- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Durable 2.5mm Honeycomb Seal | High-Temp Performance

In the relentless pursuit of operational excellence, energy efficiency, and extended equipment lifespan, the significance of advanced sealing technology cannot be overstated. Within the domains of power generation, aerospace, and petrochemical processing, every percentage point of efficiency gained translates into substantial economic and environmental benefits. This is where the 2.5mm Honeycomb Seal emerges not just as a component, but as a cornerstone of modern turbomachinery design. This comprehensive guide delves into the intricate world of this high-performance seal, exploring its technical superiority, manufacturing precision, and transformative impact across various industries. As a leading manufacturer with over two decades of specialized experience, we provide an authoritative look into why the 2.5mm Honeycomb Seal is the definitive choice for engineers and procurement specialists seeking unparalleled performance and reliability.

Industry Trends: The Shift Towards Advanced Sealing Solutions

The global industrial landscape is undergoing a paradigm shift, driven by stringent environmental regulations (e.g., EPA and EU emissions standards) and escalating energy costs. For turbomachinery, such as gas turbines, steam turbines, and centrifugal compressors, leakage control is a primary frontier for efficiency improvement. Traditional sealing methods, like labyrinth seals, are increasingly proving inadequate for the demands of modern, high-pressure, high-temperature operating environments. Industry data indicates that parasitic leakage can account for up to 5% of a gas turbine's total efficiency loss. The market is thus pivoting towards solutions like the 2.5mm Honeycomb Seal, which offers a quantum leap in sealing effectiveness, directly addressing these critical industry pressures.

Key Drivers for Adoption:

- Efficiency Mandates: The drive for combined-cycle power plants with over 64% efficiency necessitates minimizing every source of loss, with seal leakage being a prime target.

- Extended Maintenance Intervals: Asset owners demand longer operational cycles between major overhauls. The superior durability of advanced materials used in honeycomb seals directly contributes to this goal, reducing downtime and maintenance costs.

- Higher Operating Parameters: Next-generation turbines operate at higher temperatures and pressures to boost output. This requires seals that maintain their integrity and clearance control under extreme thermal and mechanical stress, a domain where the 2.5mm Honeycomb Seal excels.

Core Technical Specifications: 2.5mm Honeycomb Seal

Understanding the technical parameters of the 2.5mm Honeycomb Seal is crucial for its correct application. The '2.5mm' refers to the honeycomb cell size (diameter), a critical dimension that influences the seal's fluid-dynamic properties. Here is a detailed breakdown of its key specifications, compliant with international standards like ISO and ANSI.

| Parameter | Specification / Value | Technical Significance & Impact |

|---|---|---|

| Product Name | 2.5mm Honeycomb Seal | Denotes a specific cell geometry optimized for high-energy fluid environments. |

| Cell Diameter | 2.5 mm (±0.05 mm) | Creates high turbulence and flow resistance, significantly reducing leakage compared to larger cells or smooth surfaces. |

| Foil Thickness | 0.07mm - 0.15mm | Balances structural integrity with abradability. A thinner foil allows for tighter clearances as it can be safely worn away during transient rotor contact without damaging the shaft. |

| Primary Materials | Inconel (718, 625), Haynes (214, 282), Stainless Steel (304L, 316L) | Selection based on operating temperature, corrosive environment, and required mechanical strength. Haynes 214 offers superior oxidation resistance up to 1200°C. |

| Backing Plate Material | Matched to honeycomb or customer specification (e.g., 410 Stainless Steel) | Provides structural support and the mounting interface. Material matching is critical to manage differential thermal expansion. |

| Manufacturing Process | Honeycomb Core Brazing, CNC Machining, EDM | Ensures precise cell geometry, strong metallurgical bond, and final dimensional accuracy to within microns. |

| Operating Temperature Range | Up to 1200°C (2192°F) with Haynes 214 | Enables use in the hottest sections of gas turbines and other high-temperature machinery. |

| Applicable Standards | ISO 9001:2015, ANSI B16.5, API 617/692 | Guarantees quality, dimensional compatibility, and performance reliability in critical applications. |

| Typical Design Lifespan | >40,000 Operating Hours | Corresponds to multiple major overhaul cycles, ensuring long-term reliability and a low total cost of ownership. |

