- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 02, 2025 04:57

Back to list

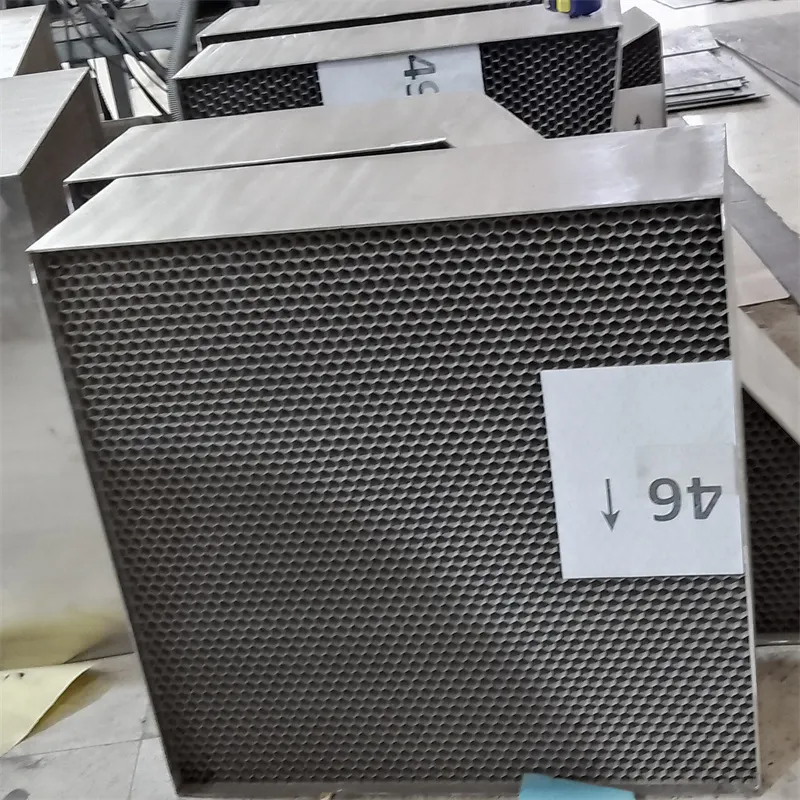

Stainless Steel EMI Honeycomb Vent Panels for Shielded Tent

Stainless steel honeycomb sandwich panels have emerged as a revolutionary product in the architectural and industrial sectors. Known for their lightweight structure, high strength, and corrosion resistance, these panels are ideal for a variety of applications. This article explores the multifaceted benefits, uses, and innovative nature of stainless steel honeycomb sandwich panels, highlighting their growing prominence in modern manufacturing and construction.

Authoritativeness in the market is achieved through rigorous testing and quality assurance processes. Stainless steel honeycomb sandwich panels are subject to stringent industry standards and regulations, ensuring they meet the high-performance criteria required for safety and reliability. Renowned certification bodies frequently conduct assessments to verify that these panels are capable of withstanding environmental and mechanical challenges. Trustworthiness is further underscored by the long-term performance of these panels in numerous high-stakes projects worldwide. Clients and industry leaders regularly report on their positive experiences, citing reduced installation times, cost savings, and exceptional performance. This feedback loop not only builds trust with potential new clients but also drives continued innovation and improvement within the industry. In light of these factors, the demand for stainless steel honeycomb sandwich panels is set to rise. As industries increasingly move towards sustainable and efficient building practices, these panels offer a compelling solution. Their combination of lightness, strength, versatility, and eco-friendliness makes them an unparalleled choice for modern construction and industrial needs. Adopting stainless steel honeycomb sandwich panels is not just an investment in a durable product but a commitment to forward-thinking and sustainable practices. Whether in towering skyscrapers or integral parts of a spacecraft, these panels represent a perfect blend of elegance, functionality, and innovation, providing stakeholders with the assurance of quality and performance that modern applications demand.

Authoritativeness in the market is achieved through rigorous testing and quality assurance processes. Stainless steel honeycomb sandwich panels are subject to stringent industry standards and regulations, ensuring they meet the high-performance criteria required for safety and reliability. Renowned certification bodies frequently conduct assessments to verify that these panels are capable of withstanding environmental and mechanical challenges. Trustworthiness is further underscored by the long-term performance of these panels in numerous high-stakes projects worldwide. Clients and industry leaders regularly report on their positive experiences, citing reduced installation times, cost savings, and exceptional performance. This feedback loop not only builds trust with potential new clients but also drives continued innovation and improvement within the industry. In light of these factors, the demand for stainless steel honeycomb sandwich panels is set to rise. As industries increasingly move towards sustainable and efficient building practices, these panels offer a compelling solution. Their combination of lightness, strength, versatility, and eco-friendliness makes them an unparalleled choice for modern construction and industrial needs. Adopting stainless steel honeycomb sandwich panels is not just an investment in a durable product but a commitment to forward-thinking and sustainable practices. Whether in towering skyscrapers or integral parts of a spacecraft, these panels represent a perfect blend of elegance, functionality, and innovation, providing stakeholders with the assurance of quality and performance that modern applications demand.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025