- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 05:55

Back to list

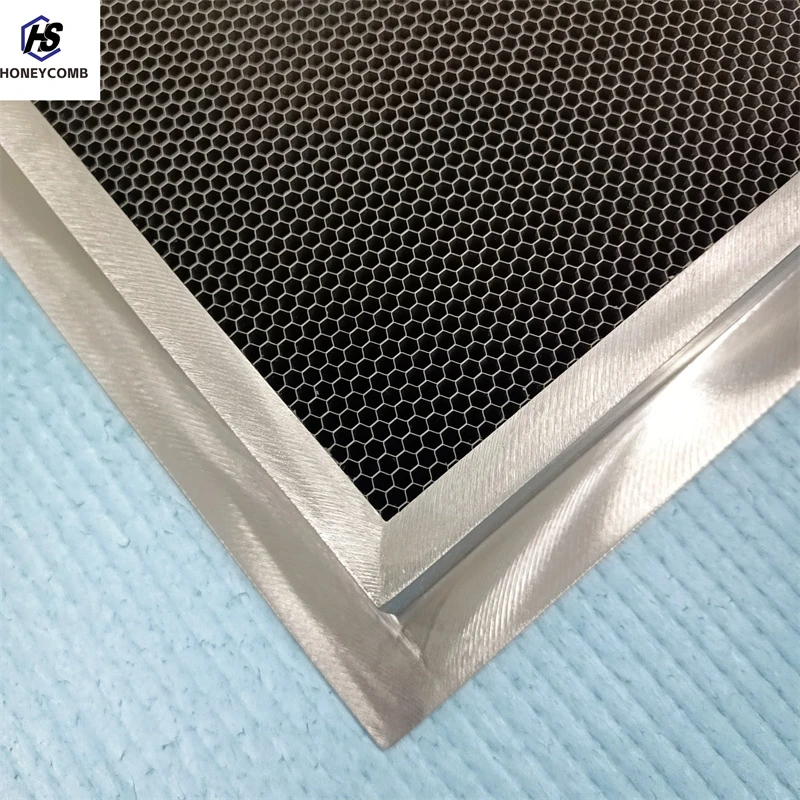

air flow straightener

Electromagnetic interference (EMI) shielding filters are critical components in ensuring the smooth functioning of electronic devices in an increasingly wireless world. These filters are uniquely designed to block unwanted electromagnetic waves, which can otherwise lead to disruptive interference with electronic components, resulting in malfunctions or reduced performance.

One should consider the shielding effectiveness testing methods employed by manufacturers, such as the MIL-STD-285 or IEEE 299, which provide a detailed measure of a filter's performance. These methods test the filter under various conditions and frequencies, ensuring comprehensive evaluations. Companies with proprietary testing technologies may offer an edge by promising higher precision and adaptability in real-world scenarios. Apart from performance and compliance, the environmental impact and sustainability of EMI shielding solutions are garnering attention. With a shift towards eco-friendly materials, producers are exploring recyclable and biodegradable options that do not compromise the filter's performance, catering to the environmentally conscious market segments. Trustworthiness in this field extends beyond product claims. Transparent communication regarding the capabilities and limitations of EMI shielding filters is key to building credibility. Manufacturers capable of providing tailored consultations, thereby aligning their technical offerings with customer requirements, can significantly enhance customer satisfaction and trust. To conclude, the realm of electromagnetic interference shielding is marked by continuous innovation and a strong orientation towards addressing modern technological challenges. By focusing on expertise, authoritative testing, and sustainable practices, manufacturers can distinguish themselves while offering reliable and efficient EMI shielding filters that meet the evolving needs of electronic device applications.

One should consider the shielding effectiveness testing methods employed by manufacturers, such as the MIL-STD-285 or IEEE 299, which provide a detailed measure of a filter's performance. These methods test the filter under various conditions and frequencies, ensuring comprehensive evaluations. Companies with proprietary testing technologies may offer an edge by promising higher precision and adaptability in real-world scenarios. Apart from performance and compliance, the environmental impact and sustainability of EMI shielding solutions are garnering attention. With a shift towards eco-friendly materials, producers are exploring recyclable and biodegradable options that do not compromise the filter's performance, catering to the environmentally conscious market segments. Trustworthiness in this field extends beyond product claims. Transparent communication regarding the capabilities and limitations of EMI shielding filters is key to building credibility. Manufacturers capable of providing tailored consultations, thereby aligning their technical offerings with customer requirements, can significantly enhance customer satisfaction and trust. To conclude, the realm of electromagnetic interference shielding is marked by continuous innovation and a strong orientation towards addressing modern technological challenges. By focusing on expertise, authoritative testing, and sustainable practices, manufacturers can distinguish themselves while offering reliable and efficient EMI shielding filters that meet the evolving needs of electronic device applications.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025