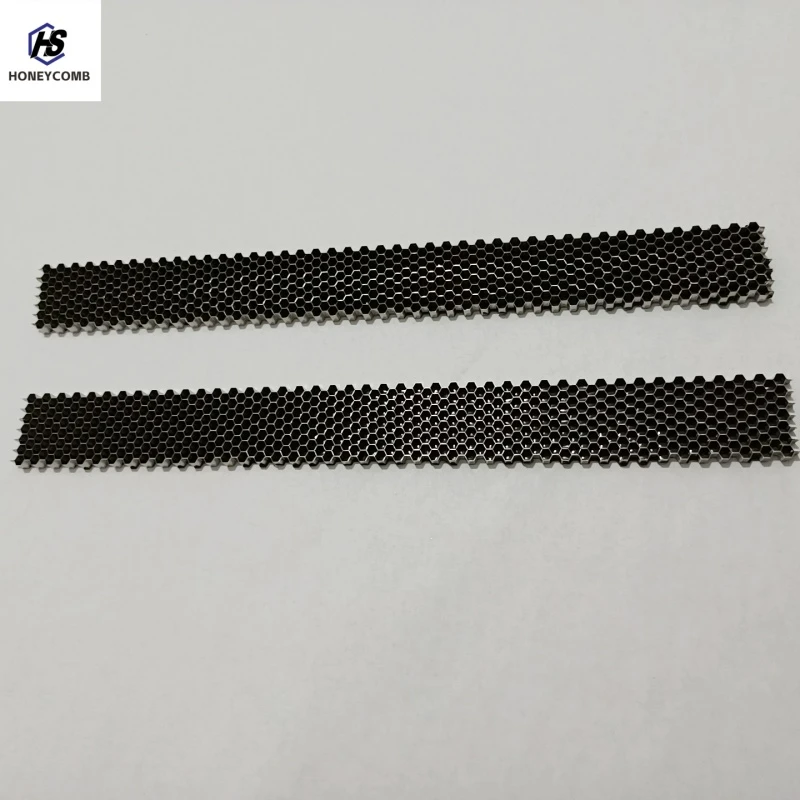

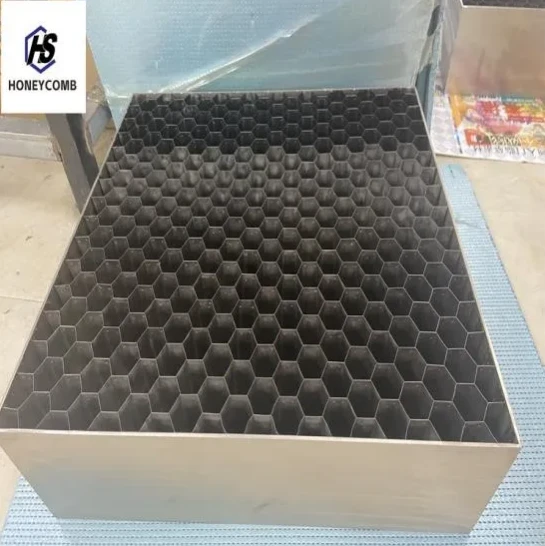

Metallic honeycombs, a remarkable innovation in materials engineering, are gaining increasing attention for their versatile applications and outstanding properties. These structures, inspired by the natural geometry of beehives, deliver unparalleled strength-to-weight ratios, thermal insulation, and acoustic damping capabilities, making them indispensable in various industrial sectors.

The expertise involved in producing metallic honeycombs is derived from advanced manufacturing techniques. These typically involve the precision expansion and brazing of metal foils to create uniform cell structures. Aluminum, stainless steel, and titanium are commonly used metals, each chosen based on specific properties required for different applications. The manufacturing process not only requires expert-level skills but also a deep understanding of material science to ensure that the desired mechanical and physical properties are achieved. Trustworthiness in the use of metallic honeycombs is reinforced by rigorous testing and compliance with industry standards. Manufacturers are committed to maintaining top quality, ensuring that these materials meet strict safety guidelines and performance expectations. Certifications from recognized bodies further enhance credibility, reassuring customers of the product’s reliability and durability. Users can trust that incorporating metallic honeycombs into their projects will lead to enhanced performance and long-term benefits. For those considering the integration of metallic honeycombs into their projects, collaboration with experienced suppliers and manufacturers is essential. This partnership ensures access to expert guidance, helping determine the most suitable material specifications and configurations for each application. Whether for increasing structural integrity, reducing weight, or achieving better energy efficiency, harnessing the full potential of metallic honeycombs requires expert input and innovative thinking. In summary, metallic honeycombs present a revolutionary advancement in material science with multifaceted applications across various industries. Their unparalleled strength-to-weight ratio, thermal and acoustic benefits, coupled with rigorous testing and authoritative expertise, establish them as a go-to solution for modern engineering challenges. By adopting these structures, industries not only meet their immediate technical demands but also contribute to broader sustainability goals, safeguarding the environment while pushing the boundaries of innovation.

The expertise involved in producing metallic honeycombs is derived from advanced manufacturing techniques. These typically involve the precision expansion and brazing of metal foils to create uniform cell structures. Aluminum, stainless steel, and titanium are commonly used metals, each chosen based on specific properties required for different applications. The manufacturing process not only requires expert-level skills but also a deep understanding of material science to ensure that the desired mechanical and physical properties are achieved. Trustworthiness in the use of metallic honeycombs is reinforced by rigorous testing and compliance with industry standards. Manufacturers are committed to maintaining top quality, ensuring that these materials meet strict safety guidelines and performance expectations. Certifications from recognized bodies further enhance credibility, reassuring customers of the product’s reliability and durability. Users can trust that incorporating metallic honeycombs into their projects will lead to enhanced performance and long-term benefits. For those considering the integration of metallic honeycombs into their projects, collaboration with experienced suppliers and manufacturers is essential. This partnership ensures access to expert guidance, helping determine the most suitable material specifications and configurations for each application. Whether for increasing structural integrity, reducing weight, or achieving better energy efficiency, harnessing the full potential of metallic honeycombs requires expert input and innovative thinking. In summary, metallic honeycombs present a revolutionary advancement in material science with multifaceted applications across various industries. Their unparalleled strength-to-weight ratio, thermal and acoustic benefits, coupled with rigorous testing and authoritative expertise, establish them as a go-to solution for modern engineering challenges. By adopting these structures, industries not only meet their immediate technical demands but also contribute to broader sustainability goals, safeguarding the environment while pushing the boundaries of innovation.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025