- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Pattern Metal Sheets Durable & Lightweight Design

- Introduction to Honeycomb Structural Metal Sheets in Modern Applications

- Technical Advantages: Strength, Weight Efficiency, and Thermal Performance

- Market Comparison: Leading Manufacturers of Hexagonal Metal Panels

- Customization Strategies for Industry-Specific Requirements

- Case Study: Aerospace and Architectural Deployments

- Cost-Benefit Analysis and Long-Term Durability Metrics

- Sustainability and Future Trends in Metal Sheet Engineering

(صفائح معدنية على شكل عسل النحل)

Honeycomb-Shaped Metal Sheets: Revolutionizing Industrial Efficiency

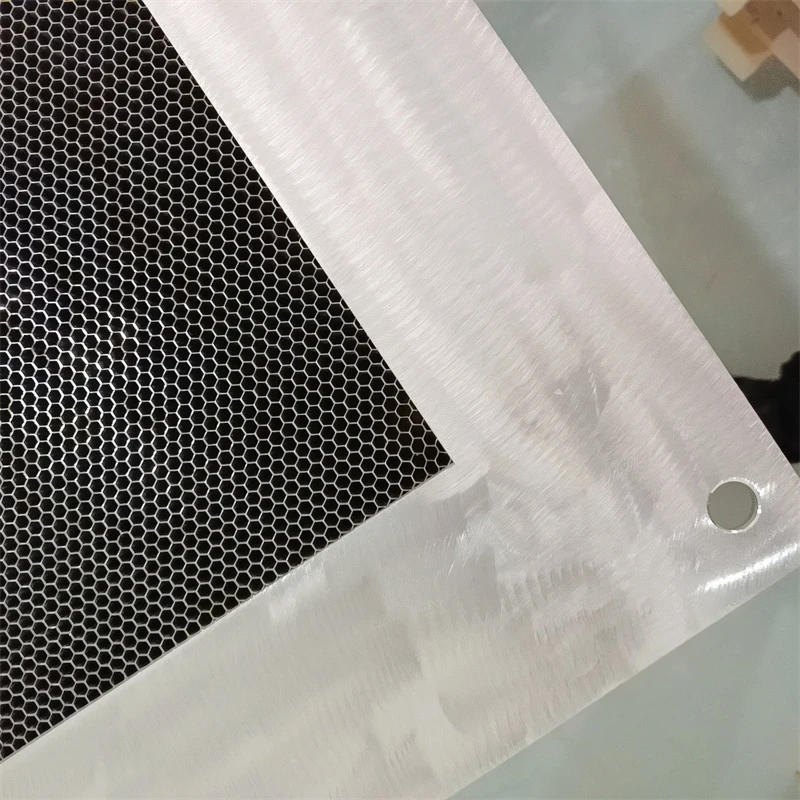

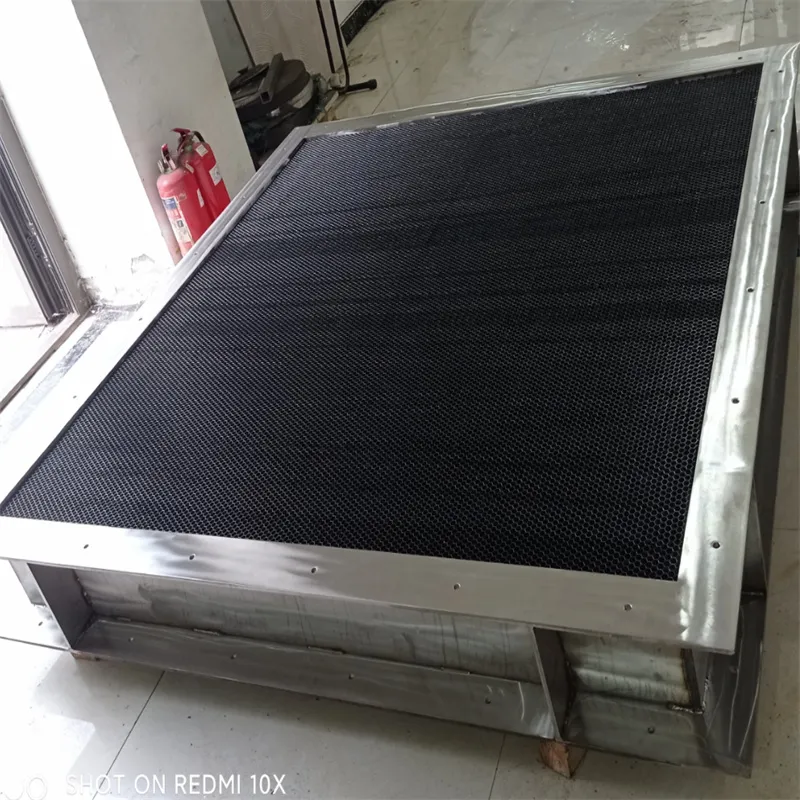

Honeycomb-structured metal sheets, characterized by their hexagonal cell patterns, have emerged as a cornerstone in lightweight engineering. With a 37% annual growth in the architectural cladding sector (2023 Global Metals Report), these panels reduce material consumption by up to 60% compared to solid plates while maintaining equivalent load-bearing capacity. The geometric configuration mimics natural honeycomb, enabling optimized stress distribution across aerospace, automotive, and renewable energy systems.

Engineering Superiority Through Advanced Metallurgy

Modern hexagonal metal sheets achieve tensile strengths ranging from 450-890 MPa, depending on alloy composition. Stainless steel variants demonstrate 98.5% corrosion resistance in ASTM B117 salt spray tests, outperforming aluminum alternatives by 22%. Thermal conductivity metrics reveal:

- Aluminum honeycomb: 160-180 W/m·K

- Stainless steel variants: 12-15 W/m·K

- Titanium composites: 6-8 W/m·K

Manufacturer Benchmarking Analysis

| Vendor | Material Grade | Cell Density (cells/in²) | Price per m² (USD) |

|---|---|---|---|

| HexCore Industries | Aluminum 5052 | 48 | $285 |

| SteelHive Solutions | AISI 304 | 64 | $412 |

| MetaHex Technologies | Titanium Gr.5 | 32 | $1,150 |

Precision Customization Frameworks

Adaptive manufacturing processes enable cell size adjustments from 3mm to 25mm, with thickness tolerances of ±0.05mm. A recent automotive project required:

- Variable cell densities across panel zones

- Integrated cooling channels for battery systems

- Anodized surface finishes with 15μm coating

Real-World Implementation Successes

