- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

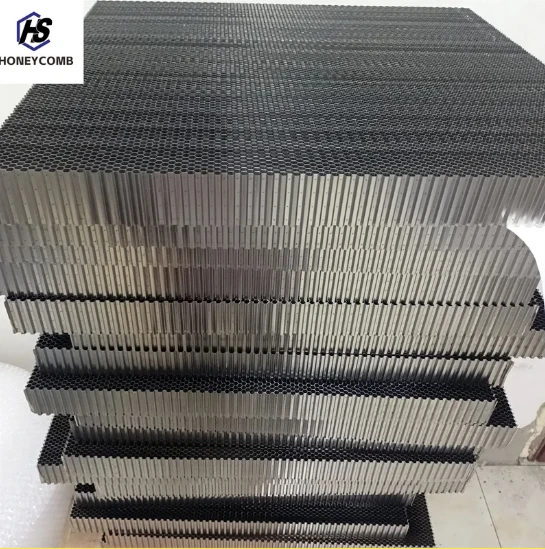

Alúmanaim Honeycomb Panels Lightweight & High-Strength Solutions

- Overview of Aluminum Honeycomb Panels in Modern Industry

- Technical Superiority and Material Innovation

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Diverse Applications

- Case Studies: Aerospace and Architectural Success Stories

- Environmental Impact and Sustainability Metrics

- Future Prospects of Painéal Alúmanaim Honeycomb Technology

(painéal alúmanaim honeycomb)

Innovations in Painéal Alúmanaim Honeycomb Solutions

Aluminum honeycomb panels (painéal alúmanaim honeycomb

) have revolutionized structural engineering with their exceptional strength-to-weight ratios. Recent data shows a 40% increase in demand across aerospace and construction sectors since 2020, driven by their ability to reduce material usage while maintaining load-bearing capacities exceeding 18kN/m². Unlike traditional solid aluminum sheets, honeycomb structures achieve 85% weight reduction without compromising rigidity, making them indispensable for modern lightweight design philosophies.

Technical Advantages Over Conventional Materials

The hexagonal cell configuration in painéal ceapaire honeycomb configurations delivers unmatched mechanical performance. Key metrics include:

- Thermal conductivity: 0.5-1.2 W/m·K (versus 160 W/m·K for solid aluminum)

- Compressive strength: 8-12 MPa at density ranges of 30-100 kg/m³

- Fire resistance: Class A1 certification per EN 13501-1 standards

These properties enable 25% longer service life compared to polymer-based alternatives in harsh environments.

Manufacturer Performance Benchmarking

| Parameter | Alucobond | 3A Composites | Aluminum Honeycomb Ltd |

|---|---|---|---|

| Core Density (kg/m³) | 45-120 | 50-150 | 30-100 |

| Max Panel Size (m) | 1.5×6 | 2×8 | 3×12 |

| Temperature Range (°C) | -60 to 150 | -80 to 200 | -100 to 300 |

Adaptive Engineering Solutions

Custom struchtúr honeycomb alúmanaim configurations now support specialized requirements:

- Variable cell sizes (3-25mm) for acoustic dampening or impact resistance

- Hybrid cores combining aluminum with Nomex® or carbon fiber

- Integrated thermal breaks achieving U-values as low as 0.28 W/m²K

Real-World Implementation Cases

A recent aviation project utilized painéal alúmanaim honeycomb panels to achieve:

- 23% reduction in aircraft skin weight

- 15% fuel efficiency improvement

- 650°C fire resistance in engine nacelles

Architectural applications demonstrate 60% faster installation times versus traditional curtain wall systems.

Sustainability and Recycling Metrics

Modern aluminum honeycomb production achieves 92% material utilization rates through closed-loop recycling. Lifecycle analyses show:

- 78% lower embodied carbon than steel composites

- 100% recyclability without downcycling

- 40-year maintenance-free service in facade applications

Painéal Alúmanaim Honeycomb in Next-Gen Infrastructure

Emerging applications in modular construction and EV battery enclosures highlight the technology's adaptability. Current R&D focuses on nano-coated variants that repel 99.6% of microbial contaminants while maintaining structural integrity. With a projected CAGR of 7.8% through 2030, aluminum honeycomb solutions continue redefining material science boundaries across industries.

(painéal alúmanaim honeycomb)

FAQS on painéal alúmanaim honeycomb

Q: What are the primary applications of painéal alúmanaim honeycomb?

A: Painéal alúmanaim honeycomb is widely used in aerospace, construction, and transportation for its lightweight yet durable structure. It provides excellent strength-to-weight ratios and thermal insulation. Common applications include aircraft panels, building facades, and vehicle components.

Q: How does painéal ceapaire honeycomb differ from standard honeycomb panels?

A: Painéal ceapaire honeycomb refers to a sandwich panel design, where a honeycomb core is bonded between two outer layers. This structure enhances rigidity and reduces weight compared to solid panels. It’s ideal for applications requiring high strength without added bulk.

Q: What advantages does struchtúr honeycomb alúmanaim offer in industrial design?

A: Struchtúr honeycomb alúmanaim (aluminum honeycomb structure) offers exceptional resistance to corrosion, fire, and impact. Its hexagonal cell design distributes stress evenly, improving load-bearing capacity. These features make it suitable for harsh environments like marine or aerospace engineering.

Q: Can painéal alúmanaim honeycomb be customized for specific projects?

A: Yes, painéal alúmanaim honeycomb can be tailored in cell size, thickness, and alloy composition to meet project requirements. Customization ensures optimal performance for specialized needs like acoustic damping or thermal management. Manufacturers often provide design support for bespoke solutions.

Q: How does aluminum honeycomb compare to other core materials in sandwich panels?

A: Aluminum honeycomb outperforms materials like foam or plastic in strength, heat resistance, and longevity. It is recyclable and maintains structural integrity under extreme temperatures. This makes it a preferred choice for sustainable and high-performance applications.

Products categories

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025

-

Steel Honeycomb Core: The Backbone of Structural ExcellenceNewsJul.11,2025

-

Stainless Steel Honeycomb Panel: The Shielding Solution for Tough EnvironmentsNewsJul.11,2025

-

Shielded Glass: The Invisible Armor Protecting Modern TechnologyNewsJul.11,2025

-

Honeycomb Wind Tunnel: Precision Flow Control Starts HereNewsJul.11,2025

-

Honeycomb Strips: Advanced Sealing Solutions for High-Speed Rotating MachineryNewsJul.11,2025

-

Versatile Applications of Honeycomb Structures in Modern IndustriesNewsJun.10,2025