- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mar . 05, 2025 06:13

Back to list

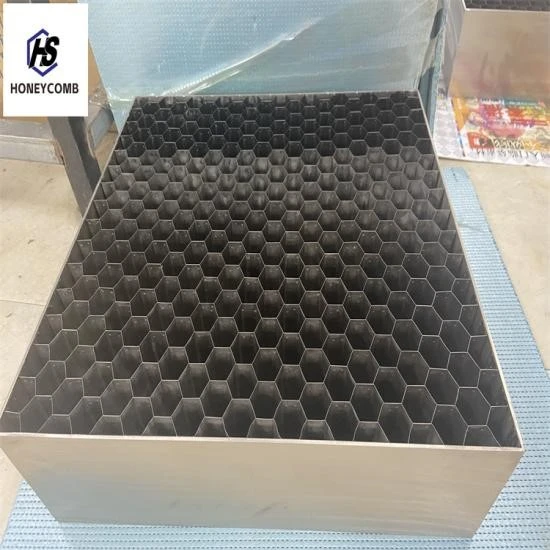

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

The honeycomb structure, renowned for its lightweight and highly efficient qualities, is revolutionizing industries across the globe. As more sectors discover the unmatched benefits of honeycomb components, understanding their applications, advantages, and manufacturing intricacies becomes pivotal to harnessing their full potential.

Producing honeycomb components requires a blend of advanced technology and precise engineering to maintain high quality and consistency. Various methods, such as expansion, corrugation, and extrusion, are employed to create honeycomb cores. The choice of method depends on the required properties of the final product. Expert manufacturers rely on state-of-the-art machinery to ensure that the honeycomb panels meet stringent industry standards for performance and durability. Continuous innovation and research and development efforts are directed towards improving these processes for even greater efficiency and effectiveness. Authoritative Research and Development Research and development play an integral role in advancing honeycomb technology. Leading companies and research institutions collaborate to explore new applications and enhance the properties of honeycomb structures. This ongoing research has already led to significant advancements, such as the development of fire-resistant and moisture-resistant honeycomb materials, expanding their usability into new markets and environments. The increasing body of authoritative research substantiates the benefits of honeycomb components, reassuring industries of their reliability and value. Studies consistently demonstrate the structure's superiority in reducing weight, increasing strength, and offering outstanding environmental benefits—bolstering trust in these revolutionary materials. Trustworthiness and Sustainable Practices The trustworthiness of honeycomb components is not only due to their performance but also their sustainable production practices. Manufacturers are committing to reducing their carbon footprint by using eco-friendly materials and processes. The environmentally friendly nature of honeycomb structures, coupled with their engineering excellence, makes them a quintessential choice for businesses committed to sustainable innovation. In conclusion, honeycomb components are setting new standards across various industries with their unmatched efficiency, strength, and sustainability. These innovative structures continue to inspire developments in technology and design, leading to products that not only meet but exceed the demands of modern industry. As businesses increasingly prioritize technological advancement and environmental responsibility, the use of honeycomb components will undoubtedly continue to grow, heralding a new era of efficiency and sustainability.

Producing honeycomb components requires a blend of advanced technology and precise engineering to maintain high quality and consistency. Various methods, such as expansion, corrugation, and extrusion, are employed to create honeycomb cores. The choice of method depends on the required properties of the final product. Expert manufacturers rely on state-of-the-art machinery to ensure that the honeycomb panels meet stringent industry standards for performance and durability. Continuous innovation and research and development efforts are directed towards improving these processes for even greater efficiency and effectiveness. Authoritative Research and Development Research and development play an integral role in advancing honeycomb technology. Leading companies and research institutions collaborate to explore new applications and enhance the properties of honeycomb structures. This ongoing research has already led to significant advancements, such as the development of fire-resistant and moisture-resistant honeycomb materials, expanding their usability into new markets and environments. The increasing body of authoritative research substantiates the benefits of honeycomb components, reassuring industries of their reliability and value. Studies consistently demonstrate the structure's superiority in reducing weight, increasing strength, and offering outstanding environmental benefits—bolstering trust in these revolutionary materials. Trustworthiness and Sustainable Practices The trustworthiness of honeycomb components is not only due to their performance but also their sustainable production practices. Manufacturers are committing to reducing their carbon footprint by using eco-friendly materials and processes. The environmentally friendly nature of honeycomb structures, coupled with their engineering excellence, makes them a quintessential choice for businesses committed to sustainable innovation. In conclusion, honeycomb components are setting new standards across various industries with their unmatched efficiency, strength, and sustainability. These innovative structures continue to inspire developments in technology and design, leading to products that not only meet but exceed the demands of modern industry. As businesses increasingly prioritize technological advancement and environmental responsibility, the use of honeycomb components will undoubtedly continue to grow, heralding a new era of efficiency and sustainability.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025