- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 10, 2025 08:36

Back to list

сплав сотовый лист

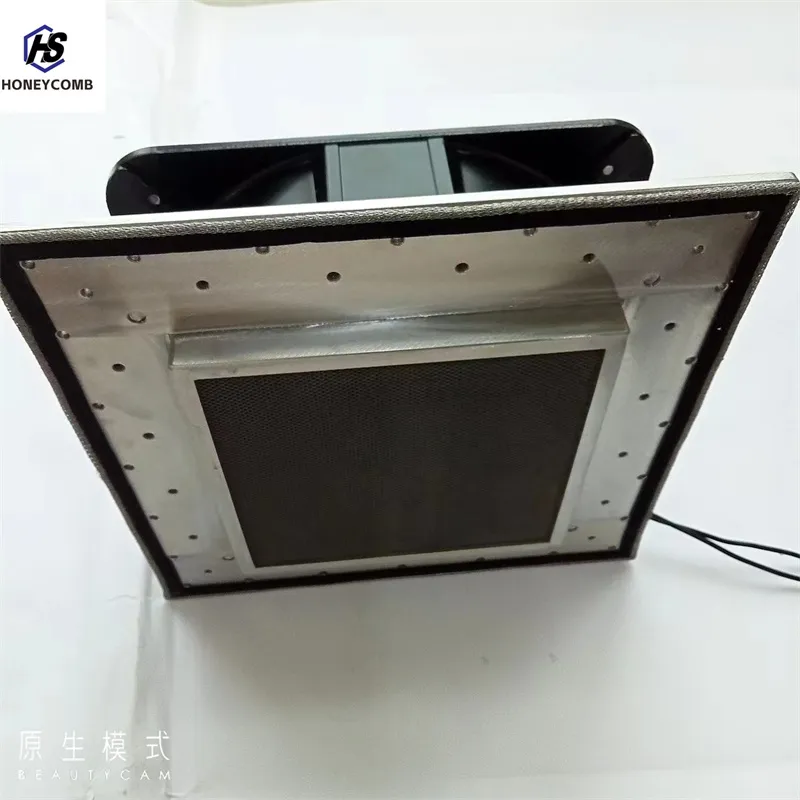

In the ever-evolving world of modern manufacturing, composite honeycomb sheets have emerged as a game-changer, offering unparalleled benefits across various industries. These innovative materials, characterized by their unique hexagonal structures, offer an impressive combination of strength, lightweight properties, and versatility. Here we delve into the essential aspects of composite honeycomb sheets, providing professional insight into their applications, benefits, and why they are becoming the material of choice for industry experts.

In the construction realm, composite honeycomb sheets are revolutionizing building materials. Architects and engineers leverage these sheets for their excellent thermal insulation properties and their ability to withstand environmental stress. This makes them suitable for both interior and exterior applications, from partition walls to roofing panels, providing sustainable solutions that align with modern building regulations aimed at reducing environmental impact. The expertise behind composite honeycomb sheets lies in advanced manufacturing techniques and a deep understanding of material science. By combining high-strength fibers and resins with sophisticated engineering processes, manufacturers produce sheets that meet exacting standards and specifications. This expertise ensures that each sheet delivers reliability and performance in even the most demanding applications, reinforcing their authoritative position in the industry. Trustworthiness in the use of composite honeycomb sheets is further enhanced by rigorous testing and quality control measures. Each batch undergoes comprehensive assessments to meet predefined criteria for strength, durability, and environmental resistance. These stringent evaluations not only ensure product reliability but also instill confidence among industry professionals who rely on these materials for critical applications. In conclusion, composite honeycomb sheets represent the pinnacle of modern material engineering, offering an unmatched combination of strength, lightweight attributes, and adaptability. Their integration across various industries underlines their significance and growth in modern material applications. As further innovations unfold, their role is expected to expand, driving advancements in technology and manufacturing. For industries seeking to enhance performance while adhering to stringent standards, composite honeycomb sheets provide a smart and reliable solution.

In the construction realm, composite honeycomb sheets are revolutionizing building materials. Architects and engineers leverage these sheets for their excellent thermal insulation properties and their ability to withstand environmental stress. This makes them suitable for both interior and exterior applications, from partition walls to roofing panels, providing sustainable solutions that align with modern building regulations aimed at reducing environmental impact. The expertise behind composite honeycomb sheets lies in advanced manufacturing techniques and a deep understanding of material science. By combining high-strength fibers and resins with sophisticated engineering processes, manufacturers produce sheets that meet exacting standards and specifications. This expertise ensures that each sheet delivers reliability and performance in even the most demanding applications, reinforcing their authoritative position in the industry. Trustworthiness in the use of composite honeycomb sheets is further enhanced by rigorous testing and quality control measures. Each batch undergoes comprehensive assessments to meet predefined criteria for strength, durability, and environmental resistance. These stringent evaluations not only ensure product reliability but also instill confidence among industry professionals who rely on these materials for critical applications. In conclusion, composite honeycomb sheets represent the pinnacle of modern material engineering, offering an unmatched combination of strength, lightweight attributes, and adaptability. Their integration across various industries underlines their significance and growth in modern material applications. As further innovations unfold, their role is expected to expand, driving advancements in technology and manufacturing. For industries seeking to enhance performance while adhering to stringent standards, composite honeycomb sheets provide a smart and reliable solution.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025