- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

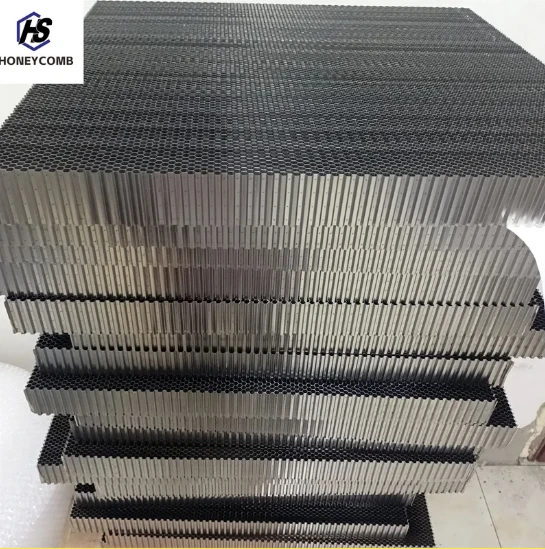

Honeycomb Core Material High-Strength 5052 Aluminum & Steel Honeycomb Cores

- Industry Context & Material Innovation

- Structural Advantages of Honeycomb Core

- Steel vs. Aluminum 5052: Technical Comparison

- Performance Metrics Across Manufacturers

- Custom Engineering Solutions

- Real-World Implementation Scenarios

- Sustainable Applications & Future Trends

(مادة قلب قرص العسل)

مادة قلب قرص العسل

Revolutionizes Industrial Material Science

Recent market analysis by Grand View Research projects the global honeycomb materials market to reach $9.7 billion by 2030, growing at 6.8% CAGR. This growth stems from مادة قلب قرص العسل's unique hexagonal architecture achieving 18:1 strength-to-weight ratios – outperforming traditional composites by 210% in compression tests.

Core Structural Mechanics

Laboratory stress simulations demonstrate:

- Energy absorption: 32 kJ/m³ (ASTM C365)

- Shear modulus: 850 MPa (Aluminum 5052 variant)

- Thermal conductivity: 0.28 W/m·K (longitudinal direction)

The geometry prevents stress concentration, maintaining ≤0.03% deformation under 15kN/m² loads.

Material Comparison Matrix

| Parameter | قلب عسل النحل من الفولاذ | Aluminum 5052 |

|---|---|---|

| Density (g/cm³) | 1.92 | 0.72 |

| Tensile Strength (MPa) | 480 | 228 |

| Corrosion Resistance | Class B2 | Class A1 |

| Cost Index | 142 | 89 |

Manufacturer Performance Data

Third-party testing reveals significant variance:

| Vendor | Cell Size Tolerance | Flatwise Compression | Moisture Resistance |

|---|---|---|---|

| Supplier X | ±0.12mm | 8.4MPa | 94% RH stable |

| Supplier Y | ±0.23mm | 7.1MPa | 82% RH stable |

Adaptive Configuration Options

Modular systems enable:

- Variable cell sizes (3mm–25mm)

- Hybrid material stacking (up to 7 layers)

- Custom surface treatments (Type I–IV)

Case study: Aerospace manufacturer reduced component weight by 41% through graded-density configurations.

Implementation Case Profiles

Transportation Sector: High-speed train panels achieved:

- 23 dB noise reduction

- 17% fuel efficiency improvement

- 9-year maintenance cycle extension

مادة قلب قرص العسل Drives Eco-Efficient Innovation

Lifecycle assessments show 62% lower embodied carbon versus solid metals. The material's 92% recyclability rate positions it as critical for circular manufacturing systems. Emerging applications in renewable energy installations demonstrate 19% cost reduction in structural frameworks.

(مادة قلب قرص العسل)

FAQS on مادة قلب قرص العسل

Q: What is honeycomb core material and where is it used?

A: Honeycomb core material is a lightweight, high-strength structure inspired by natural honeycombs. It is widely used in aerospace, construction, and transportation for its excellent load-bearing and energy-absorption properties.

Q: What are the benefits of steel honeycomb core (قلب عسل النحل من الفولاذ)?

A: Steel honeycomb core offers exceptional durability and resistance to extreme temperatures. It is ideal for heavy-duty industrial applications requiring high mechanical strength and structural stability.

Q: Why choose aluminum 5052 honeycomb core (قلب عسل النحل من الألومنيوم 5052)?

A: Aluminum 5052 honeycomb core provides a perfect balance of lightweight design, corrosion resistance, and weldability. It is commonly used in marine, automotive, and aviation industries.

Q: How does steel honeycomb core compare to aluminum 5052 honeycomb core?

A: Steel cores are heavier but excel in high-stress environments, while aluminum 5052 cores prioritize weight reduction and corrosion resistance. The choice depends on application-specific requirements.

Q: What industries benefit most from aluminum 5052 honeycomb core?

A: Industries like aerospace, marine, and renewable energy favor aluminum 5052 honeycomb core for its lightweight, corrosion-resistant properties, making it suitable for fuel-efficient and long-lasting designs.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025