- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 07, 2025 01:03

Back to list

ईएमआई हनीकॉम्ब वेंट

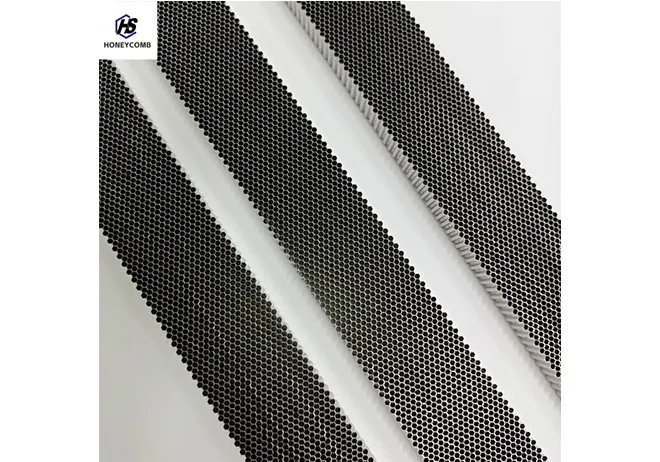

When selecting components for controlling electromagnetic interference (EMI) in rigorous environments, the need for effective, durable, and reliable solutions becomes paramount. This is where EMI honeycomb vents truly shine. By incorporating the quintessential design of honeycomb structures, these vents offer unparalleled advantages across several applications, ensuring uninterrupted functionality while maintaining high standards of compliance and performance.

Moreover, the integration of EMI honeycomb vents is seamless across various platforms, thanks to their customizable nature. Vents can be tailored in terms of size, shape, and mounting configurations to fit specific device requirements. Whether used in ventilation units of sophisticated radar systems or within intricate circuitry enclosures, these vents serve as a critical component in the integrity of electronic systems. To anyone knowledgeable in EMI reduction techniques, the adaptability and performance of honeycomb vents reinforce their status as a trusted solution. Their application reduces the need for continual maintenance or replacements, translating to long-term cost savings and enhanced operational reliability. Industry experts advocate their use due to their unrivaled efficiency in dissipating heat and facilitating cooling without compromising on EMI protection, a balance not easily achieved by alternative solutions. In real-world conditions, businesses that implement EMI honeycomb vents frequently report a marked improvement in device performance and reliability. Such firsthand accounts further verify their suitability, adding layers of credibility to claims about their effectiveness. For instance, aerospace applications have noticed reduced signal interference in avionics, leading to more accurate navigation and communication systems, thus substantiating the critical role these components play in high-stakes environments. With the continuous evolution of technology, incorporating EMI honeycomb vents into electronic devices ensures that safety, compliance, and performance benchmarks are constantly met. They remain a preferred choice for specialists aiming for sustained excellence in EMI management, echoing with authority and trustworthiness across the engineering landscape. Through continuous innovation and adherence to the highest standards of quality, EMI honeycomb vents maintain their elite status among EMI control solutions, offering holistic benefits to sophisticated industries globally.

Moreover, the integration of EMI honeycomb vents is seamless across various platforms, thanks to their customizable nature. Vents can be tailored in terms of size, shape, and mounting configurations to fit specific device requirements. Whether used in ventilation units of sophisticated radar systems or within intricate circuitry enclosures, these vents serve as a critical component in the integrity of electronic systems. To anyone knowledgeable in EMI reduction techniques, the adaptability and performance of honeycomb vents reinforce their status as a trusted solution. Their application reduces the need for continual maintenance or replacements, translating to long-term cost savings and enhanced operational reliability. Industry experts advocate their use due to their unrivaled efficiency in dissipating heat and facilitating cooling without compromising on EMI protection, a balance not easily achieved by alternative solutions. In real-world conditions, businesses that implement EMI honeycomb vents frequently report a marked improvement in device performance and reliability. Such firsthand accounts further verify their suitability, adding layers of credibility to claims about their effectiveness. For instance, aerospace applications have noticed reduced signal interference in avionics, leading to more accurate navigation and communication systems, thus substantiating the critical role these components play in high-stakes environments. With the continuous evolution of technology, incorporating EMI honeycomb vents into electronic devices ensures that safety, compliance, and performance benchmarks are constantly met. They remain a preferred choice for specialists aiming for sustained excellence in EMI management, echoing with authority and trustworthiness across the engineering landscape. Through continuous innovation and adherence to the highest standards of quality, EMI honeycomb vents maintain their elite status among EMI control solutions, offering holistic benefits to sophisticated industries globally.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025