- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 20, 2025 07:18

Back to list

ختم قرص العسل توربينات الغاز

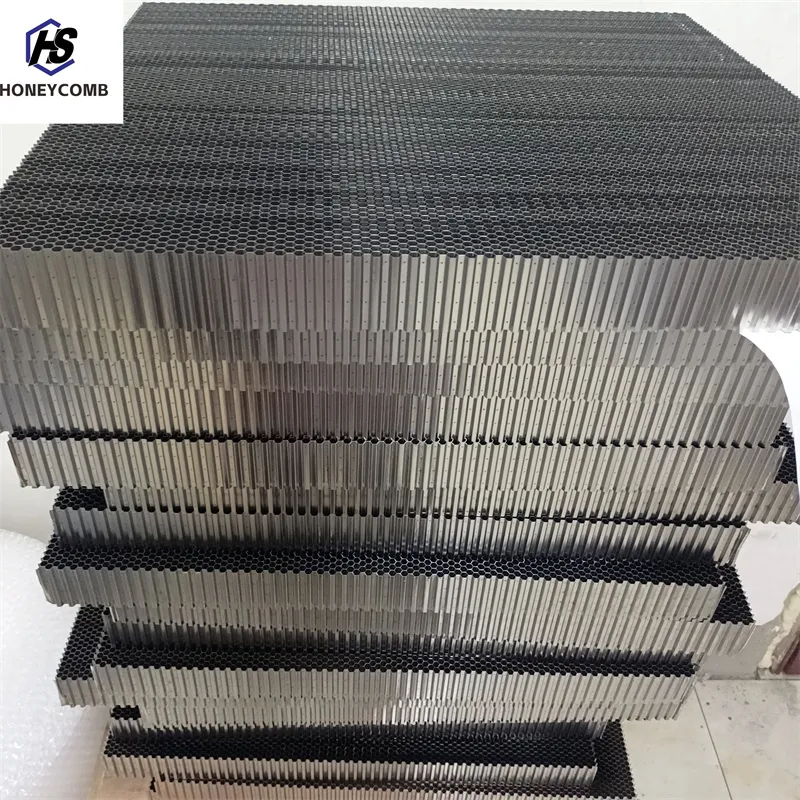

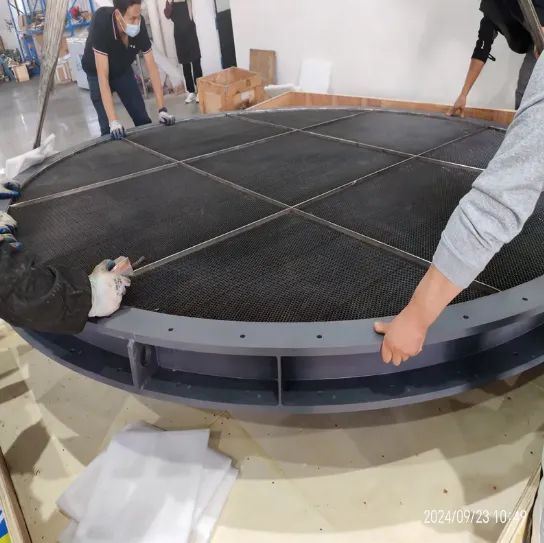

Gas turbine technology has made considerable strides over recent decades, and one of the most innovative advancements is in the domain of sealing mechanisms, specifically the honeycomb seal. Honeycomb seals in gas turbines serve to optimize performance, enhance efficiency, and extend the operational lifespan of the machinery. This article delves into the real-world experiences, specialized knowledge, and authoritative insights surrounding honeycomb seals in gas turbines, drawing attention to their undeniable value and reliability.

The authoritative nature of honeycomb seals is further reinforced by their widespread adoption in the industry. Leading manufacturers such as General Electric, Siemens, and Rolls-Royce have integrated honeycomb seals into their gas turbines, demonstrating the seals' trustworthiness and high regard in the industry. These companies have conducted extensive research and testing to verify that honeycomb seals meet the rigorous demands of modern turbine operation. For professionals looking to upgrade or maintain their gas turbines, relying on these insights from industry leaders provides added peace of mind regarding the reliability and efficiency of honeycomb seals. Trustworthiness is a critical component when considering any turbine technology, and honeycomb seals do not disappoint. Field studies corroborate the claims of enhanced efficiency and durability, with numerous instances of successful implementation across various industries. Power generation facilities and aviation sectors alike report consistent performance improvements and maintenance cost reductions directly attributed to the integration of honeycomb seals. Furthermore, the evolution of honeycomb seal technology continues, with researchers exploring new materials and configurations to increase performance even further. This continual advancement ensures that honeycomb seals remain at the forefront of sealing technology within gas turbines. For instance, research into composite materials aims to reduce weight and enhance thermal properties, positioning honeycomb seals as a future-proof choice for modern turbine needs. In conclusion, honeycomb seals represent a sophisticated solution to one of the most challenging aspects of gas turbine operation. Through practical application, expert development, authoritative validation, and proven trustworthiness, they provide unmatched benefits in efficiency and durability. Their adoption by top industry players and continued evolution highlight their critical role in advancing gas turbine technology. As industries strive for more efficient and reliable power solutions, honeycomb seals are poised to remain a pillar of gas turbine design, ensuring optimal performance both now and in the future.

The authoritative nature of honeycomb seals is further reinforced by their widespread adoption in the industry. Leading manufacturers such as General Electric, Siemens, and Rolls-Royce have integrated honeycomb seals into their gas turbines, demonstrating the seals' trustworthiness and high regard in the industry. These companies have conducted extensive research and testing to verify that honeycomb seals meet the rigorous demands of modern turbine operation. For professionals looking to upgrade or maintain their gas turbines, relying on these insights from industry leaders provides added peace of mind regarding the reliability and efficiency of honeycomb seals. Trustworthiness is a critical component when considering any turbine technology, and honeycomb seals do not disappoint. Field studies corroborate the claims of enhanced efficiency and durability, with numerous instances of successful implementation across various industries. Power generation facilities and aviation sectors alike report consistent performance improvements and maintenance cost reductions directly attributed to the integration of honeycomb seals. Furthermore, the evolution of honeycomb seal technology continues, with researchers exploring new materials and configurations to increase performance even further. This continual advancement ensures that honeycomb seals remain at the forefront of sealing technology within gas turbines. For instance, research into composite materials aims to reduce weight and enhance thermal properties, positioning honeycomb seals as a future-proof choice for modern turbine needs. In conclusion, honeycomb seals represent a sophisticated solution to one of the most challenging aspects of gas turbine operation. Through practical application, expert development, authoritative validation, and proven trustworthiness, they provide unmatched benefits in efficiency and durability. Their adoption by top industry players and continued evolution highlight their critical role in advancing gas turbine technology. As industries strive for more efficient and reliable power solutions, honeycomb seals are poised to remain a pillar of gas turbine design, ensuring optimal performance both now and in the future.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025