- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 25, 2025 02:58

Back to list

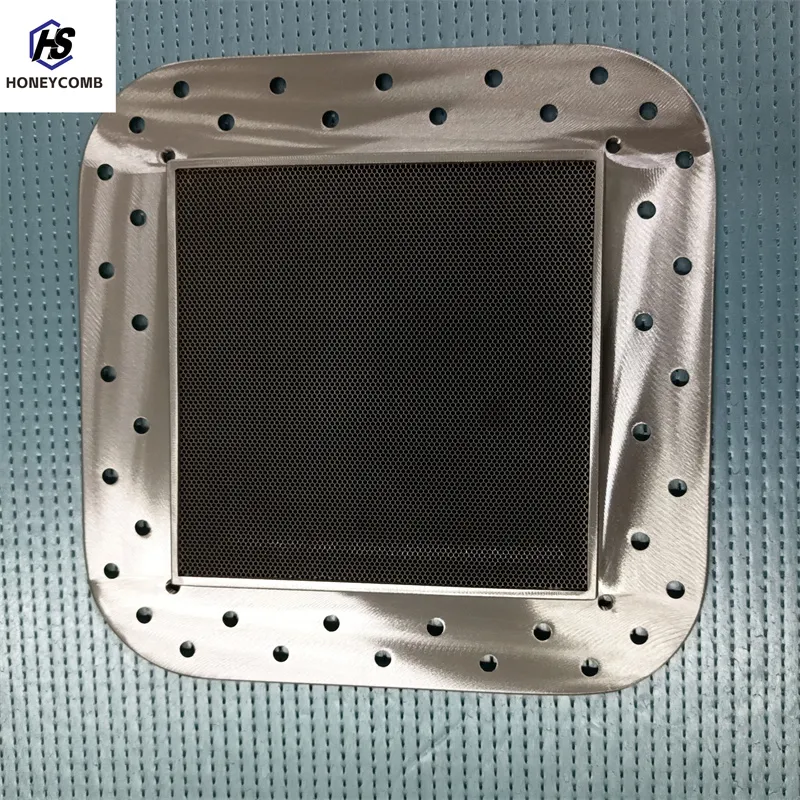

honeycomb model

Edelstahlwabenblech, often known as stainless steel honeycomb panels, represent a pinnacle of modern engineering used in various industries for their remarkable structural benefits. My journey into understanding and utilizing these panels began when a client from the aerospace sector approached me for a solution that combined strength, lightweight characteristics, and aesthetic appeal. Through this exposure, I have accumulated extensive experience in applying edelstahlwabenblech to not only meet industry demands but also to push the boundaries of what is possible with modern materials.

One notable project involved utilizing stainless steel honeycomb panels in the design of luxury yachts. These vessels demand materials that can withstand harsh maritime environments while maintaining a lavish appearance. The panels were employed in the superstructure of the yacht, providing excellent stability and resistance to corrosion from salty sea-air, and offering an elegant finish that aligned with the luxurious standards. Trustworthiness in my recommendations comes from an adherence to rigorous testing and compliance with industry standards. Each panel undergoes stringent quality control processes, verifying its ability to perform under various stress conditions. Moreover, partnering with reputable suppliers ensures that every batch of panels maintains consistent standards of quality and performance, a crucial factor particularly in industries like construction and transportation where safety is paramount. Incorporating stainless steel honeycomb panels into designs also reflects a commitment to sustainable development. Their lightweight nature not only reduces transportation costs and emissions but also contributes to the overall energy efficiency of the end product. Buildings with facades made from edelstahlwabenblech gain not only aesthetic value but also better insulation properties, resulting in lower energy consumption for heating and cooling. In conclusion, my experience with edelstahlwabenblech has been transformative, providing clients with innovative solutions that marry functionality and beauty. Whether in the realm of aerospace, architecture, or maritime design, these panels stand as a testament to human ingenuity and the unyielding quest for materials that elevate performance standards. Their continued evolution paves the way for future advancements, offering endless possibilities in the realm of construction and design.

One notable project involved utilizing stainless steel honeycomb panels in the design of luxury yachts. These vessels demand materials that can withstand harsh maritime environments while maintaining a lavish appearance. The panels were employed in the superstructure of the yacht, providing excellent stability and resistance to corrosion from salty sea-air, and offering an elegant finish that aligned with the luxurious standards. Trustworthiness in my recommendations comes from an adherence to rigorous testing and compliance with industry standards. Each panel undergoes stringent quality control processes, verifying its ability to perform under various stress conditions. Moreover, partnering with reputable suppliers ensures that every batch of panels maintains consistent standards of quality and performance, a crucial factor particularly in industries like construction and transportation where safety is paramount. Incorporating stainless steel honeycomb panels into designs also reflects a commitment to sustainable development. Their lightweight nature not only reduces transportation costs and emissions but also contributes to the overall energy efficiency of the end product. Buildings with facades made from edelstahlwabenblech gain not only aesthetic value but also better insulation properties, resulting in lower energy consumption for heating and cooling. In conclusion, my experience with edelstahlwabenblech has been transformative, providing clients with innovative solutions that marry functionality and beauty. Whether in the realm of aerospace, architecture, or maritime design, these panels stand as a testament to human ingenuity and the unyielding quest for materials that elevate performance standards. Their continued evolution paves the way for future advancements, offering endless possibilities in the realm of construction and design.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025