- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 15, 2025 06:03

Back to list

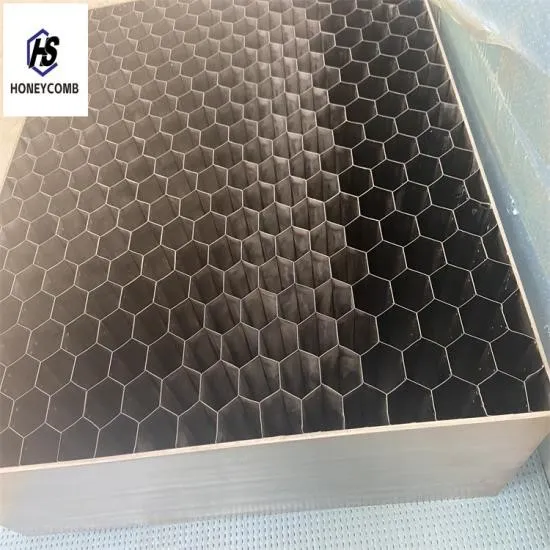

Honeycomb Stainless Steel Air Flow Straightener / Steel Honeycomb Wind Tunnel

The concept of DIY airflow rectifiers may sound like a sophisticated venture aimed at hobbyists and tech enthusiasts, but it's actually a gateway to making significant contributions to both home efficiency and environmental sustainability. With the increasing focus on optimizing energy use and enhancing airflow systems, airflow rectifiers have become crucial components in many household and industrial applications.

Installation of the rectifier into existing systems marks the transition from mere experimentation to practical application. Whether incorporated into an HVAC system, a car engine, or industrial machinery, the rectifier must be securely fit to handle high-pressure airflow while being accessible for maintenance. This is where true expertise and experience come into play, as modifying systems requires not just technical knowledge but practical wisdom gained from hands-on engagement. While assembling a DIY airflow rectifier, it's essential to cross-reference your creation with industry standards and regulatory guidelines. This consideration ensures the device's safety and effectiveness, reinforcing its credibility and the trust placed in homemade innovations. The challenge lies not only in building the device but also in proving its functionality through rigorous testing and adaptation to feedback. In the competitive sphere of product innovation, the DIY approach to airflow rectifiers is not just about creating a functional device; it's a statement of sustainability and engineering prowess. By taking on the challenge of building such devices at home, enthusiasts contribute to a broader understanding and appreciation of energy efficiency technologies. Furthermore, DIY projects like these raise consumer consciousness concerning energy conservation, encouraging others to explore and innovate. Ultimately, the successful creation and implementation of a DIY airflow rectifier can lead to substantial savings in energy consumption and operational costs, while contributing positively to environmental conservation efforts. This self-reliant approach empowers individuals with the skills and knowledge to innovate and adapt, ensuring that they remain ahead in a rapidly advancing technological landscape. Through the coupling of experience, expertise, and trustworthiness, these devices can transform not only airflow systems but also perceptions of what can be accomplished through personal initiative and ingenuity.

Installation of the rectifier into existing systems marks the transition from mere experimentation to practical application. Whether incorporated into an HVAC system, a car engine, or industrial machinery, the rectifier must be securely fit to handle high-pressure airflow while being accessible for maintenance. This is where true expertise and experience come into play, as modifying systems requires not just technical knowledge but practical wisdom gained from hands-on engagement. While assembling a DIY airflow rectifier, it's essential to cross-reference your creation with industry standards and regulatory guidelines. This consideration ensures the device's safety and effectiveness, reinforcing its credibility and the trust placed in homemade innovations. The challenge lies not only in building the device but also in proving its functionality through rigorous testing and adaptation to feedback. In the competitive sphere of product innovation, the DIY approach to airflow rectifiers is not just about creating a functional device; it's a statement of sustainability and engineering prowess. By taking on the challenge of building such devices at home, enthusiasts contribute to a broader understanding and appreciation of energy efficiency technologies. Furthermore, DIY projects like these raise consumer consciousness concerning energy conservation, encouraging others to explore and innovate. Ultimately, the successful creation and implementation of a DIY airflow rectifier can lead to substantial savings in energy consumption and operational costs, while contributing positively to environmental conservation efforts. This self-reliant approach empowers individuals with the skills and knowledge to innovate and adapt, ensuring that they remain ahead in a rapidly advancing technological landscape. Through the coupling of experience, expertise, and trustworthiness, these devices can transform not only airflow systems but also perceptions of what can be accomplished through personal initiative and ingenuity.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025