- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 26, 2025 00:03

Back to list

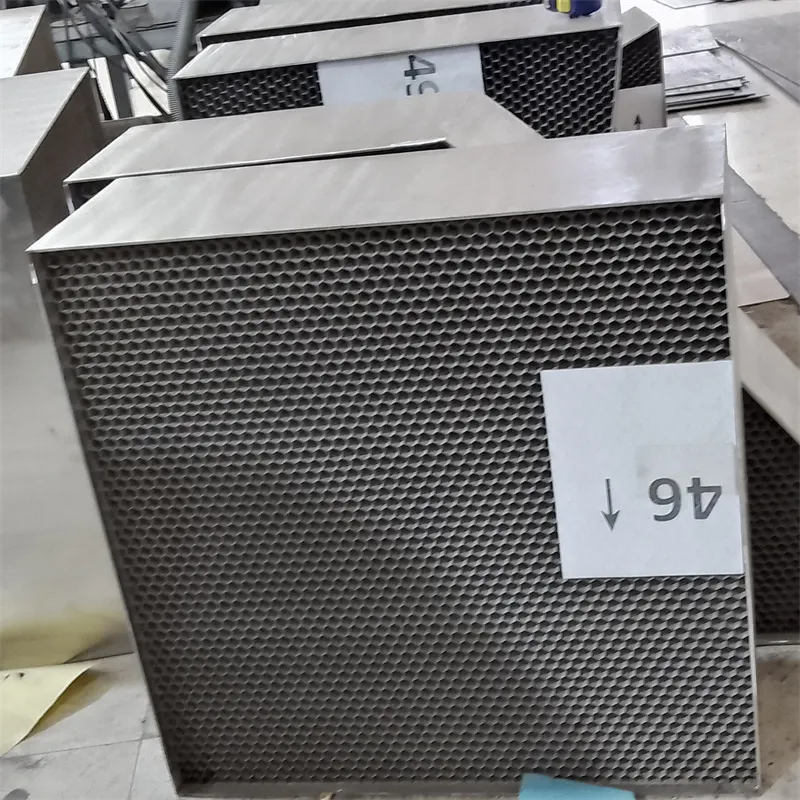

Hengshi Honeycomb Stainless Steel/Hastelloy Honeycomb Seals Strips Gas Seal Strips

The honeycomb vent, an innovative and essential component in various industries, is transforming how we think about efficient airflow and ventilation. By harnessing the natural geometry of the honeycomb structure, these vents offer remarkable improvements in performance and utility. As industries and consumers continue to prioritize sustainability and energy efficiency, understanding the mechanics and benefits of honeycomb vents is crucial.

From an engineering perspective, honeycomb vents present a remarkable opportunity to innovate. These structures can be customized to meet specific requirements, adjusting parameters like cell size, material composition, and thickness to tailor performance characteristics precisely to the needs of the application. This adaptability not only enhances the utility of honeycomb vents but also enables engineers and designers to push the boundaries of conventional ventilation systems, opening new avenues for development across multiple sectors. Moreover, honeycomb vents contribute to improved indoor air quality, a crucial factor for both public health and workplace safety. By facilitating efficient air exchange, these vents help remove pollutants and maintain optimal airflow, reducing the risks associated with poor air quality. This aspect is gaining attention in sectors ranging from healthcare to manufacturing, where the implications of air quality are significant. Taking into account the life-cycle benefits of honeycomb vents, they represent a sustainable choice. The manufacturing processes for these vents often involve eco-friendly materials and maintain a low environmental impact. Furthermore, their durability means fewer resources are needed over time for replacements and repairs, reducing waste and further supporting sustainability goals. In summary, honeycomb vents are not merely a functional component but a testament to the intersection of engineering ingenuity and natural design principles. Their application across various industries exemplifies how innovative solutions can enhance performance while supporting sustainability and efficiency. By prioritizing these advanced ventilation solutions, companies are not only investing in their immediate operational needs but are also aligning with broader environmental and economic objectives. Such strategic choices reflect a commitment to leveraging technology to solve complex challenges, ensuring that honeycomb vents remain a vital resource in modern infrastructure development.

From an engineering perspective, honeycomb vents present a remarkable opportunity to innovate. These structures can be customized to meet specific requirements, adjusting parameters like cell size, material composition, and thickness to tailor performance characteristics precisely to the needs of the application. This adaptability not only enhances the utility of honeycomb vents but also enables engineers and designers to push the boundaries of conventional ventilation systems, opening new avenues for development across multiple sectors. Moreover, honeycomb vents contribute to improved indoor air quality, a crucial factor for both public health and workplace safety. By facilitating efficient air exchange, these vents help remove pollutants and maintain optimal airflow, reducing the risks associated with poor air quality. This aspect is gaining attention in sectors ranging from healthcare to manufacturing, where the implications of air quality are significant. Taking into account the life-cycle benefits of honeycomb vents, they represent a sustainable choice. The manufacturing processes for these vents often involve eco-friendly materials and maintain a low environmental impact. Furthermore, their durability means fewer resources are needed over time for replacements and repairs, reducing waste and further supporting sustainability goals. In summary, honeycomb vents are not merely a functional component but a testament to the intersection of engineering ingenuity and natural design principles. Their application across various industries exemplifies how innovative solutions can enhance performance while supporting sustainability and efficiency. By prioritizing these advanced ventilation solutions, companies are not only investing in their immediate operational needs but are also aligning with broader environmental and economic objectives. Such strategic choices reflect a commitment to leveraging technology to solve complex challenges, ensuring that honeycomb vents remain a vital resource in modern infrastructure development.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025