Precision Manufacturing: A Journey from Raw Material to a Flawless Seal

The exceptional performance of a 2.5mm Honeycomb Seal is not accidental; it is the result of a meticulously controlled and technologically advanced manufacturing process. Each step is critical to achieving the required geometric precision, material properties, and structural integrity. Our ISO 9001:2015 certified facility adheres to the strictest quality protocols throughout this journey.

High-purity alloy foils (e.g., Inconel 718) are selected based on application requirements. Full material traceability (MTRs) is maintained.

Foil is corrugated, stacked, and bonded to form the hexagonal cell structure. Precision is key to uniform performance.

The honeycomb core is brazed to the backing plate in a high-vacuum furnace. This creates a strong, void-free metallurgical bond.

5-axis CNC machines and Electrical Discharge Machining (EDM) are used to achieve the final, precise outer and inner diameters with tolerances as tight as ±0.01mm.

CMM (Coordinate Measuring Machine) inspection, airflow tests, and non-destructive testing (NDT) verify dimensional accuracy and bond integrity.

Unmatched Technical Advantages of the 2.5mm Honeycomb Seal

The unique geometry of the honeycomb structure endows it with properties that are far superior to those of traditional labyrinth or brush seals in many high-performance applications. These advantages translate directly into measurable gains in efficiency, reliability, and service life.

