- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 10, 2025 19:51

Back to list

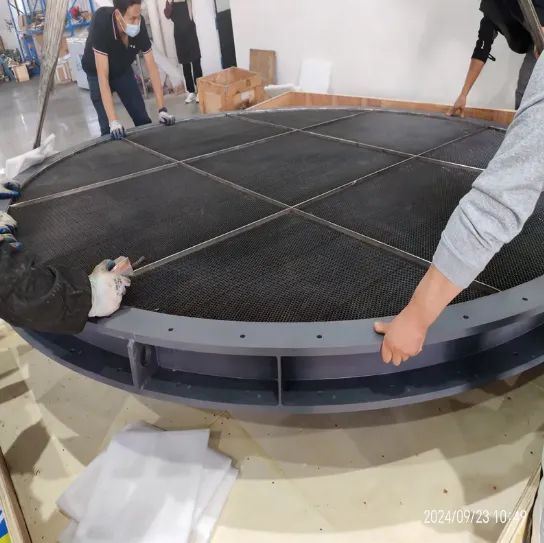

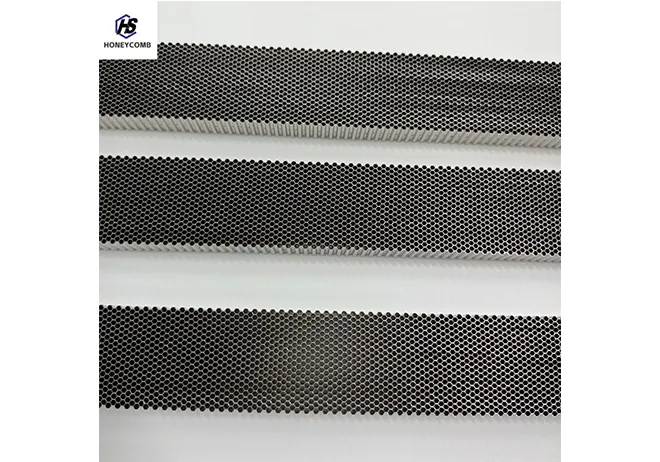

Honeycomb Waveguide Window/Panel

Industrial honeycombs are revolutionizing multiple sectors by providing innovative solutions that deliver superior strength, energy efficiency, and adaptability. These engineered structures, inspired by the natural geometry of bee honeycombs, offer unparalleled durability and lightweight characteristics, making them ideal for a multitude of applications.

Despite the numerous benefits, the production of industrial honeycombs requires a meticulous manufacturing process governed by industry standards. It involves layering sheets of the chosen material and forming them into the hexagonal pattern characteristic of honeycombs. This process demands precision and expertise to ensure that the final product meets the necessary quality and safety standards. Leading manufacturers invest in state-of-the-art technology and skilled personnel to produce top-notch industrial honeycombs. They often conduct rigorous testing and quality control, underscoring the importance of expertise and trustworthiness in this domain. Adherence to these processes ensures that the honeycombs can withstand the demanding environments of their respective applications. Investors and stakeholders in sectors that utilize industrial honeycombs should consider the credibility and track record of their suppliers. This due diligence will help in acquiring reliable products that maximize performance and longevity. Furthermore, continuous research and development in this field are paramount for discovering new materials and techniques that could enhance the properties of industrial honeycombs. The future of industrial honeycombs looks promising as industries constantly seek materials that meet the demands of modern engineering. Ongoing advancements in material science and manufacturing processes are likely to further expand their applications, offering even greater efficiency, sustainability, and performance. Therefore, staying informed about these developments is crucial for businesses aiming to leverage the full potential of industrial honeycombs in their operations. In conclusion, industrial honeycombs exemplify a perfect marriage of nature-inspired design and advanced engineering, offering endless possibilities for innovation across various sectors. Their unique combination of lightness, strength, and adaptability positions them as a pivotal component in the quest for sustainability and efficiency in industrial applications.

Despite the numerous benefits, the production of industrial honeycombs requires a meticulous manufacturing process governed by industry standards. It involves layering sheets of the chosen material and forming them into the hexagonal pattern characteristic of honeycombs. This process demands precision and expertise to ensure that the final product meets the necessary quality and safety standards. Leading manufacturers invest in state-of-the-art technology and skilled personnel to produce top-notch industrial honeycombs. They often conduct rigorous testing and quality control, underscoring the importance of expertise and trustworthiness in this domain. Adherence to these processes ensures that the honeycombs can withstand the demanding environments of their respective applications. Investors and stakeholders in sectors that utilize industrial honeycombs should consider the credibility and track record of their suppliers. This due diligence will help in acquiring reliable products that maximize performance and longevity. Furthermore, continuous research and development in this field are paramount for discovering new materials and techniques that could enhance the properties of industrial honeycombs. The future of industrial honeycombs looks promising as industries constantly seek materials that meet the demands of modern engineering. Ongoing advancements in material science and manufacturing processes are likely to further expand their applications, offering even greater efficiency, sustainability, and performance. Therefore, staying informed about these developments is crucial for businesses aiming to leverage the full potential of industrial honeycombs in their operations. In conclusion, industrial honeycombs exemplify a perfect marriage of nature-inspired design and advanced engineering, offering endless possibilities for innovation across various sectors. Their unique combination of lightness, strength, and adaptability positions them as a pivotal component in the quest for sustainability and efficiency in industrial applications.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025