- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Cheap Steel Honeycomb Panels Manufacturer – High Quality, Low Cost Solutions

- Introduction to Cheap Steel Honeycomb Panels Manufacturer and Industry Overview

- Technical Advantages of Steel Honeycomb Mesh

- Manufacturing Process and Quality Control

- Manufacturer Comparison: Price, Quality, and Performance

- Customization Solutions for Diverse Industrial Applications

- Application Case Studies and Industry Insights

- Conclusion: Choosing the Right Cheap Steel Honeycomb Panels Manufacturer

(cheap steel honeycomb panels manufacturer)

Introduction to the Cheap Steel Honeycomb Panels Manufacturer Industry

Steel honeycomb panels have revolutionized structural solutions across a range of industries, delivering unmatched strength-to-weight ratios and advanced durability. The emergence of cheap steel honeycomb panels manufacturer

s has made these high-tech products accessible to a broader client base, driving innovation in applications ranging from architectural cladding to defense systems. As the need for lightweight, high-strength materials grows globally, the steel honeycomb market is projected to reach USD 2.5 billion by 2027, expanding at a robust CAGR of 6.8%, according to Grand View Research.

Key related products, such as stainless steel honeycomb mesh and specialized vent panels, have also seen surging demand as manufacturers offer cost-effective solutions without sacrificing quality. Top-tier suppliers in this domain compete not only on price but on engineering expertise, customization capacity, and compliance with international performance standards. The following analysis delves into technical advances, comparative data, and real-world use cases to aid decision-makers in selecting the ideal honeycomb panel partner.

