- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 07, 2025 01:20

Back to list

blindagem de filtros de ventilador em favo de mel

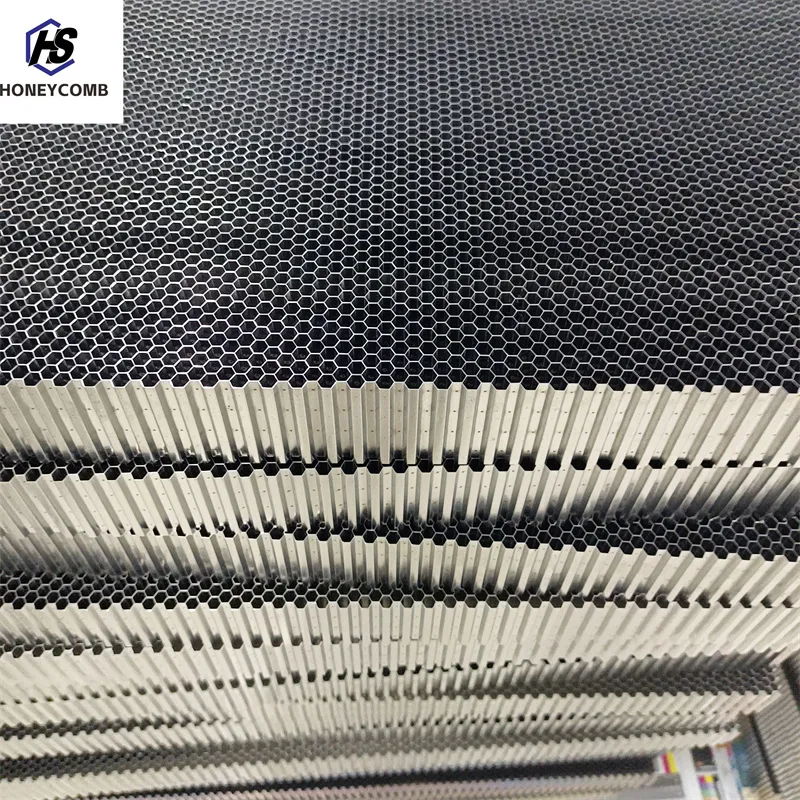

The honeycomb fan filter shielding, a product well-celebrated in industries requiring optimal airflow management and enhanced equipment longevity, stands as a testament to modern engineering marvels. This component's unique design not only provides unparalleled protection to sensitive machinery but also exemplifies how intricate engineering can meet practical solutions for everyday industrial challenges.

Customers who have implemented honeycomb fan filter shielding often report not only improved equipment reliability but also extended service life for their machinery. This attribute is crucial in industries where machine downtime can lead to substantial financial losses. For example, in data centers, maintaining optimal equipment performance is key. Here, honeycomb fan filter shielding ensures servers remain cool, operational, and less prone to the debilitating effects of dust and heat exposure. The authority that honeycomb fan filter shielding commands in engineering circles is further validated by endorsements from leading industry bodies and certifications that attest to its quality and effectiveness. Products are subjected to rigorous testing standards that mimic harsh operational environments, ensuring that they perform consistently and reliably under pressure. Trust in honeycomb fan filter shielding is not just built on technical specifications but also on the tangible operational improvements users experience. Feedback loops from field applications to design enhancements ensure that each iteration of these filters surpasses the last in quality and efficiency. Moreover, lifecycle analyses repeatedly show a strong return on investment, which reinforces customer trust and confidence in choosing this solution. In conclusion, honeycomb fan filter shielding represents a pinnacle of innovative engineering, combining nature-inspired designs with cutting-edge technology to deliver unmatched results. Its role in enhancing equipment performance while safeguarding vital components makes it an indispensable asset in various high-stakes industries. Through ongoing research and improvements, honeycomb fan filter shielding continues to build upon its legacy, proving it to be an invaluable tool for those seeking to optimize operational efficiency and ensure the longevity of their technological investments.

Customers who have implemented honeycomb fan filter shielding often report not only improved equipment reliability but also extended service life for their machinery. This attribute is crucial in industries where machine downtime can lead to substantial financial losses. For example, in data centers, maintaining optimal equipment performance is key. Here, honeycomb fan filter shielding ensures servers remain cool, operational, and less prone to the debilitating effects of dust and heat exposure. The authority that honeycomb fan filter shielding commands in engineering circles is further validated by endorsements from leading industry bodies and certifications that attest to its quality and effectiveness. Products are subjected to rigorous testing standards that mimic harsh operational environments, ensuring that they perform consistently and reliably under pressure. Trust in honeycomb fan filter shielding is not just built on technical specifications but also on the tangible operational improvements users experience. Feedback loops from field applications to design enhancements ensure that each iteration of these filters surpasses the last in quality and efficiency. Moreover, lifecycle analyses repeatedly show a strong return on investment, which reinforces customer trust and confidence in choosing this solution. In conclusion, honeycomb fan filter shielding represents a pinnacle of innovative engineering, combining nature-inspired designs with cutting-edge technology to deliver unmatched results. Its role in enhancing equipment performance while safeguarding vital components makes it an indispensable asset in various high-stakes industries. Through ongoing research and improvements, honeycomb fan filter shielding continues to build upon its legacy, proving it to be an invaluable tool for those seeking to optimize operational efficiency and ensure the longevity of their technological investments.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025