- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 04, 2025 00:39

Back to list

ईएमआई हनीकॉम्ब

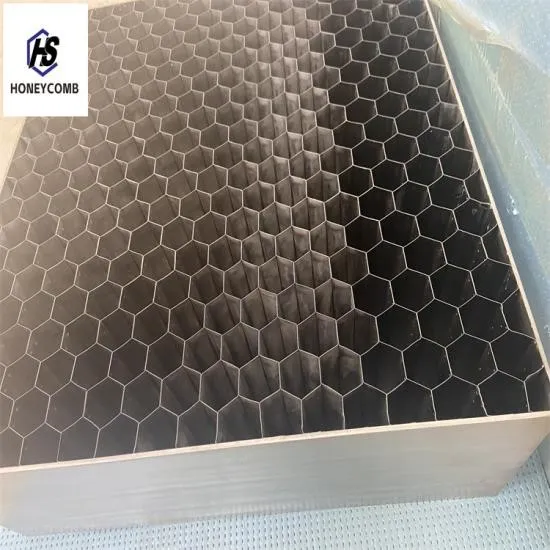

EMI honeycomb structures have emerged as a groundbreaking solution in the field of electromagnetic interference (EMI) shielding, addressing the widespread need for enhanced electronic device protection. The rapid growth of electronic components in consumer goods, automotive, aerospace, and medical sectors has intensified the demand for efficient EMI shielding solutions. EMI honeycombs stand out due to their unique combination of structural efficiency, lightweight design, and superior shielding performance.

In terms of practical application, the installation and integration of EMI honeycomb structures into existing systems are straightforward. They can be fitted into cables, enclosures, and various electronic assemblies without requiring significant redesigns. This ease of implementation makes them a cost-effective solution for companies looking to enhance their products' EMI shielding capabilities without incurring substantial development expenses. The superiority of EMI honeycomb structures is underscored by their durability and resilience. The materials used are typically resistant to corrosion, mechanical stress, and environmental factors, ensuring long-term performance and sustainability. This robustness translates to lower maintenance costs and prolonged lifespan of the devices they protect. Research and development in EMI honeycomb technologies continue to evolve, with ongoing studies focused on enhancing material properties, optimizing design configurations, and exploring new applications. As researchers make strides in nanotechnology and advanced materials, the potential for even greater improvements in EMI shielding capabilities becomes evident. The credibility and trustworthiness of EMI honeycomb solutions are reflected in their widespread adoption across various industries. Recognized for their innovative approach to EMI shielding, these structures have garnered endorsements from leading experts and industry authorities. The push towards more sustainable and efficient technologies further cements the relevance of EMI honeycombs in the future landscape of electronic design and engineering. In conclusion, the application of EMI honeycomb structures offers a viable path forward in the realm of EMI shielding. With proven expertise in design and material science, they deliver outstanding results in shielding effectiveness while maintaining critical considerations such as weight, thermal management, and durability. As electronic devices become more integral to daily life and advanced sectors, the role of sophisticated EMI shielding solutions like honeycomb structures will only grow in importance, ensuring reliable and uninterrupted device performance.

In terms of practical application, the installation and integration of EMI honeycomb structures into existing systems are straightforward. They can be fitted into cables, enclosures, and various electronic assemblies without requiring significant redesigns. This ease of implementation makes them a cost-effective solution for companies looking to enhance their products' EMI shielding capabilities without incurring substantial development expenses. The superiority of EMI honeycomb structures is underscored by their durability and resilience. The materials used are typically resistant to corrosion, mechanical stress, and environmental factors, ensuring long-term performance and sustainability. This robustness translates to lower maintenance costs and prolonged lifespan of the devices they protect. Research and development in EMI honeycomb technologies continue to evolve, with ongoing studies focused on enhancing material properties, optimizing design configurations, and exploring new applications. As researchers make strides in nanotechnology and advanced materials, the potential for even greater improvements in EMI shielding capabilities becomes evident. The credibility and trustworthiness of EMI honeycomb solutions are reflected in their widespread adoption across various industries. Recognized for their innovative approach to EMI shielding, these structures have garnered endorsements from leading experts and industry authorities. The push towards more sustainable and efficient technologies further cements the relevance of EMI honeycombs in the future landscape of electronic design and engineering. In conclusion, the application of EMI honeycomb structures offers a viable path forward in the realm of EMI shielding. With proven expertise in design and material science, they deliver outstanding results in shielding effectiveness while maintaining critical considerations such as weight, thermal management, and durability. As electronic devices become more integral to daily life and advanced sectors, the role of sophisticated EMI shielding solutions like honeycomb structures will only grow in importance, ensuring reliable and uninterrupted device performance.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025