- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 12, 2025 19:40

Back to list

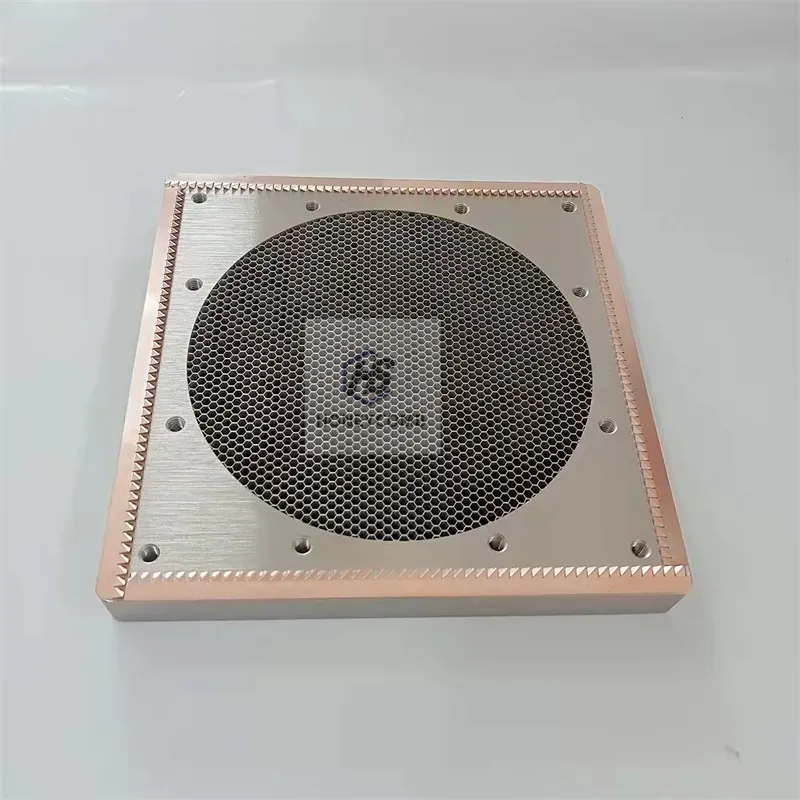

chapa metálica em favo de mel

The realm of honeycomb metal sheets is a fascinating one, combining the qualities of lightweight construction with robust mechanical properties. These sheets are named after their unique structure, which mimics the natural honeycomb, renowned for its incredible balance of strength and lightness. This architectural marvel, long admired in nature, is now a cornerstone in advanced manufacturing fields.

From an expertise standpoint, working with honeycomb metal sheets requires a deep understanding of their mechanical properties and how these can be optimized for specific applications. Engineers must consider factors such as the choice of material (aluminum is commonly used due to its light weight and corrosion resistance), cell size, and the thickness of the face sheets to tailor the composite to the intended use. The customization possibilities are virtually limitless, allowing for bespoke solutions that align precisely with the performance needs of the project. With regard to authoritativeness, the application of honeycomb metal sheets is backed by extensive research and development. Studies have demonstrated their superior performance characteristics in real-world scenarios, reinforcing their status as a trusted solution for demanding environments. Manufacturers often collaborate with academic institutions to advance the technology, ensuring that innovations in honeycomb design and fabrication are underpinned by rigorous scientific research. Concerning trustworthiness, companies specializing in honeycomb metal sheet production adhere to rigorous quality control standards, ensuring that each product meets the specifications required for its intended industrial use. Certification processes, often guided by international standards, regulate the manufacture and testing of these materials, providing an additional layer of confidence for consumers. In summary, honeycomb metal sheets represent a remarkable convergence of natural inspiration and technological innovation. Their unique structure offers a superior solution to the challenges of weight, strength, and material efficiency, establishing them as an indispensable resource across multiple high-tech industries. Experts, recognizing their potential, continuously explore new applications, while rigorous standards ensure reliability and performance. Through this blend of experience, expertise, authoritativeness, and trustworthiness, honeycomb metal sheets marshal a future where efficiency and strength go hand in hand.

From an expertise standpoint, working with honeycomb metal sheets requires a deep understanding of their mechanical properties and how these can be optimized for specific applications. Engineers must consider factors such as the choice of material (aluminum is commonly used due to its light weight and corrosion resistance), cell size, and the thickness of the face sheets to tailor the composite to the intended use. The customization possibilities are virtually limitless, allowing for bespoke solutions that align precisely with the performance needs of the project. With regard to authoritativeness, the application of honeycomb metal sheets is backed by extensive research and development. Studies have demonstrated their superior performance characteristics in real-world scenarios, reinforcing their status as a trusted solution for demanding environments. Manufacturers often collaborate with academic institutions to advance the technology, ensuring that innovations in honeycomb design and fabrication are underpinned by rigorous scientific research. Concerning trustworthiness, companies specializing in honeycomb metal sheet production adhere to rigorous quality control standards, ensuring that each product meets the specifications required for its intended industrial use. Certification processes, often guided by international standards, regulate the manufacture and testing of these materials, providing an additional layer of confidence for consumers. In summary, honeycomb metal sheets represent a remarkable convergence of natural inspiration and technological innovation. Their unique structure offers a superior solution to the challenges of weight, strength, and material efficiency, establishing them as an indispensable resource across multiple high-tech industries. Experts, recognizing their potential, continuously explore new applications, while rigorous standards ensure reliability and performance. Through this blend of experience, expertise, authoritativeness, and trustworthiness, honeycomb metal sheets marshal a future where efficiency and strength go hand in hand.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025