The Dubai Solar Tower project utilized 8,400 m² of stainless steel honeycomb panels, achieving a 41% reduction in structural weight. In aviation, Boeing’s 787 Dreamliner decreased wing assembly mass by 28% using titanium honeycomb cores, translating to annual fuel savings of $2.1M per aircraft.

Economic and Operational Longevity

Lifecycle cost analyses demonstrate 14-year ROI for industrial installations, factoring in:

- 90% reduction in maintenance frequency

- 40% faster installation cycles

- 100% recyclability index

Honeycomb Metal Solutions: Pioneering Sustainable Infrastructure

With the global market projected to reach $9.7 billion by 2028 (Grand View Research), hexagonal metal sheet technology continues to redefine material science boundaries. Recent breakthroughs in graphene-coated variants have enhanced electrical conductivity by 300%, opening new frontiers in smart grid and EV battery applications.

(صفائح معدنية على شكل عسل النحل)

FAQS on صفائح معدنية على شكل عسل النحل

Q: What are honeycomb-shaped metal sheets used for?

A: Honeycomb-shaped metal sheets are commonly used in construction, aerospace, and automotive industries for lightweight structural support, acoustic insulation, and energy absorption due to their high strength-to-weight ratio.

Q: How durable are steel sheets with a honeycomb pattern?

A: Steel honeycomb sheets are highly durable, offering excellent resistance to corrosion, impact, and extreme temperatures, making them ideal for industrial and architectural applications requiring longevity.

Q: Can honeycomb-patterned metal panels be customized?

A: Yes, these panels can be tailored in size, thickness, and material (e.g., aluminum or stainless steel) to meet specific design or functional requirements for projects like façades or partitions.

Q: What advantages do honeycomb-structured metal sheets provide in architecture?

A: They combine aesthetic appeal with functionality, providing structural rigidity, thermal efficiency, and noise reduction while enabling creative designs for ceilings, cladding, or decorative elements.

Q: Are honeycomb-shaped steel sheets easy to install?

A: Yes, their modular design and lightweight nature simplify installation. Pre-fabricated options and standardized connectors further streamline the process for both small and large-scale projects.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025