Technical Advantages of Steel Honeycomb Mesh

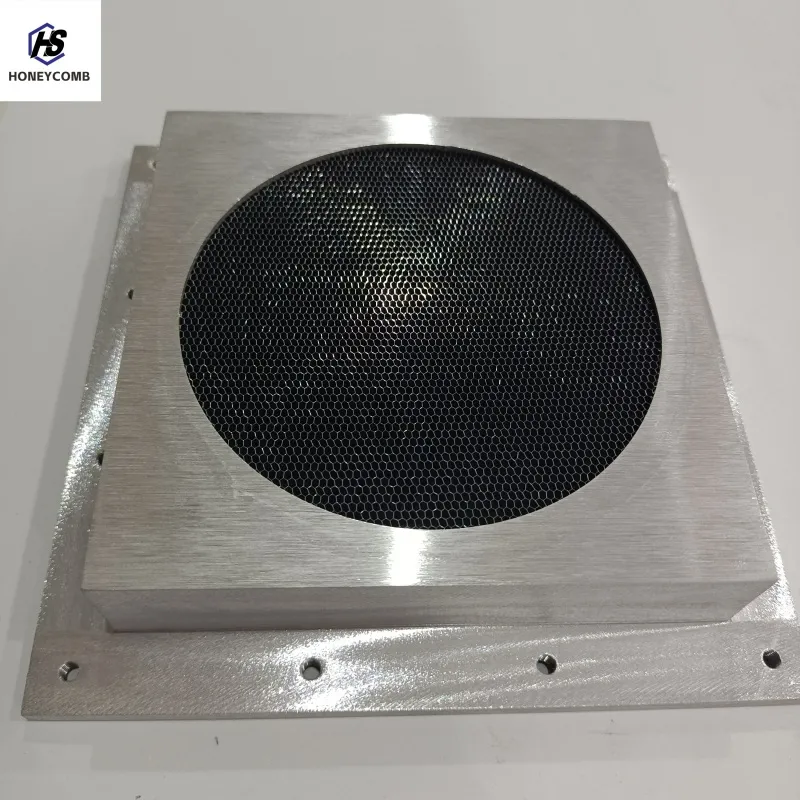

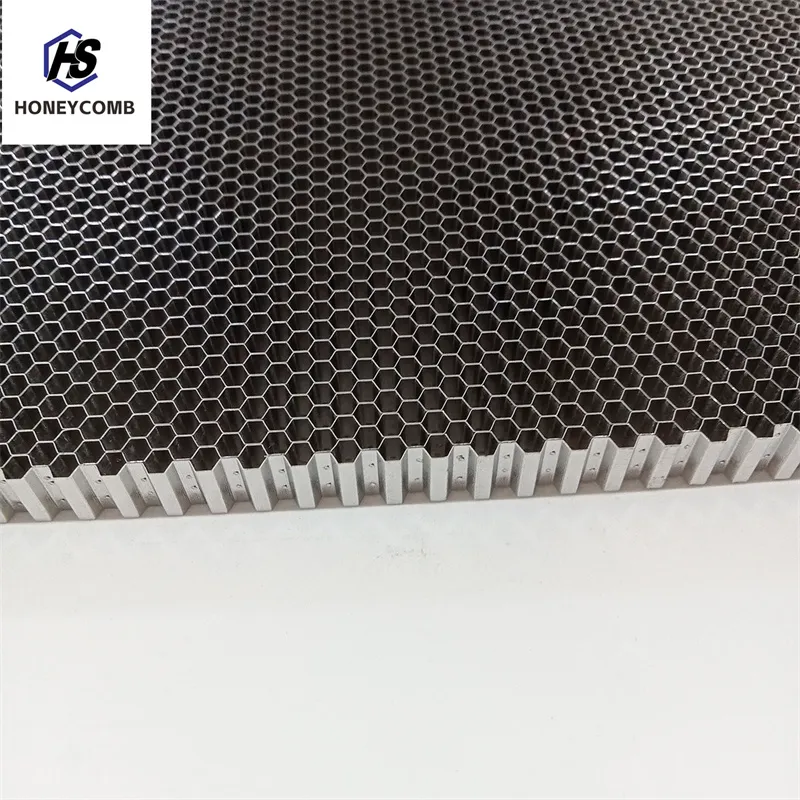

Steel honeycomb mesh features an innovative core structure, reminiscent of natural honeycomb, providing exceptional structural efficiency. The core's hexagonal geometry bridges the gap between high compressive strength and minimal material usage, achieving weight reductions of up to 60% over conventional solid panels. Structurally, these panels can withstand distributed loads of over 2000 N/m² while maintaining flatness and rigidity. Compared to polymeric materials, steel's inherent fire resistance, electromagnetic shielding, and thermal tolerance set it apart for safety-critical environments.

State-of-the-art manufacturers deploy laser welding, precision forming, and advanced surface treatments (e.g., epoxy coating, anodizing), resulting in panels that are highly corrosion-resistant and maintain mechanical integrity after decades of exposure. For industries such as aerospace and railways, where every kilogram counts, the panel’s density (typically 1.8–2.9 kg/m²) is a game-changer. Stainless steel honeycomb mesh includes grade selections such as SS304, SS316, and custom alloys, ensuring compatibility with hostile or hygiene-critical environments like cleanrooms and laboratories.

Manufacturing Process and Quality Control

Manufacturing reliable steel honeycomb panels is a multi-stage operation, tightly controlled to deliver consistent parameters and long-term reliability. The process usually entails the following phases: core preparation (expansion and gluing of strips), face-sheet bonding (high-temperature lamination or resistance welding), edge closure, and surface finishing. Quality benchmarks demand a surface flatness of under ±0.2 mm/m and bond strengths exceeding 5 MPa after environmental cycling.

A leading cheap stainless steel honeycomb mesh manufacturer invests in automated press lines, in-line vision inspection, and non-destructive testing (NDT) systems. These ensure that each panel is free of voids, delamination, and unbonded zones. Environmental compliance (RoHS, REACH), traceability (lot-level barcode tracking), and certificates such as ISO9001/AS9100 are now industry prerequisites. Only manufacturers embracing advanced robotic welding and in-process controls can consistently offer cheap yet robust panels suitable for the toughest use cases.

Manufacturer Comparison: Price, Quality, and Performance

Selecting the right supplier involves balancing cost, performance, and capacity for customization. The table below summarizes the offerings of three leading honeycomb panel manufacturers based on publicly available data and industrial benchmarks:

| Manufacturer | Panel Density (kg/m²) | Compressive Strength (N/m²) | Standard Panel Price (USD/m²) | Surface Finish Options | Lead Time (days) | Compliance & Certifications |

|---|---|---|---|---|---|---|

| Honeycomb Tech Solutions | 2.0 | 2100 | 32–36 | SS304, Powder coat, PVDF | 12–15 | ISO9001, RoHS, EN45545 |

| SteelCore Panels Inc. | 2.5 | 2300 | 28–31 | SS316, Anodizing, Custom dye | 10–13 | AS9100, REACH, UL |

| Armored Hive Manufacturing | 1.9 | 1850 | 26–29 | SS430, Mill finish | 15–18 | ISO14001, FireRated, CE |

The above data illustrates that even among low-cost manufacturers, there are significant differences in density, compressive strength, finish range, and compliance. SteelCore Panels Inc., for example, offers the best performance-to-price ratio for customized solutions and premium alloy options, whereas Armored Hive specializes in bulk, general-purpose panels for rapid deployment.