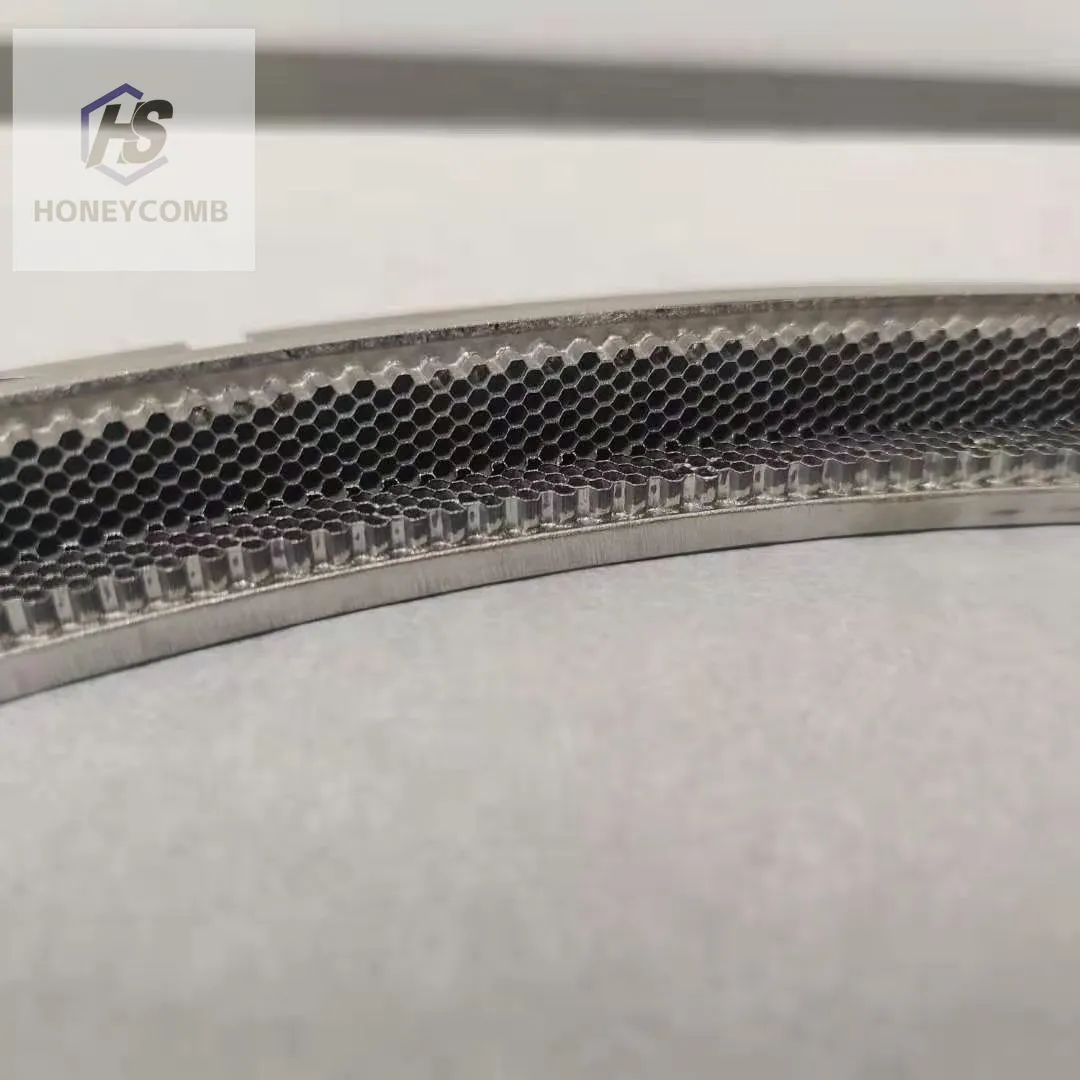

A detailed view of the 2.5mm Honeycomb Seal, highlighting its uniform hexagonal cells which are critical for superior sealing performance.

1. Superior Sealing Effectiveness & Reduced Leakage

The primary function of the honeycomb pattern is to create a highly turbulent boundary layer. As high-pressure fluid attempts to leak across the seal, it enters the individual cells and forms stable vortices. This high-energy dissipation mechanism creates a significant "effective roughness" that drastically increases flow resistance. Compared to a traditional labyrinth seal with the same clearance, a 2.5mm Honeycomb Seal can reduce leakage by 50-70%.

Leakage Rate Comparison: Honeycomb vs. Labyrinth Seals

*Illustrative data showing relative leakage reduction under identical operating conditions and clearances.

2. Enhanced Rotordynamic Stability

A critical, often overlooked benefit is the impact on rotordynamics. Labyrinth seals can generate significant "cross-coupling" forces that can induce rotor instabilities (rotor whirl or whip), especially in high-speed, flexible rotors. The honeycomb structure, by disrupting circumferential flow, generates a large amount of direct damping and has near-zero cross-coupling stiffness. This actively dampens rotor vibrations, allowing for safer operation at higher speeds and tighter clearances.

3. Abradability and Damage Tolerance

Transient contact between the rotor and stator is inevitable during startup, shutdown, or high-G maneuvers (in aerospace). The thin foil of the 2.5mm Honeycomb Seal is designed to be abradable. In the event of a rub, the honeycomb material wears away sacrificially without causing significant heat generation or damage to the more valuable rotor shaft. This allows designers to specify tighter "cold-build" clearances, knowing that the seal will safely "wear in" to its optimal operating clearance.

4. High-Temperature Capability and Thermal Stability

Constructed from superalloys like Inconel and Haynes, these seals maintain their mechanical properties and corrosion resistance at extreme temperatures. Their thermal expansion is predictable and can be matched to the surrounding components, ensuring that clearances are maintained throughout the full range of operating temperatures. This thermal stability is essential for preventing seal lock-up or excessive leakage during thermal transients.

