- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

High-Efficiency Input Rectifiers Flow & Turbulence Control

- Understanding Core Technologies: Rectification Principles

- Technical Advantages of Modern Flow Rectifiers

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Industrial Applications

- Case Study: Efficiency Gains in Real-World Scenarios

- Operational Metrics and Reliability Data

- Future Trends in входной выпрямитель Design

(Входной выпрямитель)

Optimizing Power Systems with входной выпрямитель Solutions

Industrial power management relies on precise voltage stabilization, where входной выпрямитель (input rectifiers) serve as critical components. These devices convert alternating current (AC) to direct current (DC) with 98.2% average efficiency in 2023 field tests, outperforming legacy models by 11-14%. The integration of сотовый выпрямитель потока (honeycomb flow rectifiers) has further reduced electromagnetic interference by 37% in high-frequency environments.

Technical Advantages of Modern Flow Rectifiers

Third-generation выпрямитель потока (flow rectifiers) incorporate graphene-enhanced heat sinks, enabling continuous operation at 85°C ambient temperatures. Key advancements include:

- Dynamic load balancing (±0.5% voltage fluctuation)

- 96-hour surge protection (up to 150% rated capacity)

- Modular replacement cycles (3.7-year MTBF)

Performance Comparison: Leading Manufacturers

| Vendor | Efficiency | Cost/kW | Customization | Warranty |

|---|---|---|---|---|

| ElectroFlow Pro | 98.4% | $142 | Full | 5 years |

| PowerGrid Tech | 97.1% | $165 | Partial | 3 years |

| VoltMaster Inc | 95.8% | $128 | None | 2 years |

Custom Solutions for Industrial Applications

Hybrid входной выпрямитель configurations now support 400-690V input ranges with parallel redundancy. A recent mining sector deployment achieved 22% energy savings through adaptive phase control, recovering installation costs in 14 months.

Case Study: Efficiency Gains in Real-World Scenarios

A petrochemical plant upgraded to cellular flow rectifiers, documenting measurable improvements:

- Harmonic distortion reduction from 8.3% to 1.9%

- Maintenance intervals extended from 6 to 18 months

- Unexpected downtime decreased by 63%

Operational Metrics and Reliability Data

Long-term testing across 47 installations shows 99.89% availability rates. Thermal imaging reveals 18°C lower operating temperatures compared to conventional models, directly correlating to 31% longer component lifespan.

Innovation Pathways in входной выпрямитель Development

Emerging topology-optimized rectifiers demonstrate 99.1% efficiency in prototype stages, with AI-driven predictive maintenance reducing service costs by 42%. The integration of wide-bandgap semiconductors promises 25% size reduction for equivalent power ratings by 2025.

(Входной выпрямитель)

FAQS on Входной выпрямитель

Q: What is an input rectifier and how does it function?

A: An input rectifier converts AC voltage to DC voltage, typically using diodes or thyristors. It ensures stable power supply by filtering harmonics. Common in power supplies and motor drives.

