- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 03, 2025 05:03

Back to list

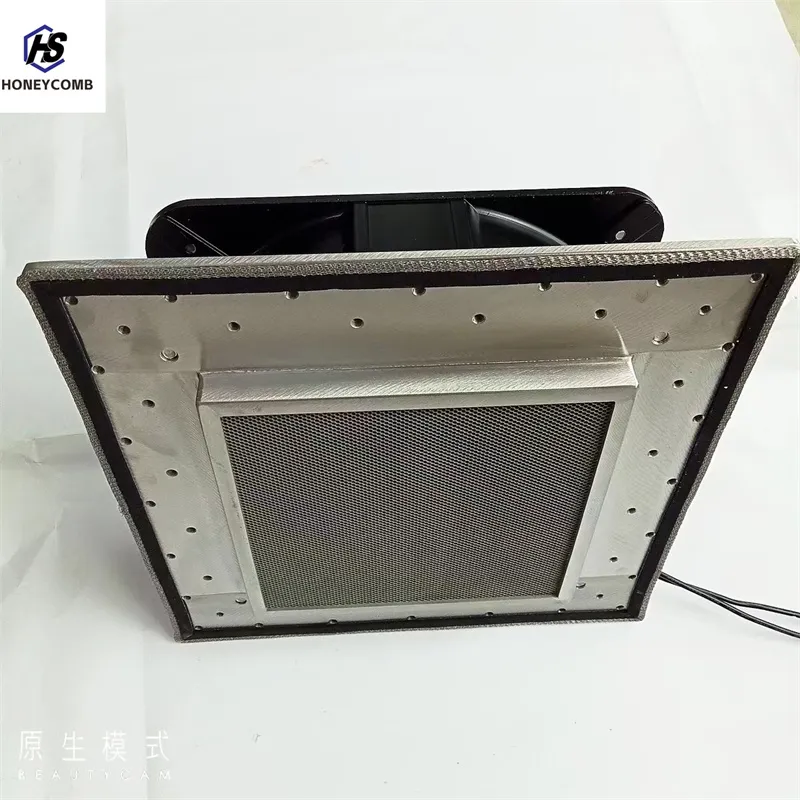

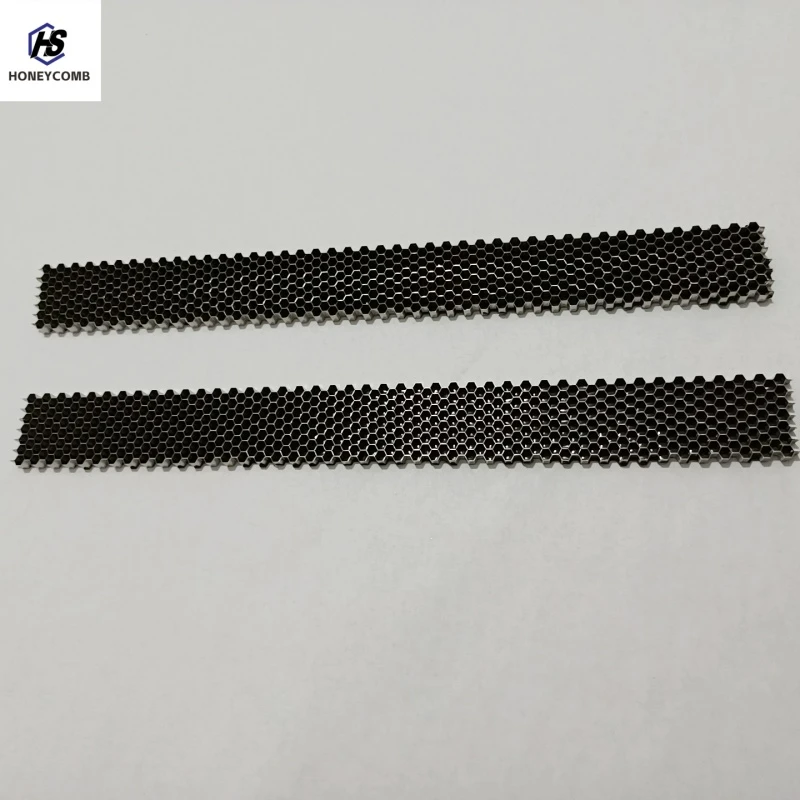

Hengshi Honeycomb Stainless Steel/Hastelloy Honeycomb Seals Strips Gas Seal Strips

Stainless steel is a material that has long been revered for its strength and durability, particularly in fields where the reliability of the material is pivotal, such as in the creation of firearms and ammunition. The bikakekärna, or core, in stainless steel is an innovative leap in the manufacture of ammunition, offering a variety of benefits that make it particularly suitable for the modern demands of precision and reliability.

From a manufacturing perspective, using stainless steel involves cutting-edge techniques that highlight advancements in metallurgical science. The precision engineering required to produce a stainless steel bikakekärna involves specific processes that ensure each core is made to exact standards. This commitment to quality is reflected in the performance of the final product, giving users confidence in their equipment. Moreover, users express high levels of satisfaction with stainless steel cores due to the minimal maintenance required. Unlike softer metals, which can deform or require frequent cleaning and care, stainless steel's robust nature means it stays operationally ready with less frequent intervention. This reliability translates into significant time savings and ensures that users can focus on their objectives without undue concern over equipment performance. Trust in the bikakekärna in stainless steel is further bolstered by feedback from both military and civilian applications where precision, performance, and reliability are non-negotiable. Testimonials from professionals underscore the core's utility in enhancing firing capabilities and its role in modern arms innovation. In summary, the bikakekärna in stainless steel is setting new standards in ammunition production, melding durability with environmentally-conscious manufacturing and expert engineering. Its adoption signifies a shift towards more sustainable production without compromising the critical performance aspects demanded by professionals around the globe. As a result, this advancement is not just meeting current demands but is leading towards the future of responsible and reliable ammunition technology.

From a manufacturing perspective, using stainless steel involves cutting-edge techniques that highlight advancements in metallurgical science. The precision engineering required to produce a stainless steel bikakekärna involves specific processes that ensure each core is made to exact standards. This commitment to quality is reflected in the performance of the final product, giving users confidence in their equipment. Moreover, users express high levels of satisfaction with stainless steel cores due to the minimal maintenance required. Unlike softer metals, which can deform or require frequent cleaning and care, stainless steel's robust nature means it stays operationally ready with less frequent intervention. This reliability translates into significant time savings and ensures that users can focus on their objectives without undue concern over equipment performance. Trust in the bikakekärna in stainless steel is further bolstered by feedback from both military and civilian applications where precision, performance, and reliability are non-negotiable. Testimonials from professionals underscore the core's utility in enhancing firing capabilities and its role in modern arms innovation. In summary, the bikakekärna in stainless steel is setting new standards in ammunition production, melding durability with environmentally-conscious manufacturing and expert engineering. Its adoption signifies a shift towards more sustainable production without compromising the critical performance aspects demanded by professionals around the globe. As a result, this advancement is not just meeting current demands but is leading towards the future of responsible and reliable ammunition technology.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025