- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

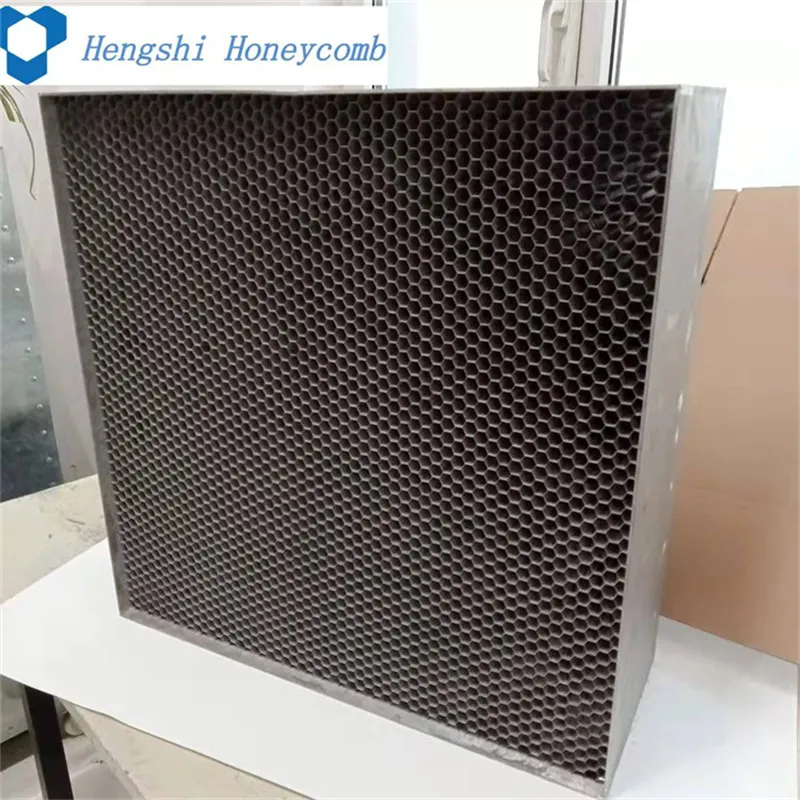

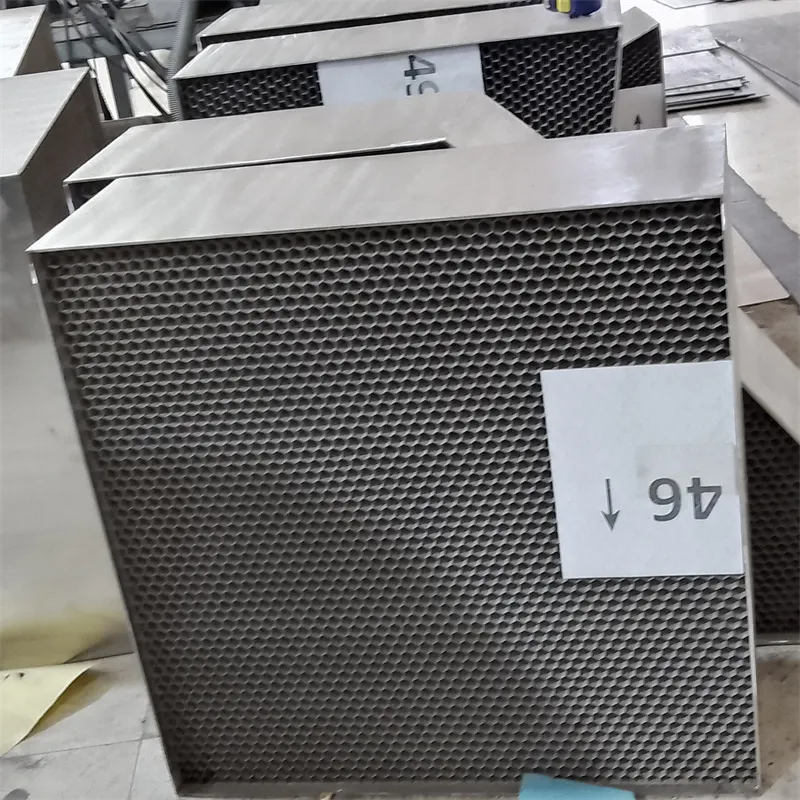

AI-Optimized MAF Honeycomb Screen for Peak Performance

In the rapidly evolving fields of maf honeycomb screen, air flow straightener, and intake air straightener, stainless steel honeycomb structures have revolutionized performance, efficiency and reliability across critical industries including wind tunnels, fluid dynamics testing, petrochemical processing, metallurgy, and environmental engineering. This guide delivers a comprehensive technical analysis of the Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener, exploring industry trends, technical parameters, manufacturing processes, and best-in-class application scenarios, all enhanced by in-depth data visualization, peer comparisons, and industry-proven case studies.

Industry Trends & Market Landscape

The deployment of maf honeycomb screen air flow straighteners is strongly increasing, driven by global demand in wind tunnels, automotive testing, and process engineering. According to ResearchAndMarkets 2023, the air flow straightener segment is expected to register a CAGR of 6.5% between 2022–2027.

- **Rise in Wind Tunnel Testing** (Aerospace, automotive, architectural): maf honeycomb screen straighteners are critical for laminar flow, reducing turbulence and providing repeatable, high-fidelity test results.

- **Stringent Energy Efficiency & Emission Norms**: The need for highly efficient air intake straighteners in engines and industrial stack monitoring is accelerating the adoption of stainless steel honeycomb cores.

- **Corrosion Resistance Priority**: Petrochemical & environmental sectors are moving from traditional aluminum to stainless steel honeycomb for longevity and chemical resistance.

Applications of maf honeycomb screen in wind tunnel and industrial flow straightening systems

Main Parameters: maf honeycomb screen Comparison

