- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 03, 2025 01:41

Back to list

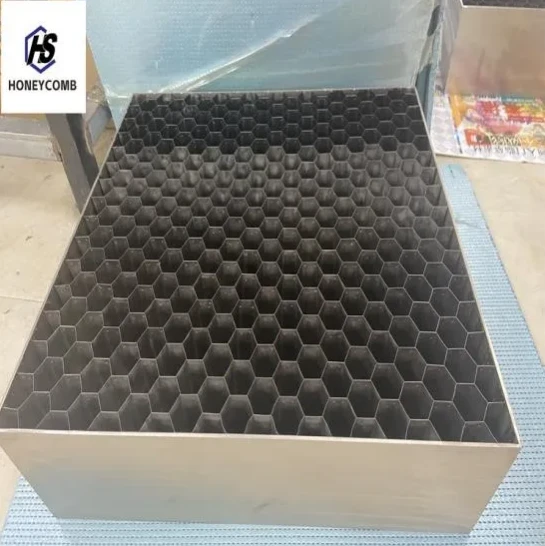

ألواح شبكية من الفولاذ المقاوم للصدأ

Stainless steel mesh panels are rapidly becoming the material of choice for architects, builders, and DIY enthusiasts alike. These versatile panels offer a unique blend of durability, aesthetic appeal, and practicality, making them indispensable in various applications. Here's an exploration into why stainless steel mesh panels stand out and how they meet the stringent requirements of modern construction and design.

Looking at practical applications, recent projects demonstrate the transformative effect of these panels. In urban residential complexes, they are used to create stylish balcony railings that offer security without sacrificing the view. In educational and health institutions, stainless steel mesh panels promote safety and hygiene with ease of cleaning and non-toxicity, a crucial factor in environments inclined towards cleanliness and high foot traffic. Their practicality extends to security purposes as well. Facilities that require enhanced security measures, such as data centers or exclusive residential communities, can utilize these panels for robust fencing and entry-point fortifications. Stainless steel mesh panels effectively balance security with visibility, allowing for monitoring without imposing a fortress-like appearance. To maintain the integrity and appearance of stainless steel mesh panels, regular cleaning with mild soap and water suffice, eliminating the need for specialized chemicals or treatments. This low-maintenance advantage underscores their cost-effectiveness over their lifespan, enhancing their appeal to budget-conscious projects that do not compromise on quality. Choosing stainless steel mesh panels signifies a commitment to quality, innovation, and sustainability. For experts in the construction, architectural, and manufacturing fields, these panels offer nonpareil reliability and performance. Trusted by industry veterans and innovators alike, their popularity is a testament to their capabilities and the trust that users place in them. In conclusion, stainless steel mesh panels are not just a trend—they represent a long-term solution to modern construction needs. Balancing aesthetics, durability, and environmental considerations, they meet the high standards set by today’s ambitious building projects. Their continued use across diverse applications is a clear indication of their unrivaled utility in the competitive landscape of construction materials.

Looking at practical applications, recent projects demonstrate the transformative effect of these panels. In urban residential complexes, they are used to create stylish balcony railings that offer security without sacrificing the view. In educational and health institutions, stainless steel mesh panels promote safety and hygiene with ease of cleaning and non-toxicity, a crucial factor in environments inclined towards cleanliness and high foot traffic. Their practicality extends to security purposes as well. Facilities that require enhanced security measures, such as data centers or exclusive residential communities, can utilize these panels for robust fencing and entry-point fortifications. Stainless steel mesh panels effectively balance security with visibility, allowing for monitoring without imposing a fortress-like appearance. To maintain the integrity and appearance of stainless steel mesh panels, regular cleaning with mild soap and water suffice, eliminating the need for specialized chemicals or treatments. This low-maintenance advantage underscores their cost-effectiveness over their lifespan, enhancing their appeal to budget-conscious projects that do not compromise on quality. Choosing stainless steel mesh panels signifies a commitment to quality, innovation, and sustainability. For experts in the construction, architectural, and manufacturing fields, these panels offer nonpareil reliability and performance. Trusted by industry veterans and innovators alike, their popularity is a testament to their capabilities and the trust that users place in them. In conclusion, stainless steel mesh panels are not just a trend—they represent a long-term solution to modern construction needs. Balancing aesthetics, durability, and environmental considerations, they meet the high standards set by today’s ambitious building projects. Their continued use across diverse applications is a clear indication of their unrivaled utility in the competitive landscape of construction materials.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025