- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 10:33

Back to list

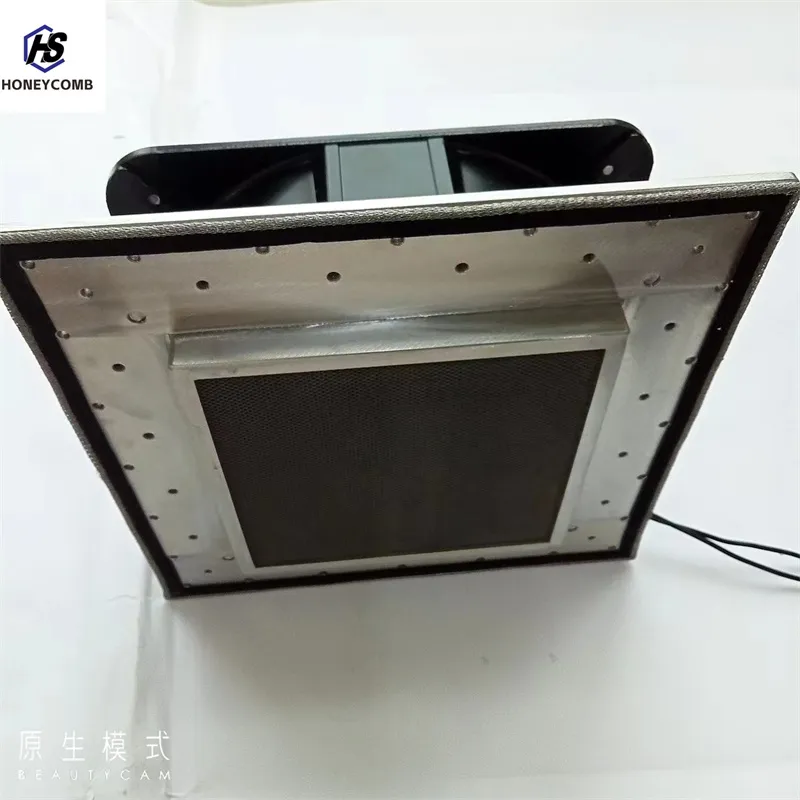

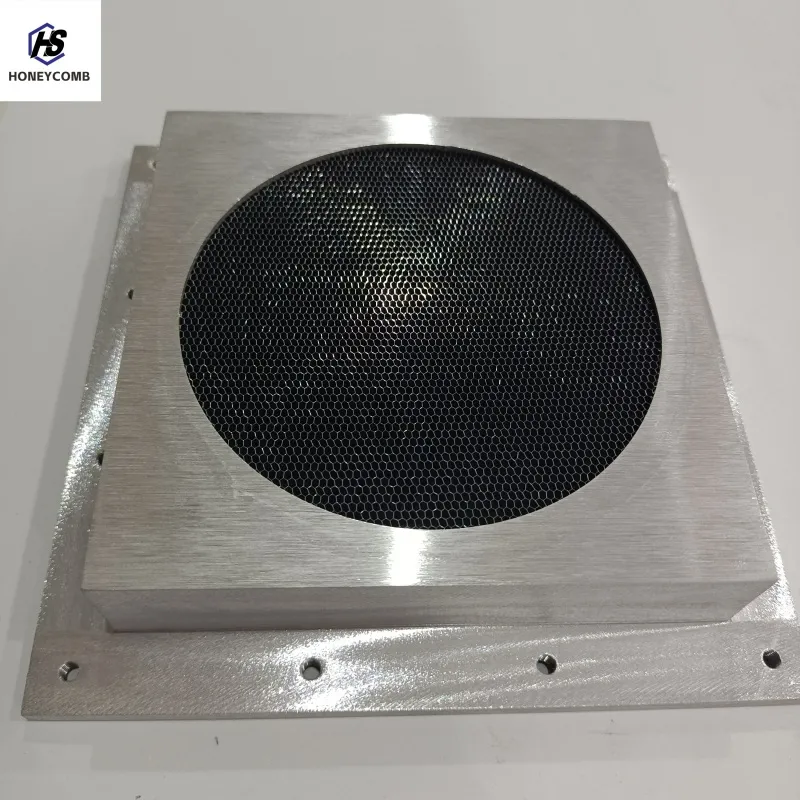

Revolutionize Your wind tunnel testing with precision Honeycomb cells ultimate aerodynamic Efficiency

The aerospace industry is experiencing a significant transformation with the advent of advanced cellular materials, also known as сотовые аэрокосмические in Russian. These materials possess a unique honeycomb structure, offering exceptional benefits in terms of weight reduction, strength, and versatility, crucial for aerospace applications. This article delves into the innovative aspects of cellular aerospace materials, exploring how they enhance aircraft performance and contribute to sustainable aviation.

Leading aerospace manufacturers have started integrating cellular materials into their design processes. For instance, companies like Boeing and Airbus are adopting these materials in their latest aircraft models. Their commitment to incorporating innovative materials underscores the authority and trustworthiness of cellular aerospace solutions. These industrial leaders recognize the potential of сотовые аэрокосмические materials to revolutionize the market, setting new standards for aircraft manufacturing. Beyond commercial aviation, these materials are increasingly being utilized in space exploration. The lightweight yet durable nature of cellular structures makes them ideal for spacecraft components, which need to withstand extreme conditions. The Mars Rover, for instance, benefits from components crafted from cellular materials, aiding its journey across the Martian landscape. For aerospace engineers and designers, the transition to cellular materials necessitates a paradigm shift. It requires embracing modern computational tools and design methodologies to fully exploit the material's capabilities. This transformative approach not only fosters innovation but also builds a credible foundation for the widespread implementation of cellular aerospace materials. In conclusion, сотовые аэрокосмические materials stand at the forefront of modern aerospace innovation, embodying a fusion of strength, efficiency, and sustainability. Their application not only propels the aerospace industry towards a greener future but also ensures enhanced performance and safety. As research continues to advance, the future of aviation will undoubtedly be shaped by these remarkable materials, marking a new era in aerospace technology.

Leading aerospace manufacturers have started integrating cellular materials into their design processes. For instance, companies like Boeing and Airbus are adopting these materials in their latest aircraft models. Their commitment to incorporating innovative materials underscores the authority and trustworthiness of cellular aerospace solutions. These industrial leaders recognize the potential of сотовые аэрокосмические materials to revolutionize the market, setting new standards for aircraft manufacturing. Beyond commercial aviation, these materials are increasingly being utilized in space exploration. The lightweight yet durable nature of cellular structures makes them ideal for spacecraft components, which need to withstand extreme conditions. The Mars Rover, for instance, benefits from components crafted from cellular materials, aiding its journey across the Martian landscape. For aerospace engineers and designers, the transition to cellular materials necessitates a paradigm shift. It requires embracing modern computational tools and design methodologies to fully exploit the material's capabilities. This transformative approach not only fosters innovation but also builds a credible foundation for the widespread implementation of cellular aerospace materials. In conclusion, сотовые аэрокосмические materials stand at the forefront of modern aerospace innovation, embodying a fusion of strength, efficiency, and sustainability. Their application not only propels the aerospace industry towards a greener future but also ensures enhanced performance and safety. As research continues to advance, the future of aviation will undoubtedly be shaped by these remarkable materials, marking a new era in aerospace technology.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025