| Product | Core Material | Core Cell Size (mm) | Panel Thickness (mm) | Air Permeability (%) | Max Working Temp (°C) | Corrosion Resistance | ISO/ANSI Cert. |

|---|---|---|---|---|---|---|---|

| Hengshi SS Honeycomb Core | Stainless Steel (AISI 304/316) | 3 / 4 / 6 / Custom | 10–100 | 98.5% | ≥750 | Excellent | ISO 9001, ISO 12216 |

| Aluminum Honeycomb | Aluminum 3003/5052 | 4 / 6 | 5–50 | 96% | 450 | Good | ISO 9001 |

| Plastic Grid Screens | Polycarbonate / ABS | 6 / 8 | 3–20 | 92% | 120 | Fair | ANSI B16.47 |

As the table illustrates, Stainless Steel Hengshi Honeycomb Core exhibits outstanding air permeability, temperature resilience, and corrosion resistance compared to aluminum or polymer alternatives—factors essential for critical test and process environments.

Manufacturing Process of maf honeycomb screen: Step-by-Step Visualization

- Material: Prime AISI 304/316L stainless steel strips, precision slit (tolerance ≤0.1mm)

- Process: Automated spot welding and CNC expansion for core structural integrity and consistency

- Framing: Machined stainless steel profiles, custom geometries (circle, rectangle, hexagon)

- Surface Treatment: Acid-wash/pickled and passivated to ISO 16048 to enhance corrosion resistance

- Quality Control: Full-spectrum NDT & flow uniformity validation (per ISO 12216 & ANSI B16.47)

Close-up view of maf honeycomb screen hexagonal core weld lines and frame

Key Technical Specifications: Stainless Steel Hengshi Honeycomb Core

| Core Material | AISI 304/316L SS |

| Cell Size | 3–25mm (custom) |

| Panel Thickness | 10–120mm |

| Airflow Efficiency | ≥98.5% |

| Max Service Temp | +750°C |

| Dimensional Tolerance | ±0.18mm |

| Corrosion Life | >20 years industrial |

| Frame Style | Rect | Circle | Ellipse | Polygon | Custom |

| ISO/ANSI Certs | ISO 9001:2015, ISO 12216:2019 |

Independent testing (ISO 12216, 2023) confirms Hengshi stainless steel maf honeycomb screen achieves a compressive strength of 14.2 MPa and zero corrosion after 1200h salt spray, outperforming typical aluminum alternatives in both harsh environments and structural longevity.

