- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 22, 2025 00:37

Back to list

قرص العسل الفولاذي المقاوم للصدأ

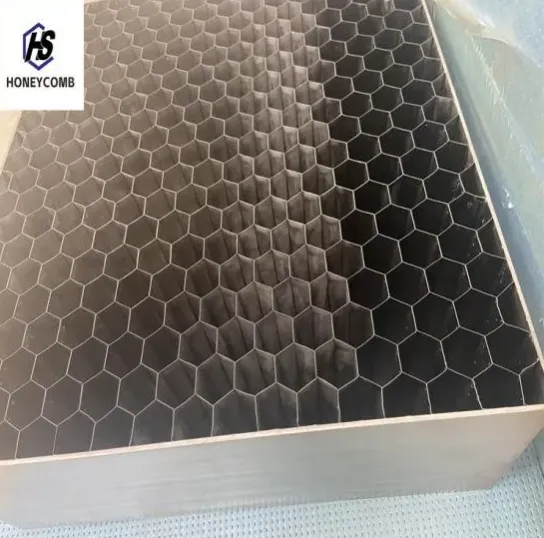

Stainless steel honeycomb panels are revolutionizing the construction and design industry due to their unique blend of strength, flexibility, and lightweight characteristics. These panels are a prime choice for architects and builders who demand high-quality materials that maintain aesthetic appeal while offering superior performance.

Stainless steel honeycomb panels’ fire-resistant properties further solidify their authority within the material industry. Classified as non-combustible, these panels provide an additional safety layer in buildings, helping slow down fire spread. Compliance with international fire safety standards makes them a preferred choice for public buildings, offering peace of mind to stakeholders concerned with safety and regulatory adherence. Trust in stainless steel honeycomb panels grows from their track record. Projects spanning from high-speed trains to architectural masterpieces attest to their reliability. For instance, consider how their use in transport not only improves fuel efficiency due to reduced vehicle weight but also increases passenger safety due to enhanced impact resistance. These real-world applications underscore the panels' viability and enduring performance. Selecting stainless steel honeycomb panels also aligns with sustainability goals, another factor which enhances their trustworthiness. Their composition facilitates recyclability, and long lifespan reduces the need for frequent replacements, thus curbing material waste and contributing to environmental conservation efforts. For organizations aimed at reducing carbon footprints, this eco-friendly attribute complements modern sustainable building practices. In summary, stainless steel honeycomb panels offer a formidable combination of aesthetics, strength, and sustainability, making them indispensable in contemporary construction and design. Experience from using these panels in various applications highlights their effectiveness and versatility. Expertise in their application ensures optimal performance, while authoritative endorsements by professionals and trustworthy certifications affirm their reliability and safety. As demands on materials continue to evolve, stainless steel honeycomb panels remain at the forefront, constantly proving their worth across numerous fields.

Stainless steel honeycomb panels’ fire-resistant properties further solidify their authority within the material industry. Classified as non-combustible, these panels provide an additional safety layer in buildings, helping slow down fire spread. Compliance with international fire safety standards makes them a preferred choice for public buildings, offering peace of mind to stakeholders concerned with safety and regulatory adherence. Trust in stainless steel honeycomb panels grows from their track record. Projects spanning from high-speed trains to architectural masterpieces attest to their reliability. For instance, consider how their use in transport not only improves fuel efficiency due to reduced vehicle weight but also increases passenger safety due to enhanced impact resistance. These real-world applications underscore the panels' viability and enduring performance. Selecting stainless steel honeycomb panels also aligns with sustainability goals, another factor which enhances their trustworthiness. Their composition facilitates recyclability, and long lifespan reduces the need for frequent replacements, thus curbing material waste and contributing to environmental conservation efforts. For organizations aimed at reducing carbon footprints, this eco-friendly attribute complements modern sustainable building practices. In summary, stainless steel honeycomb panels offer a formidable combination of aesthetics, strength, and sustainability, making them indispensable in contemporary construction and design. Experience from using these panels in various applications highlights their effectiveness and versatility. Expertise in their application ensures optimal performance, while authoritative endorsements by professionals and trustworthy certifications affirm their reliability and safety. As demands on materials continue to evolve, stainless steel honeycomb panels remain at the forefront, constantly proving their worth across numerous fields.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025