- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 11:59

Back to list

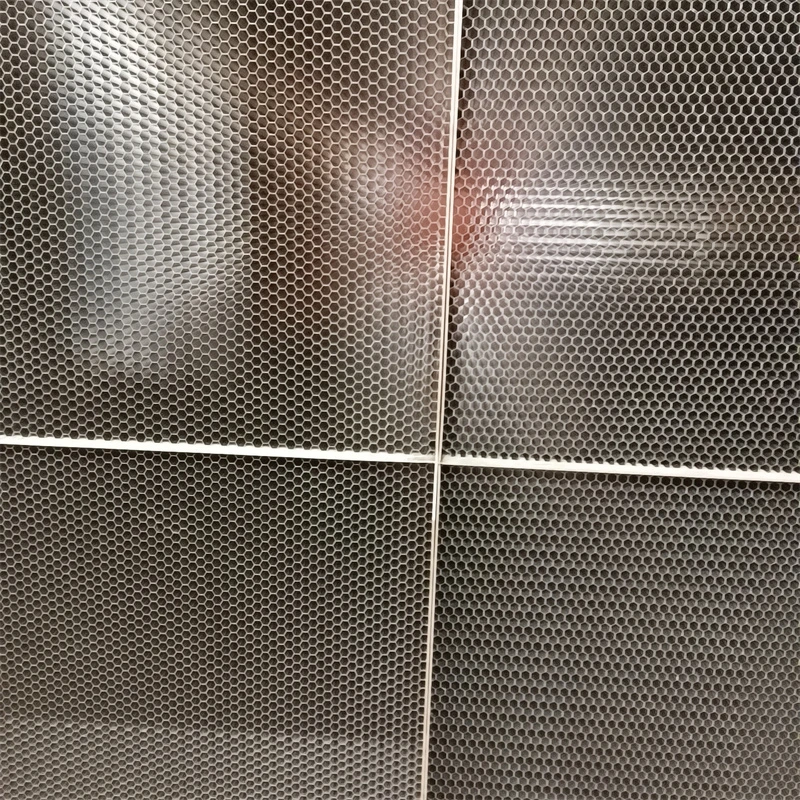

cell aluminium honeycomb

Cell aluminium honeycomb panels are revolutionizing industries ranging from aerospace to architectural design, providing an unparalleled combination of strength, flexibility, and lightweight efficiency. This cutting-edge material, characterized by its unique honeycomb structure, offers numerous benefits that make it an indispensable tool for modern engineering and construction projects.

Through years of documented research and first-hand case studies, it is evident that the use of aluminium honeycomb panels leads to a reduction in maintenance costs as well. Their resilience against harsh environmental conditions—such as corrosion and moisture—extends the lifespan of structures and machinery. This reliability underpins the trust industries place in aluminium honeycomb, reflecting their enduring commitment to quality and efficiency. From an expert's perspective, investing in cell aluminium honeycomb technology is a strategic decision towards future-proofing operations. It fosters sustainability, supports innovation, and meets the rigorous standards set by various industrial applications. The consistency with which aluminium honeycomb panels deliver performance and reliability underscores their status as a preferred material for top engineers and architects worldwide. For consumers and professionals looking to enhance their projects with advanced materials, turning to reputable suppliers who specialize in aluminium honeycomb panels is crucial. Ensuring product authenticity and quality guarantees that projects will benefit from the full range of advantages offered by this remarkable innovation. Engage with suppliers who possess deep industry knowledge and offer comprehensive after-sales support to leverage the full potential of modern material science. In conclusion, the widespread adoption of cell aluminium honeycomb panels marks a significant advancement in material technology. Whether the goal is to construct an iconic skyscraper, design a fuel-efficient vehicle, or improve aeronautical performance, aluminium honeycomb materials offer a robust, versatile, and long-lasting solution. By understanding their capabilities and leveraging their unique properties, industries can achieve new heights of efficiency and innovation.

Through years of documented research and first-hand case studies, it is evident that the use of aluminium honeycomb panels leads to a reduction in maintenance costs as well. Their resilience against harsh environmental conditions—such as corrosion and moisture—extends the lifespan of structures and machinery. This reliability underpins the trust industries place in aluminium honeycomb, reflecting their enduring commitment to quality and efficiency. From an expert's perspective, investing in cell aluminium honeycomb technology is a strategic decision towards future-proofing operations. It fosters sustainability, supports innovation, and meets the rigorous standards set by various industrial applications. The consistency with which aluminium honeycomb panels deliver performance and reliability underscores their status as a preferred material for top engineers and architects worldwide. For consumers and professionals looking to enhance their projects with advanced materials, turning to reputable suppliers who specialize in aluminium honeycomb panels is crucial. Ensuring product authenticity and quality guarantees that projects will benefit from the full range of advantages offered by this remarkable innovation. Engage with suppliers who possess deep industry knowledge and offer comprehensive after-sales support to leverage the full potential of modern material science. In conclusion, the widespread adoption of cell aluminium honeycomb panels marks a significant advancement in material technology. Whether the goal is to construct an iconic skyscraper, design a fuel-efficient vehicle, or improve aeronautical performance, aluminium honeycomb materials offer a robust, versatile, and long-lasting solution. By understanding their capabilities and leveraging their unique properties, industries can achieve new heights of efficiency and innovation.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025