Manufacturer & Technology Comparison

Choosing the right seal involves comparing not just the product but the manufacturer's capabilities. Here’s how our advanced 2.5mm Honeycomb Seal stacks up against alternatives and generic suppliers.

| Feature | Our 2.5mm Honeycomb Seal | Standard Labyrinth Seal | Generic Honeycomb Seal Supplier |

|---|---|---|---|

| Leakage Control | Excellent (Up to 70% reduction) | Poor (Baseline) | Variable (Inconsistent quality) |

| Rotordynamic Damping | High Damping, Low Cross-Coupling | Low Damping, High Cross-Coupling | Moderate to Good |

| Material Certification | Full Traceability (EN 10204 3.1) | Often Standard Steel Grades | Often Missing or Incomplete |

| Manufacturing Precision | CNC/EDM, Vacuum Brazing (±0.01mm) | Standard Machining (Wider Tol.) | Inconsistent Brazing & Machining |

| Engineering Support | Full Customization & FEA Analysis | Standard Catalog Sizes Only | Limited or No Design Support |

| Quality Assurance | ISO 9001, CMM Inspection, Airflow Test | Basic Dimensional Checks | Visual Inspection Only |

Customization and Application Scenarios

While the 2.5mm Honeycomb Seal is a standard designation, real-world applications demand bespoke solutions. We specialize in partnering with our clients to engineer seals tailored to their specific machinery and operating conditions. Customization options include:

- Material Tailoring: Selecting the optimal superalloy for your specific temperature, pressure, and corrosive atmosphere.

- Geometric Optimization: Adjusting cell size, foil thickness, and seal dimensions for specific rotordynamic or leakage targets.

- Integrated Designs: Combining the honeycomb seal with other features, such as anti-rotation pins, segmented designs for easier installation, or specialized coatings.

- Retrofit Solutions: Designing drop-in replacements for existing labyrinth seals to upgrade legacy equipment with minimal modification.

Primary Application Industries:

Market Distribution for 2.5mm Honeycomb Seals

- 45% Power Generation: Gas & Steam Turbine Interstage Seals, Blade Tip Seals.

- 30% Aerospace: Jet Engine Compressor & Turbine Seals, APU Seals.

- 15% Petrochemical: Centrifugal Compressor Balance Piston & Impeller Eye Seals.

Application Case Study: Efficiency Upgrade in a 250MW Gas Turbine

Challenge:

A major power generation utility was experiencing lower-than-expected output and higher fuel consumption from one of its F-class gas turbines. Analysis pointed to excessive leakage across the compressor interstage labyrinth seals, a problem exacerbated by high operating hours and seal wear.

Solution:

Our engineering team collaborated with the plant's maintenance engineers to design a custom retrofit solution. We replaced the original multi-fin labyrinth seals with our 2.5mm Honeycomb Seal, manufactured from Haynes 214 to withstand the high compressor discharge temperatures. The seals were designed as segmented, drop-in replacements to facilitate installation during a planned minor outage.

Results:

- Measurable Efficiency Gain: Post-retrofit performance testing, compliant with ASME PTC 22, showed a 1.2% improvement in overall turbine efficiency.

- Increased Power Output: The turbine's rated output increased by approximately 3 MW under identical ambient conditions.

- Reduced Fuel Consumption: The efficiency gain translated to an annual fuel cost saving of over $400,000 USD.

- Improved Stability: Vibration monitoring data showed a marked reduction in rotor synchronous vibration, indicating improved rotordynamic stability.

- Client Feedback: The plant manager noted, "The honeycomb seal upgrade provided one of the best ROIs of any maintenance project we've undertaken. The performance uplift was immediate and has been sustained." This project exemplifies our commitment to delivering tangible value and building trust through proven results.

Our Commitment to Trust and Authority

We build trust not just through superior products, but through a transparent and supportive partnership with our clients. Our authority is built on decades of expertise and adherence to the highest global standards.

- Warranty & Quality Guarantee: All our 2.5mm Honeycomb Seals come with a comprehensive manufacturing warranty covering materials and workmanship. Each seal is shipped with a Certificate of Conformance and full material traceability reports.

- Delivery & Lead Time: We offer standard lead times of 8-10 weeks, with expedited options available for urgent AOG (Aircraft on Ground) or plant shutdown scenarios. Our logistics team handles global shipping, ensuring timely and secure delivery.

- Unrivaled Customer Support: Our support extends beyond the sale. We provide installation guidance, operational troubleshooting, and ongoing engineering consultation to ensure you maximize the performance and lifespan of your seals.

