- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 19, 2025 00:36

Back to list

сотовые уплотнения

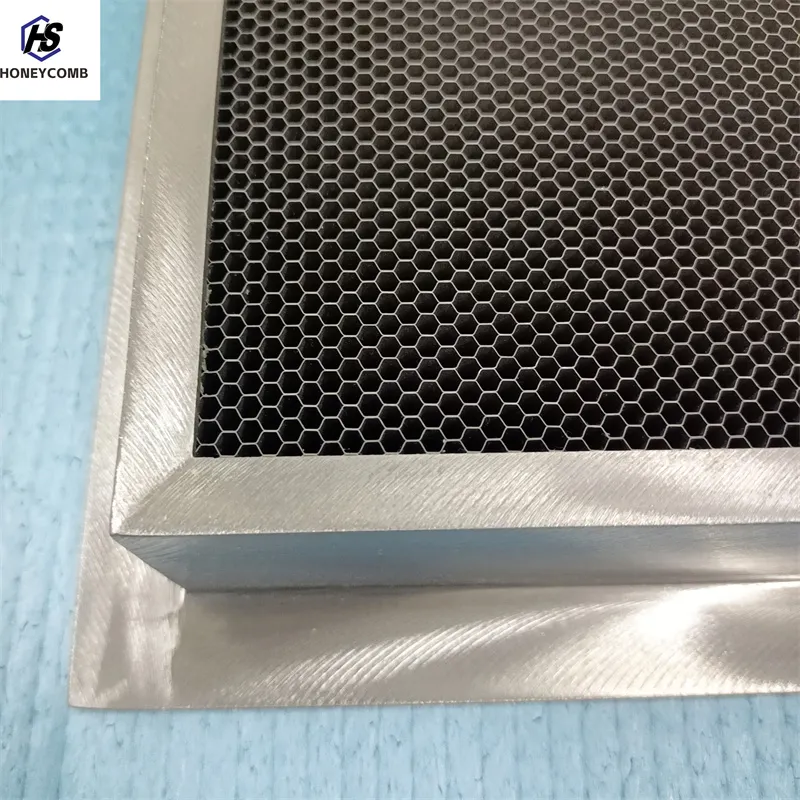

Cellular seals, also known as cellular gaskets, have become increasingly significant in a variety of industries, demonstrating their versatility and reliability in applications ranging from automotive to aerospace. These seals act as barriers that prevent leaks, control pressure, and ensure the optimal performance of diverse systems.

The manufacturing process for cellular seals emphasizes precision and quality control to meet stringent industrial standards. State-of-the-art technology is employed to produce seals that conform to specific dimensional and performance requirements, ensuring reliability and durability in application. The involvement of experienced engineers and quality assurance specialists in this process underscores the importance of expertise and authority in producing high-performance cellular seals. Trustworthiness in the performance of cellular seals is further enhanced by rigorous testing protocols. Seals undergo extensive fatigue testing, thermal cycling, and pressure testing before deployment in their intended environments. These tests simulate real-world scenarios, allowing manufacturers to guarantee the seals’ performance under expected operational conditions. Such rigorous testing criteria are crucial for building the confidence of end-users in the safety and reliability of cellular seals. User experience with cellular seals consistently affirms their effectiveness and ease of use. Many users report that the installation process of cellular seals is straightforward, requiring minimal technical expertise, which reduces downtime during maintenance or assembly processes. Moreover, businesses have reported noticeable improvements in system efficiency and reduction in maintenance costs due to the enhanced sealing capabilities and durability of cellular seals. In conclusion, the innovation in cellular seals is emblematic of how advanced material science and engineering can produce components that significantly enhance industrial applications. Their impressive adaptability across various sectors, combined with their superior performance characteristics, has made cellular seals an indispensable part of modern engineering. As industries continue to evolve, the demand for high-quality cellular seals will remain robust, driving continuous innovation and expertise in this specialized field.

The manufacturing process for cellular seals emphasizes precision and quality control to meet stringent industrial standards. State-of-the-art technology is employed to produce seals that conform to specific dimensional and performance requirements, ensuring reliability and durability in application. The involvement of experienced engineers and quality assurance specialists in this process underscores the importance of expertise and authority in producing high-performance cellular seals. Trustworthiness in the performance of cellular seals is further enhanced by rigorous testing protocols. Seals undergo extensive fatigue testing, thermal cycling, and pressure testing before deployment in their intended environments. These tests simulate real-world scenarios, allowing manufacturers to guarantee the seals’ performance under expected operational conditions. Such rigorous testing criteria are crucial for building the confidence of end-users in the safety and reliability of cellular seals. User experience with cellular seals consistently affirms their effectiveness and ease of use. Many users report that the installation process of cellular seals is straightforward, requiring minimal technical expertise, which reduces downtime during maintenance or assembly processes. Moreover, businesses have reported noticeable improvements in system efficiency and reduction in maintenance costs due to the enhanced sealing capabilities and durability of cellular seals. In conclusion, the innovation in cellular seals is emblematic of how advanced material science and engineering can produce components that significantly enhance industrial applications. Their impressive adaptability across various sectors, combined with their superior performance characteristics, has made cellular seals an indispensable part of modern engineering. As industries continue to evolve, the demand for high-quality cellular seals will remain robust, driving continuous innovation and expertise in this specialized field.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025