Customization Solutions for Diverse Industrial Applications

Leading honeycomb panel suppliers provide versatile customization to address unique structural, thermal, and acoustic specifications. Typical custom services include:

- Dimensions: Panel sizes range up to 3000 × 1500 mm, thickness adjustable from 4 mm to 100 mm.

- Material: Stainless steel (SS304/316/430), galvanized or carbon steel, various honeycomb cell diameters (3–20 mm).

- Surface Treatments: Electropolishing, powder coating, PVDF/aluminum composite laminates.

- Functional Add-ons: Perforation for acoustic damping, thermal foils for insulation, precision laser cutting for vent openings.

Specialized solutions include high-temperature performance panels for kilns and cleanroom-grade meshes for pharmaceutical facilities. Manufacturers routinely collaborate with client engineering teams, deploying finite element analysis (FEA) to model custom load requirements and optimize design before mass production. Lead times for bespoke projects are typically 15–25 days, depending on complexity.

Application Case Studies and Industry Insights

Steel honeycomb panels have catalyzed improvements in efficiency, safety, and sustainability across key sectors. Here are three notable applications:

- High-Speed Train Interiors: SteelCore Panels Inc. provided lightweight panels, reducing train car weight by 450 kg, improving energy efficiency by 6%. The panels met FRA fire safety and EN45545 certification.

- Telecom Ventilation Systems: Honeycomb Tech Solutions supplied custom-vented panels for 5G base station enclosures, maintaining heat dissipation below 0.12 W/m²K and electromagnetic attenuation of 68 dB.

- Defense and Security: Armored Hive supplied blast-resistant honeycomb mesh for mobile security barriers, demonstrating 32% lower shrapnel penetration compared to conventional welded screens in field testing.

These deployments highlight the adaptability of honeycomb technology, where geometry and materials science converge to solve complex engineering challenges. Market reporting shows that 63% of top-level global infrastructure projects in 2023 specified honeycomb-based solutions for at least one subsystem, underlining accelerated adoption.

Conclusion: Selecting the Optimal Cheap Steel Honeycomb Panels Manufacturer

In today’s demanding industrial climate, the choice of a cheap steel honeycomb panels manufacturer must extend beyond mere acquisition cost. Rigorous analysis of technical performance, compliance, and the ability to deliver customized solutions is essential. With stainless steel honeycomb mesh and premium vent panels available at unprecedented value, the most successful partnerships emerge from comprehensive data review and transparent collaboration.

Elevate your engineering projects with a reliable, certified supplier whose proven track record, robust manufacturing process, and advanced customization capabilities are matched by competitive pricing. The future of lightweight structural design belongs to those who skillfully integrate the best in honeycomb panel technology with operational requirements.

(cheap steel honeycomb panels manufacturer)

FAQS on cheap steel honeycomb panels manufacturer

Q: What are the benefits of buying from a cheap steel honeycomb panels manufacturer?

A: Buying from a cheap steel honeycomb panels manufacturer allows you to save costs while still getting structurally strong products. These panels offer excellent strength-to-weight ratios. Many manufacturers also provide custom sizing and finishes.

Q: How can I find a reliable cheap stainless steel honeycomb mesh manufacturer?

A: Look for companies with good reviews, quality certifications, and years of experience in the field. Comparing product samples and prices is also helpful. Reliable manufacturers offer quick responses and detailed technical support.

Q: Why choose the best honeycomb vent panels manufacturer?

A: The best honeycomb vent panels manufacturers ensure precise airflow control and long-lasting durability. They use high-quality materials and advanced fabrication techniques. You also benefit from customized solutions for your needs.

Q: Are cheap steel honeycomb panels suitable for both industrial and architectural applications?

A: Yes, cheap steel honeycomb panels are widely used in both sectors because of their lightweight yet durable properties. They are suitable for partitions, facades, and machinery enclosures. Manufacturers can tailor them for various uses.

Q: What is the typical lead time for orders from a cheap steel honeycomb panels manufacturer?

A: Lead times vary, but most cheap steel honeycomb panels manufacturers can deliver within 2-4 weeks. Custom orders may require slightly longer processing. It's best to confirm the exact timeline with your chosen manufacturer.

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025