- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 08:23

Back to list

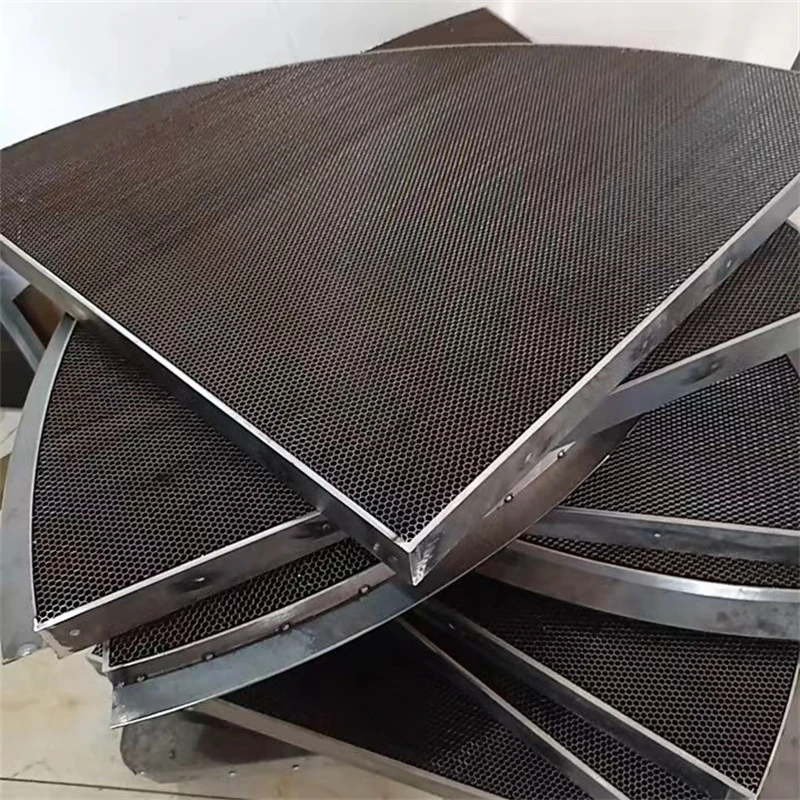

stainless steel honeycomb stand

Copper honeycombs have distinctively captured the intrigue of industries ranging from architecture to energy. Renowned for their exceptional conductivity, durability, and aesthetic allure, these versatile structures have found utility in an expanding array of applications, providing both practical and innovative solutions to modern technological demands.

Sustainability is another compelling reason why copper honeycombs are proving indispensable. With the growing global emphasis on sustainable materials, copper stands out due to its recyclability. Copper honeycombs can be reused and repurposed without losing their distinctive properties, promoting a circular economy and reducing environmental impacts. This intrinsic recyclability highlights not only the versatility but also the environmental stewardship embodied by copper honeycomb structures. The increasing adoption of copper honeycombs is underpinned by trust in their long-term reliability and performance. Rigorous testing across various conditions has consistently demonstrated their ability to withstand significant mechanical stress, corrosion, and environmental variations. This steadfast performance allows them to be confidently integrated into critical applications where failure is not an option. Companies specializing in manufacturing these honeycomb structures have invested considerable resources into refining production techniques, ensuring consistent quality and performance. The expertise behind crafting these materials is a testament to a deep understanding of both the demands of modern industries and the specific engineering challenges that copper honeycombs address. In essence, copper honeycombs embody a fusion of art, science, and sustainability. Their role across multiple sectors demonstrates a unique confluence of technological advancement and environmental consciousness, positioning them as indispensable components in the quest for innovation and efficiency. These characteristics, combined with their versatile applicability and reliable performance, affirm the copper honeycomb's status not just as a product but as a critical solution to contemporary industrial needs.

Sustainability is another compelling reason why copper honeycombs are proving indispensable. With the growing global emphasis on sustainable materials, copper stands out due to its recyclability. Copper honeycombs can be reused and repurposed without losing their distinctive properties, promoting a circular economy and reducing environmental impacts. This intrinsic recyclability highlights not only the versatility but also the environmental stewardship embodied by copper honeycomb structures. The increasing adoption of copper honeycombs is underpinned by trust in their long-term reliability and performance. Rigorous testing across various conditions has consistently demonstrated their ability to withstand significant mechanical stress, corrosion, and environmental variations. This steadfast performance allows them to be confidently integrated into critical applications where failure is not an option. Companies specializing in manufacturing these honeycomb structures have invested considerable resources into refining production techniques, ensuring consistent quality and performance. The expertise behind crafting these materials is a testament to a deep understanding of both the demands of modern industries and the specific engineering challenges that copper honeycombs address. In essence, copper honeycombs embody a fusion of art, science, and sustainability. Their role across multiple sectors demonstrates a unique confluence of technological advancement and environmental consciousness, positioning them as indispensable components in the quest for innovation and efficiency. These characteristics, combined with their versatile applicability and reliable performance, affirm the copper honeycomb's status not just as a product but as a critical solution to contemporary industrial needs.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025