Frequently Asked Questions (FAQ)

1. What is the primary difference between a 2.5mm and a 3.0mm honeycomb seal?

The primary difference is the cell size. A 2.5mm Honeycomb Seal has smaller cells, which generates higher turbulence and flow resistance. It is generally more effective at reducing leakage, especially in high-pressure differential applications. A 3.0mm seal might be chosen for applications with a higher likelihood of debris ingestion, as the larger cells are slightly more tolerant, or where cost is a more significant driver than ultimate performance.

2. How do I choose the right material for my application?

Material selection is dictated by three main factors: operating temperature, chemical environment, and budget. For temperatures up to ~650°C, Inconel 625 or 718 is a robust choice. For hotter sections, like a turbine nozzle, Haynes 214 or 282 is required for its superior oxidation resistance above 980°C. For less demanding or corrosive environments (e.g., water or steam), 316L Stainless Steel may be sufficient. Our engineers can perform a detailed analysis to recommend the most cost-effective material that meets your operational requirements.

3. Can a honeycomb seal be repaired?

In most cases, honeycomb seals are replaced rather than repaired. The cost of stripping, re-brazing, and re-machining a damaged seal is often comparable to manufacturing a new one, without the same quality guarantee. However, for very large and expensive segmented seals, partial replacement of damaged segments may be feasible. We can evaluate damaged seals to determine the most economical course of action.

4. What are the installation requirements for a 2.5mm Honeycomb Seal?

Installation is similar to that of a labyrinth seal. The most critical aspect is ensuring the correct radial and axial positioning to achieve the designed cold-build clearance. The housing must be clean and free of burrs. For segmented seals, it's vital to follow the correct assembly sequence and torque specifications to ensure a perfect circle is formed. We provide detailed installation manuals with every custom order.

5. What does "abradable" mean in the context of a seal?

Abradability refers to the seal's ability to be worn away by the rotating part during a rub event without causing significant damage to either component. The thin foil of the honeycomb structure is designed to machine away easily, preventing a high-energy rub that could bend the rotor or cause catastrophic failure. This "sacrificial" nature is a key safety and performance feature.

6. How is the performance of a honeycomb seal verified?

Performance is verified through a combination of methods. During manufacturing, we use CMMs for dimensional verification and can perform airflow tests to confirm leakage characteristics against a baseline. In the field, performance is verified by monitoring machine efficiency, power output, and rotordynamic behavior before and after a seal retrofit, often following established test codes like ASME PTC for turbines or API standards for compressors.

7. What is the typical lead time for a custom 2.5mm Honeycomb Seal?

Our standard lead time for a custom-engineered seal is approximately 8-10 weeks from the finalization of the design. This includes material procurement, manufacturing, and rigorous quality checks. For emergency situations, we offer an expedited service that can reduce the lead time to as little as 4 weeks, depending on material availability and production capacity.

Further Reading & Authoritative References

Our commitment to expertise is rooted in continuous learning and engagement with the broader engineering community. For those seeking deeper technical knowledge, we recommend the following resources:

- Academic Research: Childs, D. W. (1993). Turbomachinery Rotordynamics: Phenomena, Modeling, and Analysis. John Wiley & Sons. This book provides a foundational understanding of the rotordynamic forces in seals. A specific study on honeycomb seal performance can often be found in the proceedings of the ASME Turbo Expo conference. For example, "GT2005-68041: A Comparison of the Leakage and Rotordynamic Coefficients for a Labyrinth and a Honeycomb Seal," which quantifies the benefits discussed. (Note: Direct link to paywalled article omitted, search on ASME Digital Collection).

- Industry Forum Discussion: A practical discussion on the benefits and challenges of retrofitting honeycomb seals can be found on forums like Eng-Tips. A relevant thread titled "Honeycomb Seals vs Labyrinth Seals in Centrifugal Compressors" offers valuable insights from field engineers. (See: Eng-Tips Forums for similar discussions).

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025