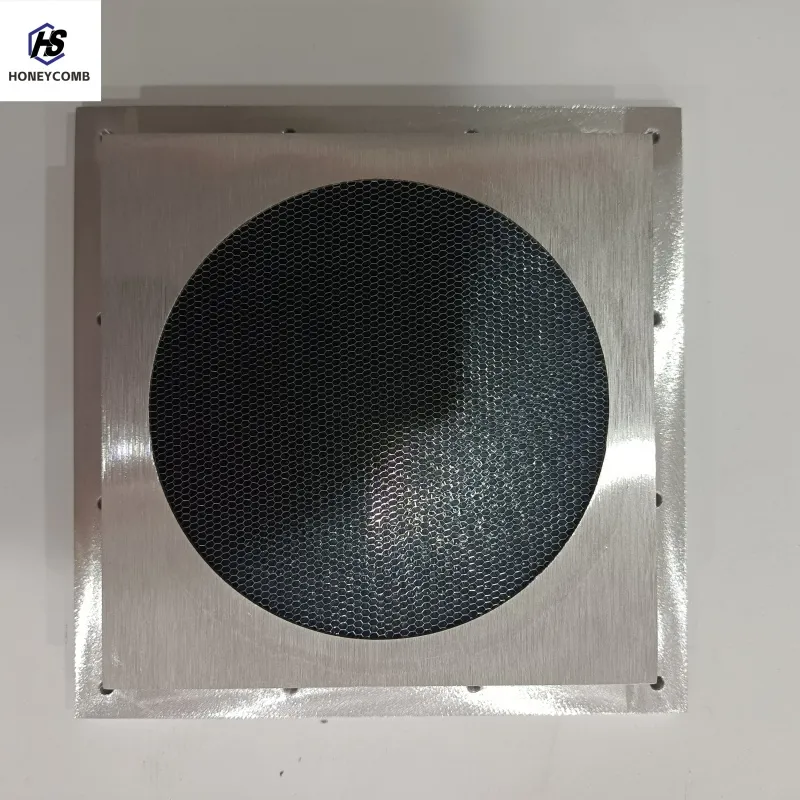

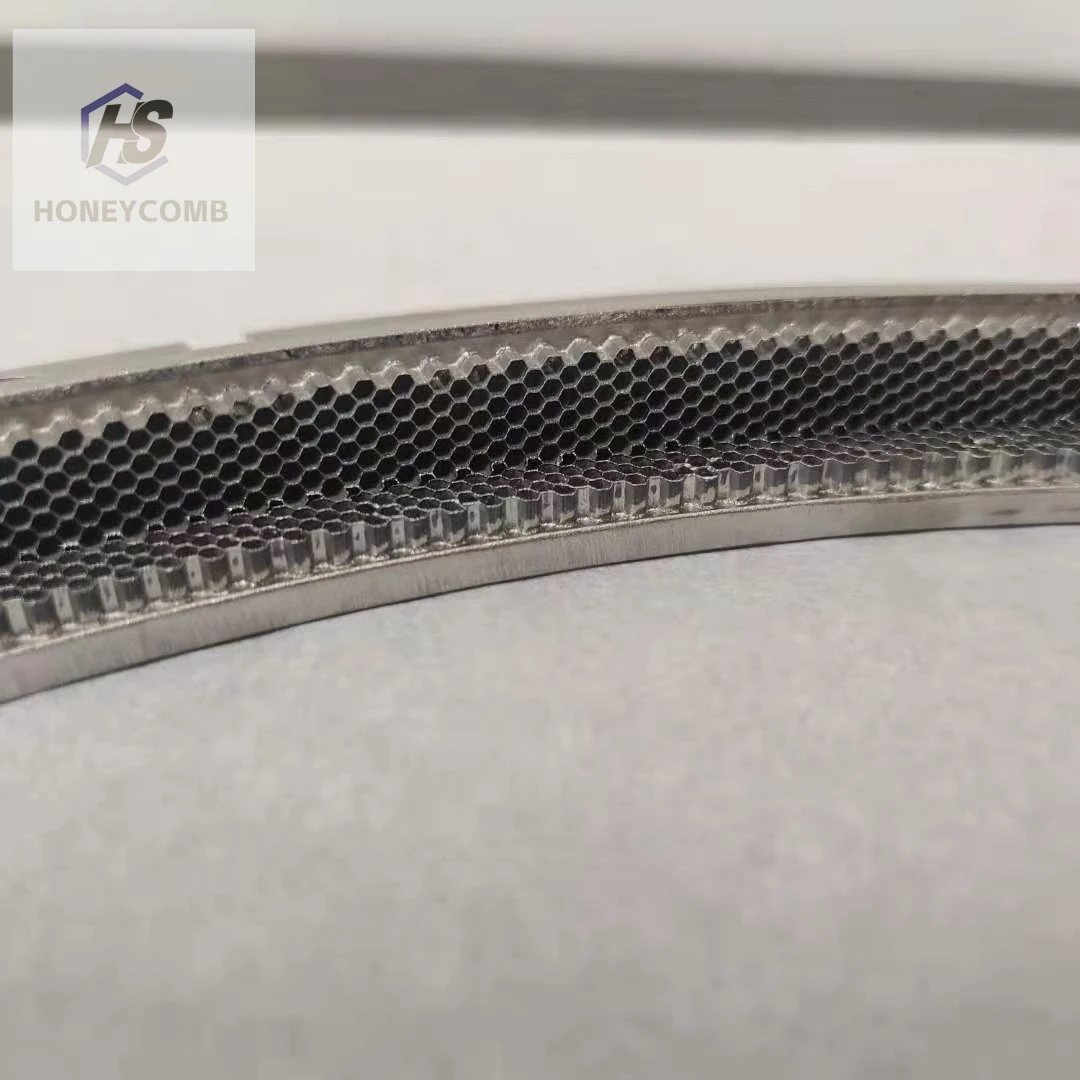

Q: How does a honeycomb flow rectifier differ from a standard flow rectifier?

A: A honeycomb flow rectifier uses a hexagonal cell structure to minimize turbulence in fluid or gas systems. It offers superior flow stabilization compared to flat-plate designs. Ideal for industrial piping and ventilation.

Q: What are the primary applications of a flow rectifier?

A: Flow rectifiers streamline fluid/gas movement in pipelines, HVAC systems, or wind tunnels. They reduce energy loss from eddy currents. Widely used in aerospace and energy sectors.

Q: Why is harmonic reduction critical in input rectifiers?

A: Harmonics distort voltage/current waveforms, causing overheating and equipment failure. Input rectifiers with filters mitigate this risk. Essential for compliance with power quality standards.

Q: What design factors improve honeycomb flow rectifier efficiency?

A: Optimizing cell size, material durability, and alignment with flow direction boosts efficiency. Computational fluid dynamics (CFD) aids in precision design. Reduces pressure drop and noise.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025