- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 04, 2025 02:31

Back to list

maf straightener

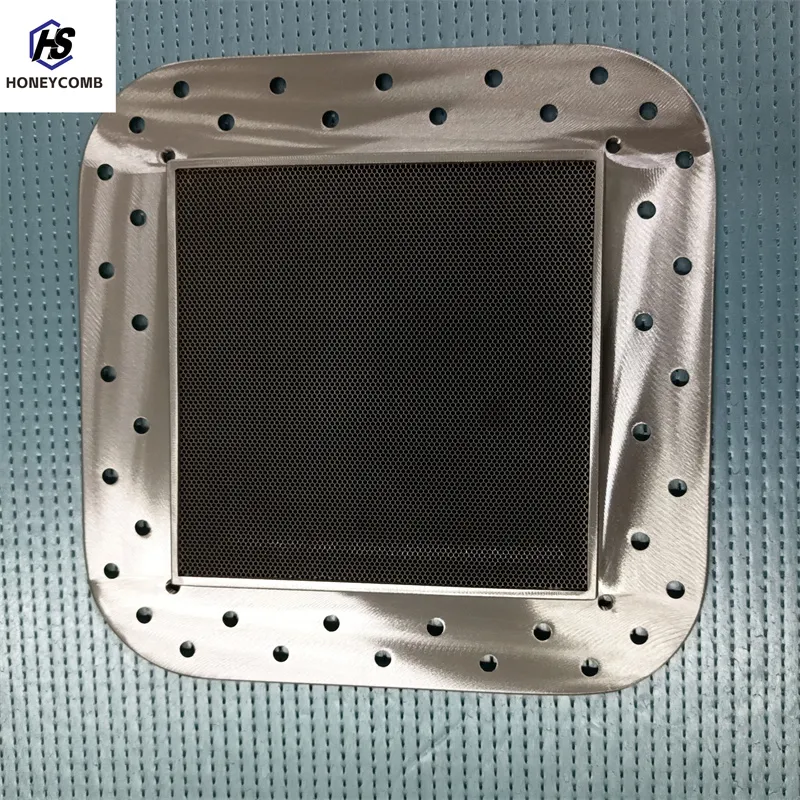

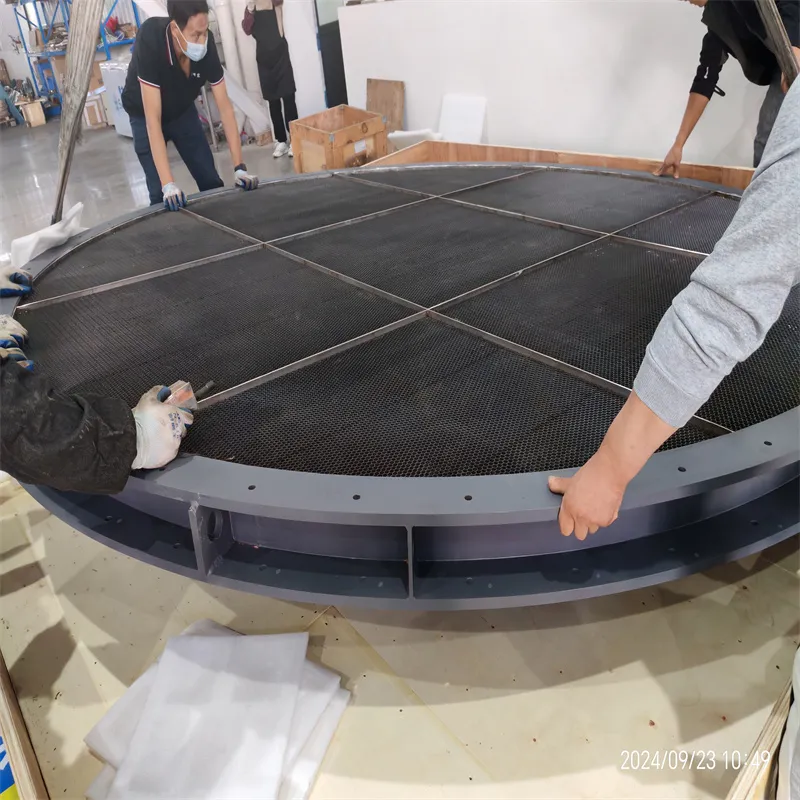

In the modern era of construction and high-tech engineering, the requirement for materials that offer an optimal balance of strength, weight, and cost efficiency is more pressing than ever. One such innovation reshaping various industries is the stainless steel honeycomb sandwich panel. This composite material is gaining ground due to its unique structural properties and multifaceted applications.

Engineering specialists advocate for these panels because they contribute to energy efficiency, a crucial factor in today's eco-conscious market. Buildings implemented with stainless steel honeycomb panels benefit from enhanced acoustic and thermal insulation. This results in energy savings and compliance with stringent building codes, proving their value in sustainable development projects. With global emphasis on reducing carbon footprints, such materials are not just a preference but a necessity. Industry leaders who have integrated these panels into their projects often report substantial improvements in the performance and safety of their constructions. The ability of these panels to absorb shock and vibrations makes them an outstanding choice for high-rise buildings and bridges, contributing to structural safety and comfort. Architects appreciate the versatility and aesthetic versatility, enabling them to design bold, innovative structures without compromising on safety or functionality. Beyond the technical attributes, the credibility of manufacturers plays an indisputable role in the widespread acceptance of stainless steel honeycomb sandwich panels. Leading manufacturers ensure compliance with international standards and rigorous quality checks, establishing trust and maintaining the highest level of customer satisfaction and credibility. When procurement decisions hinge on product trustworthiness, manufacturers’ reputation and adherence to quality standards cannot be overstated. In conclusion, the stainless steel honeycomb sandwich panel is more than just a product; it is a testament to advanced engineering marrying versatility, strength, and durability. For industries striving towards future-proofing their infrastructure, these panels offer a definitive answer to evolving market demands. As they continue to revolutionize the realms of architecture and engineering, stakeholders would do well to consider their integral application, capitalizing on both immediate and long-term benefits and reinforcing the pathway towards innovative and sustainable development.

Engineering specialists advocate for these panels because they contribute to energy efficiency, a crucial factor in today's eco-conscious market. Buildings implemented with stainless steel honeycomb panels benefit from enhanced acoustic and thermal insulation. This results in energy savings and compliance with stringent building codes, proving their value in sustainable development projects. With global emphasis on reducing carbon footprints, such materials are not just a preference but a necessity. Industry leaders who have integrated these panels into their projects often report substantial improvements in the performance and safety of their constructions. The ability of these panels to absorb shock and vibrations makes them an outstanding choice for high-rise buildings and bridges, contributing to structural safety and comfort. Architects appreciate the versatility and aesthetic versatility, enabling them to design bold, innovative structures without compromising on safety or functionality. Beyond the technical attributes, the credibility of manufacturers plays an indisputable role in the widespread acceptance of stainless steel honeycomb sandwich panels. Leading manufacturers ensure compliance with international standards and rigorous quality checks, establishing trust and maintaining the highest level of customer satisfaction and credibility. When procurement decisions hinge on product trustworthiness, manufacturers’ reputation and adherence to quality standards cannot be overstated. In conclusion, the stainless steel honeycomb sandwich panel is more than just a product; it is a testament to advanced engineering marrying versatility, strength, and durability. For industries striving towards future-proofing their infrastructure, these panels offer a definitive answer to evolving market demands. As they continue to revolutionize the realms of architecture and engineering, stakeholders would do well to consider their integral application, capitalizing on both immediate and long-term benefits and reinforcing the pathway towards innovative and sustainable development.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025