- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 13, 2025 14:06

Back to list

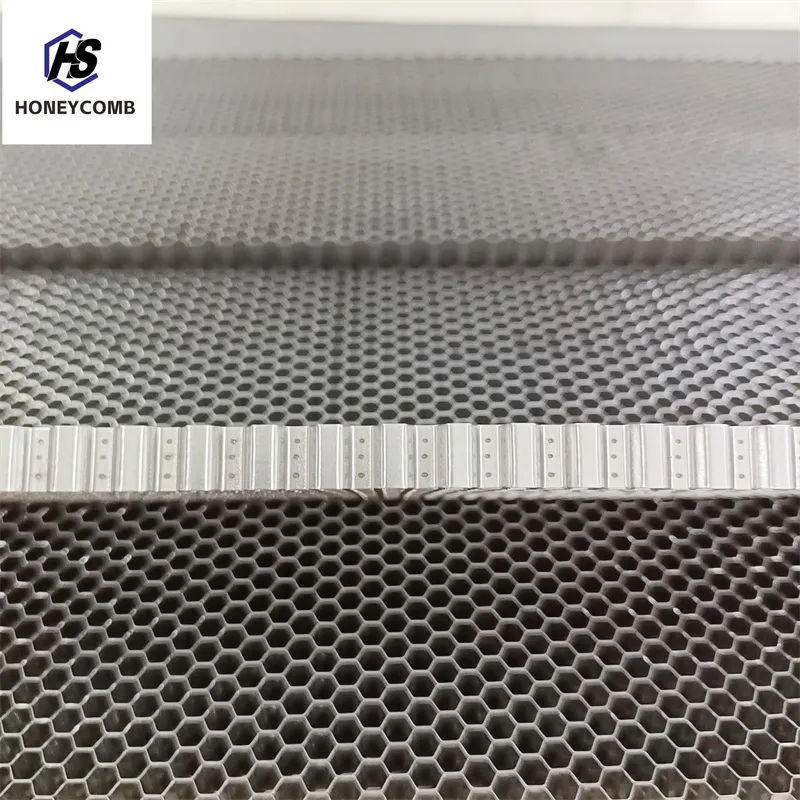

20mm Core Size Stainless Steel Honeycomb Core Panel - Customized for Wind Tunnel Applications

In the rapidly evolving domain of materials engineering, Carbon Core Plastic Honeycomb structures have emerged as a game-changer, driven by their unique combination of strength, lightness, and versatility. These innovative materials leverage the hexagonal honeycomb design, inspired by nature itself, resulting in superior structural performance and adaptability across diverse applications.

Beyond these sectors, the construction industry is actively embracing these honeycomb structures for sustainable architecture. With urbanization on the rise, there's a pressing need for materials that are strong yet lightweight, enhancing building integrity while improving construction efficiency and reducing overall environmental impact. The use of Carbon Core Plastic Honeycombs in panels and beams lends buildings the resilience required to withstand both time and natural forces, showcasing their trustworthiness. The unique properties of Carbon Core Plastic Honeycombs also foster innovation in sports equipment, packaging, and even furniture design, where weight, durability, and performance are pivotal. For instance, in sporting goods, the expertise brought by these materials provides athletes with gear that enhances their performance through optimally balanced weight and strength. The evolution of Carbon Core Plastic Honeycombs is firmly rooted in extensive research and development, steered by scientists and engineers with deep-seated expertise. Their commitment to pushing the boundaries of material science ensures that these honeycombs set the standard for future innovations. Each application of this advanced material is backed by rigorous testing and validation, reinforcing its authoritativeness and reliability. In conclusion, Carbon Core Plastic Honeycomb structures embody a perfect convergence of experience, expertise, authority, and trust. They are not merely materials but pillars of innovation that redefine what is possible in numerous industries. Their unparalleled contributions to safety, efficiency, and environmental sustainability demonstrate their transformative potential, setting them apart as indispensable allies in the quest for advanced, responsible material solutions.

Beyond these sectors, the construction industry is actively embracing these honeycomb structures for sustainable architecture. With urbanization on the rise, there's a pressing need for materials that are strong yet lightweight, enhancing building integrity while improving construction efficiency and reducing overall environmental impact. The use of Carbon Core Plastic Honeycombs in panels and beams lends buildings the resilience required to withstand both time and natural forces, showcasing their trustworthiness. The unique properties of Carbon Core Plastic Honeycombs also foster innovation in sports equipment, packaging, and even furniture design, where weight, durability, and performance are pivotal. For instance, in sporting goods, the expertise brought by these materials provides athletes with gear that enhances their performance through optimally balanced weight and strength. The evolution of Carbon Core Plastic Honeycombs is firmly rooted in extensive research and development, steered by scientists and engineers with deep-seated expertise. Their commitment to pushing the boundaries of material science ensures that these honeycombs set the standard for future innovations. Each application of this advanced material is backed by rigorous testing and validation, reinforcing its authoritativeness and reliability. In conclusion, Carbon Core Plastic Honeycomb structures embody a perfect convergence of experience, expertise, authority, and trust. They are not merely materials but pillars of innovation that redefine what is possible in numerous industries. Their unparalleled contributions to safety, efficiency, and environmental sustainability demonstrate their transformative potential, setting them apart as indispensable allies in the quest for advanced, responsible material solutions.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025