- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 11:20

Back to list

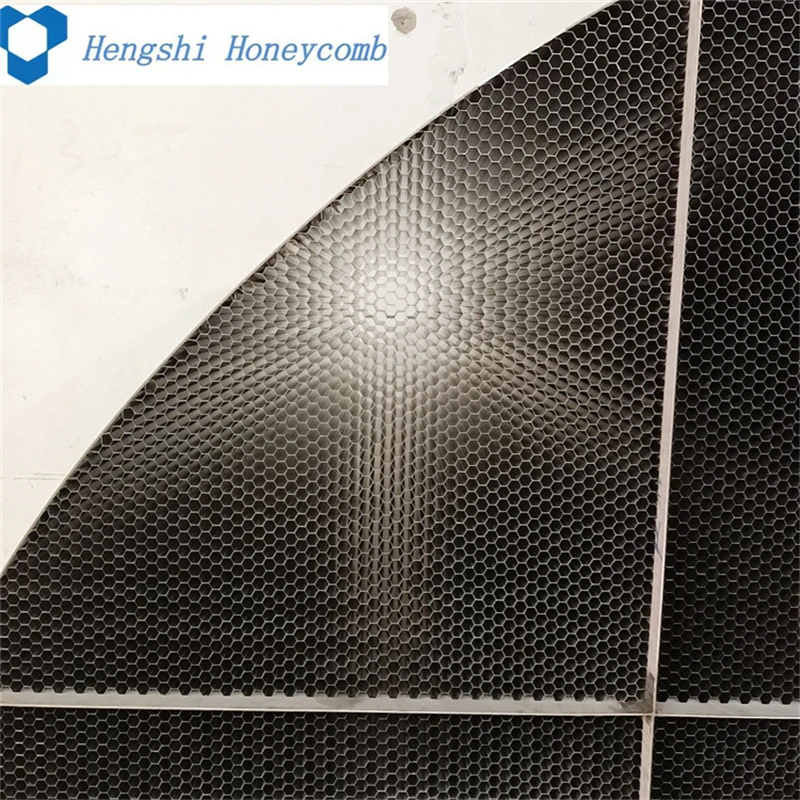

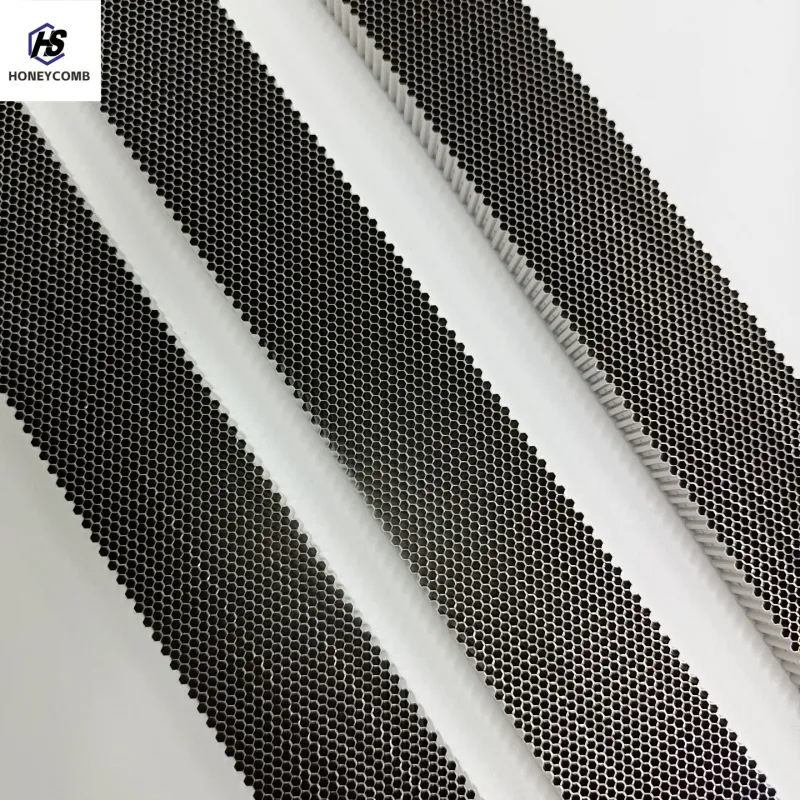

alloy honeycomb sheet

Alloy honeycomb sheets stand as a revolutionary innovation in the field of lightweight materials with versatile applications, from aerospace engineering to architectural designs. Their unique structure offers significant advantages that are drawing attention from industries that demand a balance between strength and weight efficiency.

From a perspective of authority, the development and continuous enhancement of alloy honeycomb sheets are supported by extensive research conducted by leading institutions and material scientists. Innovations in alloy compositions have resulted in sheets that are not only more robust but also resistant to corrosion and wear, ensuring longevity and reliability of the structures they are part of. These advancements are made possible through collaborations between academia and industry, where theoretical knowledge meets practical application. Trust in alloy honeycomb sheets comes from their proven track record in multiple high-stakes environments. Marine engineers utilize these materials for ship partitions because of their excellent moisture resistance and acoustic properties. Similarly, the automotive sector is harnessing their strength-to-weight ratio to design vehicles that exceed safety standards while promoting fuel efficiency. Consumers and industries alike can rely on alloy honeycomb sheets, given the rigorous testing and quality control measures they undergo before reaching the market. In conclusion, the alloy honeycomb sheet is not just a product but a breakthrough in material science. Combining innovative engineering design with cutting-edge alloys, these sheets offer unparalleled benefits that continue to transform various industries. They represent a forward-thinking approach to solving complex engineering challenges with efficiency, sustainability, and unparalleled reliability.

From a perspective of authority, the development and continuous enhancement of alloy honeycomb sheets are supported by extensive research conducted by leading institutions and material scientists. Innovations in alloy compositions have resulted in sheets that are not only more robust but also resistant to corrosion and wear, ensuring longevity and reliability of the structures they are part of. These advancements are made possible through collaborations between academia and industry, where theoretical knowledge meets practical application. Trust in alloy honeycomb sheets comes from their proven track record in multiple high-stakes environments. Marine engineers utilize these materials for ship partitions because of their excellent moisture resistance and acoustic properties. Similarly, the automotive sector is harnessing their strength-to-weight ratio to design vehicles that exceed safety standards while promoting fuel efficiency. Consumers and industries alike can rely on alloy honeycomb sheets, given the rigorous testing and quality control measures they undergo before reaching the market. In conclusion, the alloy honeycomb sheet is not just a product but a breakthrough in material science. Combining innovative engineering design with cutting-edge alloys, these sheets offer unparalleled benefits that continue to transform various industries. They represent a forward-thinking approach to solving complex engineering challenges with efficiency, sustainability, and unparalleled reliability.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025