- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 14, 2025 16:21

Back to list

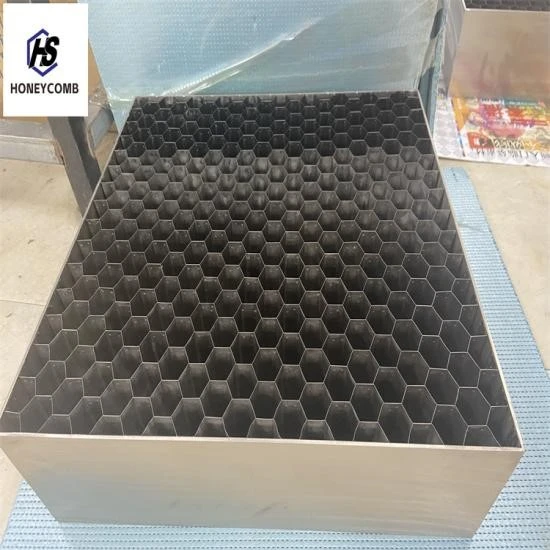

Hengshi Honeycomb Stainless Steel/Hastelloy Honeycomb Seals Strips Gas Seal Strips

Electromagnetic interference (EMI) poses a significant challenge in various industries, from telecommunications to healthcare. The innovative solution lies in EMI-shielded glass, a cutting-edge product that not only addresses these challenges but also enhances operational efficacy across multiple applications. This article explores the key features, benefits, and applications of EMI-shielded glass, supported by real-world experiences and expert insights.

Authoritativeness in the field of EMI protection is established through continuous research and development. Leading manufacturers collaborate with academic and industrial bodies to innovate and refine products. This partnership fosters cutting-edge advancements, with results often published in peer-reviewed journals. Such publications serve not only as a testament to the product's efficacy but also reinforce the trust placed in these solutions by industry professionals. Trustworthiness is paramount in product selection, particularly where EMI interference can have critical consequences. Selecting a supplier recognized for their commitment to quality and regulatory compliance gives assurance that the EMI-shielded glass will perform reliably under stress. Trust is further enhanced by certifications from recognized bodies, confirming adherence to stringent safety and performance criteria. Applications for EMI-shielded glass are expanding as the digital landscape evolves. In corporate settings, where sensitive data and intellectual property reside in digital form, securing these environments against electronic eavesdropping becomes as important as physical security. The installation of EMI-shielded glass windows and partitions in office spaces represents a proactive approach to safeguarding information integrity. In conclusion, EMI-shielded glass represents a blend of innovation and necessity, offering a viable solution to the pervasive issue of electromagnetic interference. By leveraging real-world experiences, expert engineering, authoritative research, and a commitment to trust, this product not only meets but exceeds the demands placed on it by modern technological environments. As industries continue to rely on sophisticated electronics, the role of EMI-shielded glass as a protective measure remains indispensable.

Authoritativeness in the field of EMI protection is established through continuous research and development. Leading manufacturers collaborate with academic and industrial bodies to innovate and refine products. This partnership fosters cutting-edge advancements, with results often published in peer-reviewed journals. Such publications serve not only as a testament to the product's efficacy but also reinforce the trust placed in these solutions by industry professionals. Trustworthiness is paramount in product selection, particularly where EMI interference can have critical consequences. Selecting a supplier recognized for their commitment to quality and regulatory compliance gives assurance that the EMI-shielded glass will perform reliably under stress. Trust is further enhanced by certifications from recognized bodies, confirming adherence to stringent safety and performance criteria. Applications for EMI-shielded glass are expanding as the digital landscape evolves. In corporate settings, where sensitive data and intellectual property reside in digital form, securing these environments against electronic eavesdropping becomes as important as physical security. The installation of EMI-shielded glass windows and partitions in office spaces represents a proactive approach to safeguarding information integrity. In conclusion, EMI-shielded glass represents a blend of innovation and necessity, offering a viable solution to the pervasive issue of electromagnetic interference. By leveraging real-world experiences, expert engineering, authoritative research, and a commitment to trust, this product not only meets but exceeds the demands placed on it by modern technological environments. As industries continue to rely on sophisticated electronics, the role of EMI-shielded glass as a protective measure remains indispensable.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025