- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 16, 2025 16:12

Back to list

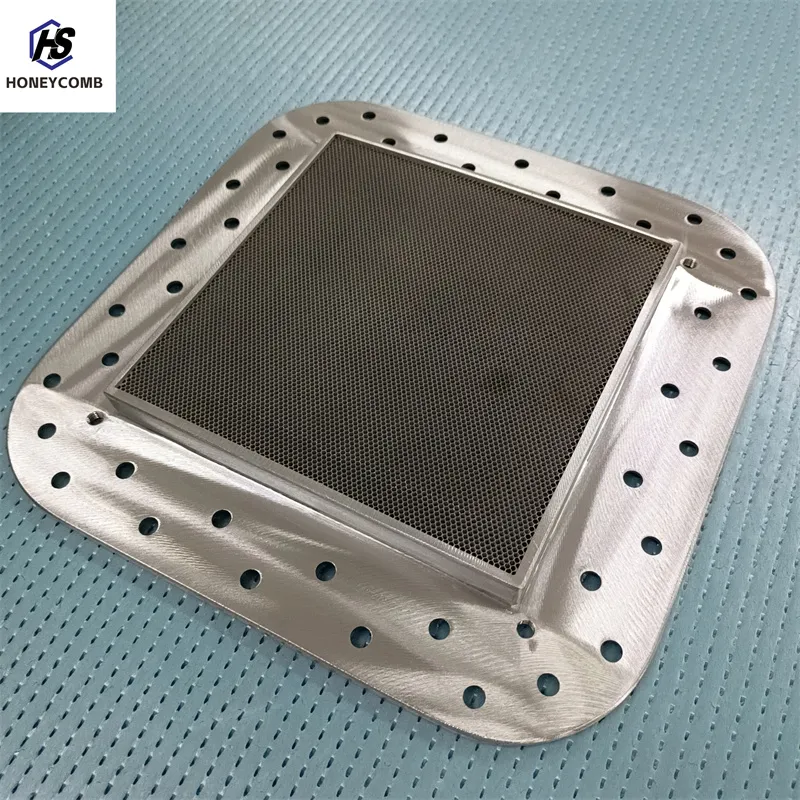

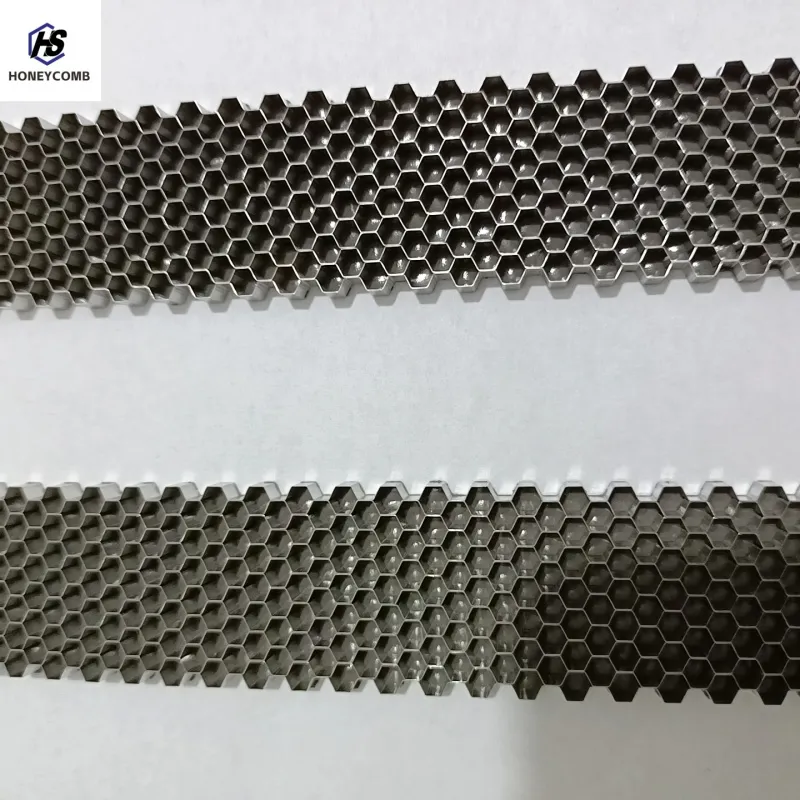

maf honeycomb screen

Stainless steel honeycomb panels have become a revolutionary solution in various industries, providing an exquisite combination of lightweight properties, strength, and resistance to corrosion. Initially inspired by the natural structure of honeycombs, these panels have transcended their conventional use, offering enormous benefits across multiple domains.

The authoritative voice within the community highlights safety and performance standards that underscore the trustworthiness of stainless steel honeycomb panels. Comprising industry experts who have rigorously tested these materials under diverse scenarios, they have established benchmarks that ensure reliability. One such standard involves extensive testing against high impact forces, where the material consistently demonstrated remarkable resilience. Indeed, the trust placed in these materials extends beyond product specifications to encompass the manufacturing process itself. Leading manufacturers adhere to stringent quality assurance protocols to maintain consistency across batches, employing advanced technology and methodologies that prevent defects and ensure durability. This meticulous attention to detail builds confidence among architects, engineers, and end-users alike, reinforcing the material's reputation for reliability. Customer testimonials further cement the credibility of stainless steel honeycomb panels. A construction manager recounted his experience using these panels in a high-rise project, highlighting their ease of installation and maintenance. He emphasized not only their performance under stress but also the aesthetic value they added to the structure, addressing both functional and design requirements seamlessly. His account reaffirms the panels' utility in modern construction. Stainless steel honeycomb panels exemplify a perfect synergy of design, strength, and sustainability. Their adoption across various sectors aligns with current trends emphasizing reduced carbon footprints and increased energy efficiency. By continuing to innovate and adapt these materials to new applications, the industry responds to evolving challenges and consumer demands, paving the way for future advancements.

The authoritative voice within the community highlights safety and performance standards that underscore the trustworthiness of stainless steel honeycomb panels. Comprising industry experts who have rigorously tested these materials under diverse scenarios, they have established benchmarks that ensure reliability. One such standard involves extensive testing against high impact forces, where the material consistently demonstrated remarkable resilience. Indeed, the trust placed in these materials extends beyond product specifications to encompass the manufacturing process itself. Leading manufacturers adhere to stringent quality assurance protocols to maintain consistency across batches, employing advanced technology and methodologies that prevent defects and ensure durability. This meticulous attention to detail builds confidence among architects, engineers, and end-users alike, reinforcing the material's reputation for reliability. Customer testimonials further cement the credibility of stainless steel honeycomb panels. A construction manager recounted his experience using these panels in a high-rise project, highlighting their ease of installation and maintenance. He emphasized not only their performance under stress but also the aesthetic value they added to the structure, addressing both functional and design requirements seamlessly. His account reaffirms the panels' utility in modern construction. Stainless steel honeycomb panels exemplify a perfect synergy of design, strength, and sustainability. Their adoption across various sectors aligns with current trends emphasizing reduced carbon footprints and increased energy efficiency. By continuing to innovate and adapt these materials to new applications, the industry responds to evolving challenges and consumer demands, paving the way for future advancements.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025