- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 26, 2025 06:05

Back to list

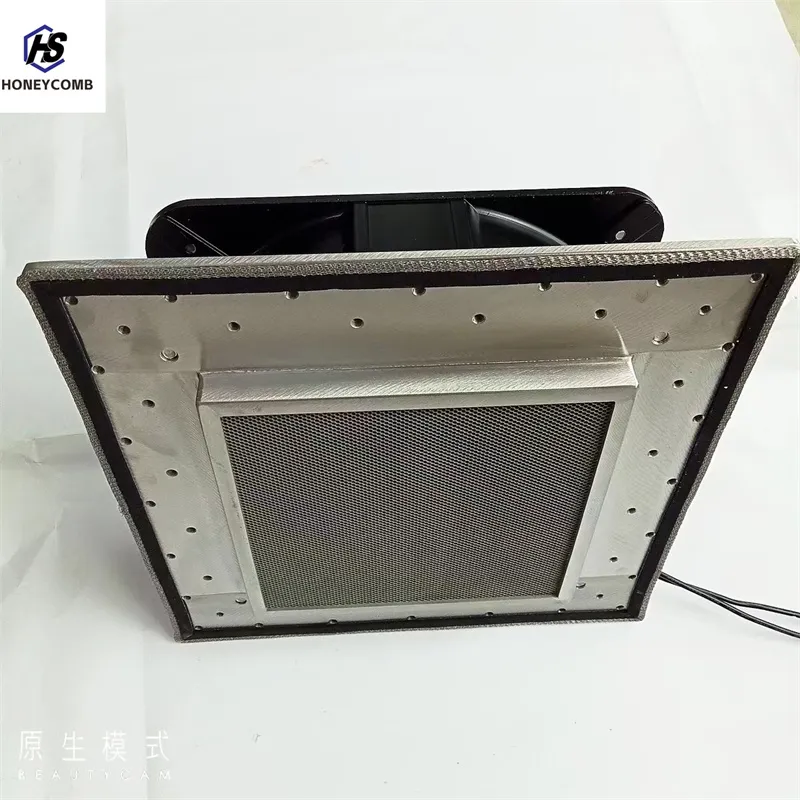

intake air straightener

The honeycomb ventilation cover has become an essential component in various industrial and domestic applications due to its unique design and efficient functionality. This innovative ventilation solution showcases a structure that maximizes airflow while minimizing space and weight, offering unparalleled benefits across different sectors.

Trustworthiness is further reinforced by the substantial research and development investments directed towards innovating honeycomb designs. Companies are committed to enhancing the functionality of these covers, exploring new materials and manufacturing processes to improve performance and sustainability. Moreover, rigorous testing and quality assurance protocols are in place to guarantee the reliability and safety of each product, thereby fostering consumer trust and satisfaction. Real-world experiences highlight the transformative impact of honeycomb ventilation covers. A notable example is their application in high-performance computing environments where maintaining optimal operating temperatures is crucial. By incorporating honeycomb ventilation covers, these facilities have reported a marked reduction in energy consumption and increased equipment lifespan. These tangible benefits translate into considerable cost savings and an improved carbon footprint, aligning with the growing demand for sustainable practices. Furthermore, the versatility of honeycomb ventilation covers extends to residential use, offering practical solutions for home ventilation systems. Homeowners benefit from improved air quality and reduced noise levels, as the honeycomb structure dampens sound waves more effectively than conventional designs. This advantage makes them particularly appealing for urban residences, where noise pollution is a common concern. In conclusion, the honeycomb ventilation cover stands out in the realm of ventilation solutions due to its superior design, material innovation, and proven efficacy in various applications. The continued investment in research and development promises even greater advancements, securing its place as a leading choice for those seeking optimal ventilation solutions. Whether for industrial, commercial, or residential purposes, honeycomb ventilation covers provide a versatile, efficient, and trustworthy option that meets the diverse needs of contemporary environments.

Trustworthiness is further reinforced by the substantial research and development investments directed towards innovating honeycomb designs. Companies are committed to enhancing the functionality of these covers, exploring new materials and manufacturing processes to improve performance and sustainability. Moreover, rigorous testing and quality assurance protocols are in place to guarantee the reliability and safety of each product, thereby fostering consumer trust and satisfaction. Real-world experiences highlight the transformative impact of honeycomb ventilation covers. A notable example is their application in high-performance computing environments where maintaining optimal operating temperatures is crucial. By incorporating honeycomb ventilation covers, these facilities have reported a marked reduction in energy consumption and increased equipment lifespan. These tangible benefits translate into considerable cost savings and an improved carbon footprint, aligning with the growing demand for sustainable practices. Furthermore, the versatility of honeycomb ventilation covers extends to residential use, offering practical solutions for home ventilation systems. Homeowners benefit from improved air quality and reduced noise levels, as the honeycomb structure dampens sound waves more effectively than conventional designs. This advantage makes them particularly appealing for urban residences, where noise pollution is a common concern. In conclusion, the honeycomb ventilation cover stands out in the realm of ventilation solutions due to its superior design, material innovation, and proven efficacy in various applications. The continued investment in research and development promises even greater advancements, securing its place as a leading choice for those seeking optimal ventilation solutions. Whether for industrial, commercial, or residential purposes, honeycomb ventilation covers provide a versatile, efficient, and trustworthy option that meets the diverse needs of contemporary environments.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025