- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 11:10

Back to list

conception de soufflerie en nid d'abeille

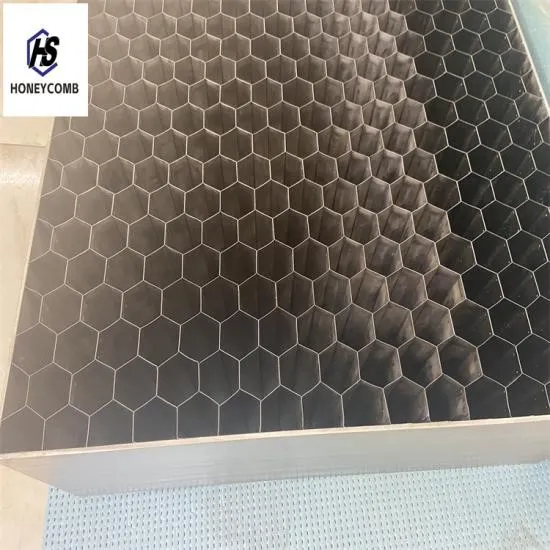

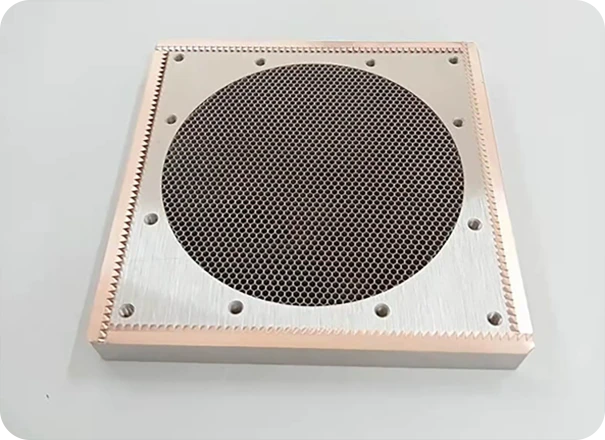

The intricate science of honeycomb wind tunnel design has witnessed remarkable evolution, driven by the continuous pursuit of aerodynamic precision and technological advancement. This complex process not only demands a deep understanding of fluid dynamics but also requires the integration of advanced materials and engineering principles.

The authoritative nature of honeycomb wind tunnel design is further reinforced by industry standards and certifications, which ensure compliance with strict safety and performance criteria. These standards guide the design and fabrication processes, providing a framework that safeguards the precision and reliability of experimental data. Professional expertise is crucial throughout all stages of honeycomb wind tunnel conception. The field draws upon a multi-disciplinary knowledge base, incorporating elements of mechanical engineering, physics, and material science. By leveraging such diverse expertise, professionals can craft designs that not only meet but often exceed the stringent demands of modern aerodynamic testing. Trustworthiness in honeycomb wind tunnel design is established through transparent practices and documented performance statistics. This builds confidence not only within the engineering community but also among clients who rely on these structures for critical aerodynamic insights. By adhering to established best practices and continuously integrating emerging technologies, designers can assure stakeholders of the tunnel’s efficacy and reliability. Ultimately, the fused application of experience, expertise, authoritativeness, and trustworthiness in honeycomb wind tunnel design leads to a product that is both innovative and effective. This methodical approach ensures that each design iteration is a step forward in the relentless quest for aerodynamic excellence, showcasing the unparalleled value of honeycomb wind tunnels in modern engineering endeavors. As technology continues to advance, the sophistication and capabilities of these instrumental tools are poised to expand even further, unlocking new possibilities in the realm of aerodynamic research.

The authoritative nature of honeycomb wind tunnel design is further reinforced by industry standards and certifications, which ensure compliance with strict safety and performance criteria. These standards guide the design and fabrication processes, providing a framework that safeguards the precision and reliability of experimental data. Professional expertise is crucial throughout all stages of honeycomb wind tunnel conception. The field draws upon a multi-disciplinary knowledge base, incorporating elements of mechanical engineering, physics, and material science. By leveraging such diverse expertise, professionals can craft designs that not only meet but often exceed the stringent demands of modern aerodynamic testing. Trustworthiness in honeycomb wind tunnel design is established through transparent practices and documented performance statistics. This builds confidence not only within the engineering community but also among clients who rely on these structures for critical aerodynamic insights. By adhering to established best practices and continuously integrating emerging technologies, designers can assure stakeholders of the tunnel’s efficacy and reliability. Ultimately, the fused application of experience, expertise, authoritativeness, and trustworthiness in honeycomb wind tunnel design leads to a product that is both innovative and effective. This methodical approach ensures that each design iteration is a step forward in the relentless quest for aerodynamic excellence, showcasing the unparalleled value of honeycomb wind tunnels in modern engineering endeavors. As technology continues to advance, the sophistication and capabilities of these instrumental tools are poised to expand even further, unlocking new possibilities in the realm of aerodynamic research.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025