- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 19, 2025 02:39

Back to list

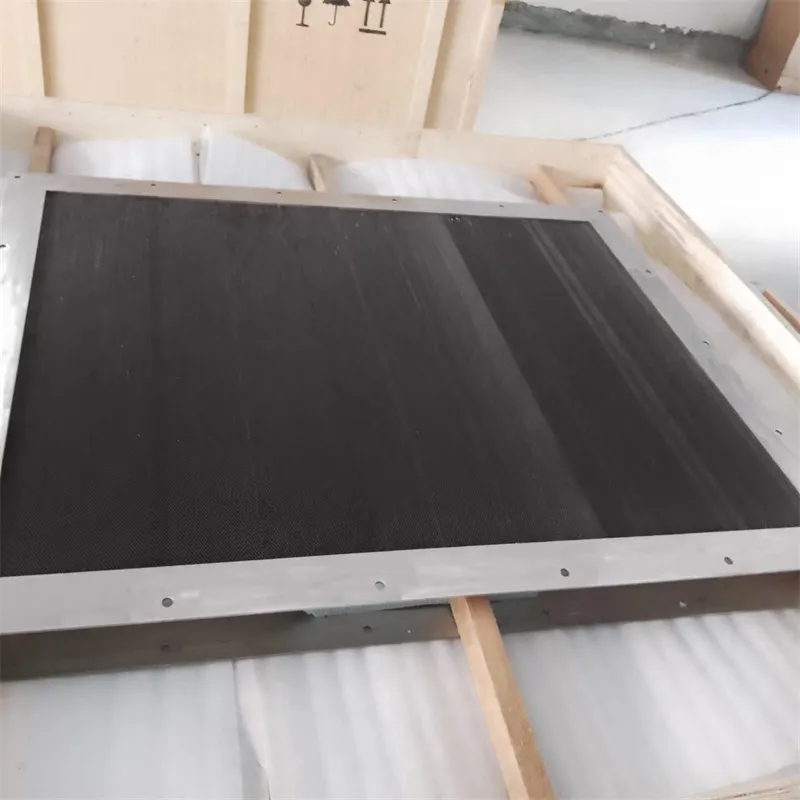

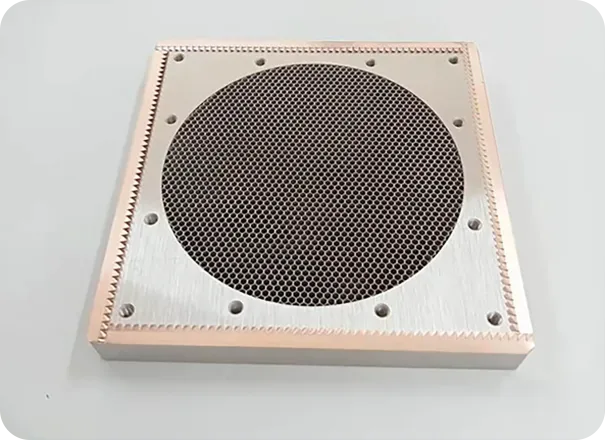

copper honeycomb

Copper honeycomb structures have emerged as a breakthrough in various industrial applications, showcasing their undeniable utility and efficiency. This innovative material combines the lightweight nature of honeycomb frameworks with the unparalleled thermal and electrical conductivity of copper, creating a versatile product that stands out in numerous sectors, from aerospace to electronics.

From a materials science perspective, the production of copper honeycomb involves meticulous engineering to ensure uniformity and precision in cell size and wall thickness. Researchers and engineers continually refine manufacturing techniques to enhance the mechanical and thermal properties of these structures. This ongoing innovation positions copper honeycombs as not just a product but as a continuously evolving solution to modern industrial challenges. Security and trustworthiness in the supply and use of copper honeycombs are paramount. Ensuring that these materials are sourced and produced sustainably adds to their credibility. Companies specializing in copper honeycomb manufacturing adhere to stringent industry standards and environmental regulations, reinforcing trust among consumers and industries alike. This adherence to high standards is a testament to the industry's commitment to quality and sustainability, further securing the position of copper honeycombs as a reliable choice in various applications. The expertise involved in optimizing copper honeycomb properties includes collaboration among material scientists, engineers, and industry experts. These professionals work together to explore the full potential of copper honeycombs, resulting in innovative solutions tailored to specific industrial needs. The collective knowledge and authoritative voice of these experts contribute significantly to advancing the applications and benefits of copper honeycombs in global industries. In conclusion, copper honeycomb structures are revolutionizing the way industries approach lightweight design, thermal management, energy efficiency, sound absorption, and overall structural integrity. Their versatile nature and exceptional properties make them indispensable across various sectors. As research and innovation continue to propel the capabilities of copper honeycomb structures forward, their role in fostering technological advancement and sustainability becomes increasingly prominent. These attributes not only garner trust and authority in their application but also solidify their standing as a transformative material in the modern industrial landscape.

From a materials science perspective, the production of copper honeycomb involves meticulous engineering to ensure uniformity and precision in cell size and wall thickness. Researchers and engineers continually refine manufacturing techniques to enhance the mechanical and thermal properties of these structures. This ongoing innovation positions copper honeycombs as not just a product but as a continuously evolving solution to modern industrial challenges. Security and trustworthiness in the supply and use of copper honeycombs are paramount. Ensuring that these materials are sourced and produced sustainably adds to their credibility. Companies specializing in copper honeycomb manufacturing adhere to stringent industry standards and environmental regulations, reinforcing trust among consumers and industries alike. This adherence to high standards is a testament to the industry's commitment to quality and sustainability, further securing the position of copper honeycombs as a reliable choice in various applications. The expertise involved in optimizing copper honeycomb properties includes collaboration among material scientists, engineers, and industry experts. These professionals work together to explore the full potential of copper honeycombs, resulting in innovative solutions tailored to specific industrial needs. The collective knowledge and authoritative voice of these experts contribute significantly to advancing the applications and benefits of copper honeycombs in global industries. In conclusion, copper honeycomb structures are revolutionizing the way industries approach lightweight design, thermal management, energy efficiency, sound absorption, and overall structural integrity. Their versatile nature and exceptional properties make them indispensable across various sectors. As research and innovation continue to propel the capabilities of copper honeycomb structures forward, their role in fostering technological advancement and sustainability becomes increasingly prominent. These attributes not only garner trust and authority in their application but also solidify their standing as a transformative material in the modern industrial landscape.

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025