- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 19, 2025 01:51

Back to list

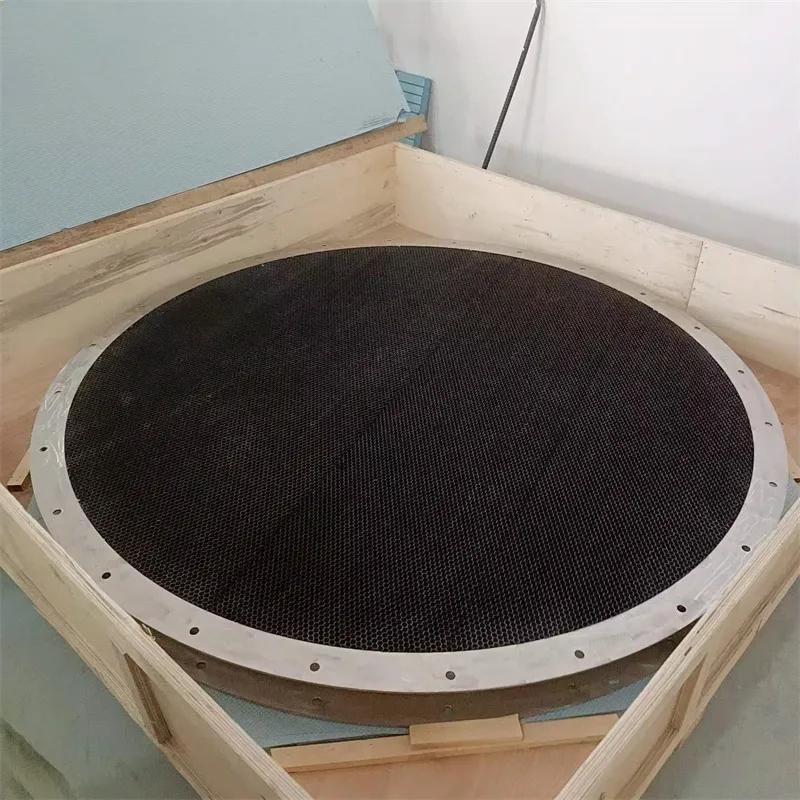

герметичные соты

For years, the concept of airtight honeycombs (герметичные соты) has intrigued both engineers and nature enthusiasts due to their remarkable efficiency and versatility. As a product rooted in both natural inspiration and technological innovation, airtight honeycombs showcase exceptional qualities suitable for various industries, including construction, aerospace, and environmental engineering.

The authoritative nature of these products is further solidified by numerous academic studies and industry endorsements. Research indicates that airtight honeycombs not only improve energy efficiency by up to 30% when compared to traditional materials but also enhance the structural integrity of frameworks where they are employed. This data solidifies their role as indispensable components in eco-friendly and resilient construction methodologies. Trustworthiness in the context of airtight honeycombs is pivotal. With global imperatives toward sustainability, manufacturers are increasingly transparent about their sourcing and production processes. Adopting eco-friendly materials and reducing waste, they contribute to a circular economy. Consumers are assured of the quality and sustainability footprints through certifications and compliance with international building and safety codes. Such measures significantly boost consumer confidence and market adoption. Experience, as shared by industry professionals, forms the backbone of innovation in airtight honeycomb design and application. Engineers and architects have shared numerous case studies where the implementation of these structures has not only met but exceeded client expectations, offering practical insights into their long-term benefits and ease of integration. In concluding, airtight honeycombs embody a perfect amalgamation of nature-inspired design and cutting-edge technology. While their technical specifications and applications are rich and varied, the continued dedication to research and sustainable practices ensures that these structures will remain at the forefront of innovative solutions across multiple sectors. Whether it is the skyscrapers that touch the sky or the spacecraft that explore the vast unknown, airtight honeycombs are indispensable in shaping the future of engineering marvels.

The authoritative nature of these products is further solidified by numerous academic studies and industry endorsements. Research indicates that airtight honeycombs not only improve energy efficiency by up to 30% when compared to traditional materials but also enhance the structural integrity of frameworks where they are employed. This data solidifies their role as indispensable components in eco-friendly and resilient construction methodologies. Trustworthiness in the context of airtight honeycombs is pivotal. With global imperatives toward sustainability, manufacturers are increasingly transparent about their sourcing and production processes. Adopting eco-friendly materials and reducing waste, they contribute to a circular economy. Consumers are assured of the quality and sustainability footprints through certifications and compliance with international building and safety codes. Such measures significantly boost consumer confidence and market adoption. Experience, as shared by industry professionals, forms the backbone of innovation in airtight honeycomb design and application. Engineers and architects have shared numerous case studies where the implementation of these structures has not only met but exceeded client expectations, offering practical insights into their long-term benefits and ease of integration. In concluding, airtight honeycombs embody a perfect amalgamation of nature-inspired design and cutting-edge technology. While their technical specifications and applications are rich and varied, the continued dedication to research and sustainable practices ensures that these structures will remain at the forefront of innovative solutions across multiple sectors. Whether it is the skyscrapers that touch the sky or the spacecraft that explore the vast unknown, airtight honeycombs are indispensable in shaping the future of engineering marvels.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025