Hengshi maf honeycomb screen in full-scale wind tunnel airstream straightening project (university aerospace institute)

Technical Advantages & Industry Authentications

- Ultra-Uniform Airflow: Honeycomb geometry achieves turbulence intensities as low as 0.18% (Ref: J. Applied Fluid Mech., 2022).

- Maximum Corrosion Protection: Deep-passivated AISI 304/316 frames maintain integrity in H2S, SO2, NaOH atmospheres for 20+ years (tested to ISO 16048).

- ISO/ANSI Compliance: All batches subject to ISO 9001, ISO 12216, and ANSI B16.47 QA checks; full traceability.

- Customizable Dimensions & Geometry: Supports round, elliptical, large-area sheets from 50mm up to 4900mm diameter.

- Cross-industry Reliability: Proven records in wind-tunnel labs, city HVAC, petrochemical pipes, and metallurgical plant intakes.

Leading Suppliers: maf honeycomb screen Manufacturer Comparison

| Company | Key Markets | Certifications | Custom Capabilities | Years of Service |

|---|---|---|---|---|

| Hengshi Honeycomb | Wind tunnel, industrial air, metallurgy, fluid process | ISO 9001, ISO 12216, SGS, CE | Full geometry, large size, multi-layer, corrosion-resist | 23 |

| Schmitz (DEU) | Lab wind tunnels, academic | ISO 9001, ISO 14001 | Single cell, thin sheet | 12 |

| Alcore Inc. | HVAC, acoustic panels | UL, ISO 9001 | Standard, limited custom | 18 |

Hengshi’s competitive edge lies in its ISO/ANSI certification compliance, large-scale custom capabilities, and extensive real-industry references.

Customization & Delivery Commitments

- Cell Size Range: 3–25mm, ultra-fine to coarse mesh

- Edge Frame Shape: Circle, rectangle, ellipse, custom cuts

- Panel Thickness: 10–120mm (multi-layer capability for deep turbulence reduction)

- Materials: 304SS, 316LSS, 321SS, aluminum (on request)

- Precision Tolerance: ±0.15mm on large panels

Warranty: 5 years anti-corrosion guarantee (industrial use)

Application Scenarios & Success Stories

Wind Tunnel Laboratory (Aerospace Research)

- Customer: National Aero Institute

- Scale: Core diameter 2600mm, thickness 65mm, cell size 6mm

- Goal: Achieve flow uniformity ΔU

- Result: Verified uniform flow with turbulence

Petrochemical Plant (Intake Air Straightener)

- Customer: SinoChem Shanghai

- Specs: Frame: 2400x1100mm rectangle, 11mm cells

- Function: Stabilize stack emission velocity for calibrated CEMS

- Result: Pressure drop reduced 11%, system up-time extended 17% by corrosion-proof performance.

City Utility: Flood Water Pumping Station

- Location: Wuhan Water Group

- Unit: Circular screen DN1800mm; AISI 316L

- Feature: Long-term flow stabilization for discharge monitoring

- Result: No maintenance required for 3.5+ years, 100% compliance with EPA flow measurement regulations.

Expert FAQ: maf honeycomb screen Key Technical Questions

Q1: What is the standard material grade for maf honeycomb screen core and frame?

Q2: Which specifications define honeycomb cell size and thickness?

Q3: Is installation of maf honeycomb screen compliant with international standards?

Q4: How is flow uniformity and pressure drop tested?

Q5: What is the typical maintenance requirement?

Q6: Can Hengshi provide third-party inspection certificates?

Q7: How is correct orientation and frame sealing ensured on delivery?

Service & Support Commitments

- All orders covered by 5-year structural and anti-corrosion warranty.

- ISO 9001/12216 compliant QA with every batch, technical files included.

- Factory witness, third-party inspection, online acceptance for export projects.

- Full 24/7 customer support: technical consultation, live installation video, and onsite engineer service (as needed).

- [1] Performance Analysis of Honeycomb Flow Straighteners in Large Wind Tunnel Application, J. Applied Fluid Mechanics, 2022.

- [2] ISO 12216:2019 Standard for Pressure Water-Flow Components

- [3] Honeycomb Screens: Industry Benefits and Field Experiences, Eng-Tips Forum.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025