- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 16, 2025 02:10

Back to list

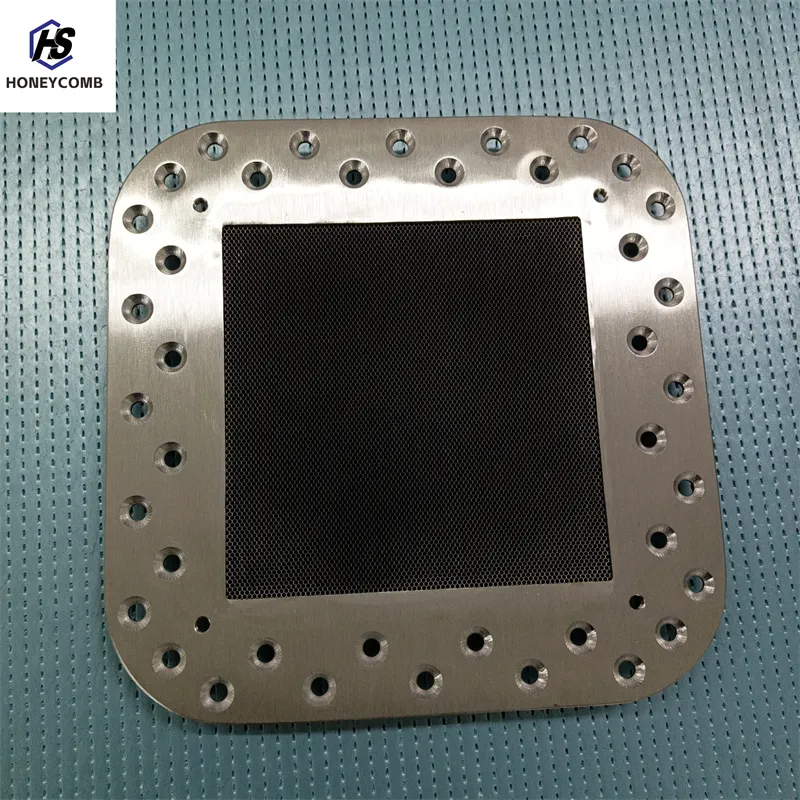

air straightener honeycomb

In the realm of advanced materials, ITO coated glass shines as a game-changer for various industries, providing a unique blend of electrical conductivity and optical transparency. Standing for Indium Tin Oxide, ITO, this specialized coating is meticulously applied on glass surfaces, transforming them into a crucial component for modern technology applications.

Authoritativeness in the field of ITO coated glass arises from continuous research and innovation. Institutions and companies leading the charge in this domain invest heavily in R&D to enhance the capabilities of ITO coatings. By leveraging cutting-edge materials and process technology, they achieve greater efficiency, reduced material costs, and improved durability of the coating—a necessity for modern electronic devices that undergo constant handling and environmental exposure. Trustworthiness is another cornerstone when considering ITO coated glass. Reliable performance over time, resistance to environmental wear, and consistent quality benchmarks set by leading manufacturers build confidence with consumers and industries alike. Certifications and compliance with international standards further cement the reputation of ITO coated glass as a trustworthy component in critical applications. In conclusion, ITO coated glass embodies a fusion of transparency and conductivity, meeting the ever-evolving demands of modern technology. By prioritizing expertise in its production, maintaining authoritative knowledge through innovative research, and ensuring trustworthiness in performance, industries can rely on ITO coated glass to drive future advancements. Its role as a cornerstone material in the development of sophisticated, efficient, and user-friendly products positions it not just as a component, but as a pivotal element in next-generation technological solutions.

Authoritativeness in the field of ITO coated glass arises from continuous research and innovation. Institutions and companies leading the charge in this domain invest heavily in R&D to enhance the capabilities of ITO coatings. By leveraging cutting-edge materials and process technology, they achieve greater efficiency, reduced material costs, and improved durability of the coating—a necessity for modern electronic devices that undergo constant handling and environmental exposure. Trustworthiness is another cornerstone when considering ITO coated glass. Reliable performance over time, resistance to environmental wear, and consistent quality benchmarks set by leading manufacturers build confidence with consumers and industries alike. Certifications and compliance with international standards further cement the reputation of ITO coated glass as a trustworthy component in critical applications. In conclusion, ITO coated glass embodies a fusion of transparency and conductivity, meeting the ever-evolving demands of modern technology. By prioritizing expertise in its production, maintaining authoritative knowledge through innovative research, and ensuring trustworthiness in performance, industries can rely on ITO coated glass to drive future advancements. Its role as a cornerstone material in the development of sophisticated, efficient, and user-friendly products positions it not just as a component, but as a pivotal element in next-generation technological solutions.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025