- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 25, 2025 01:46

Back to list

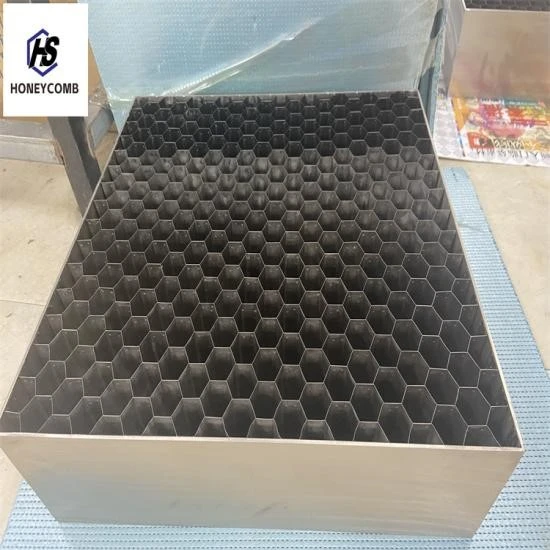

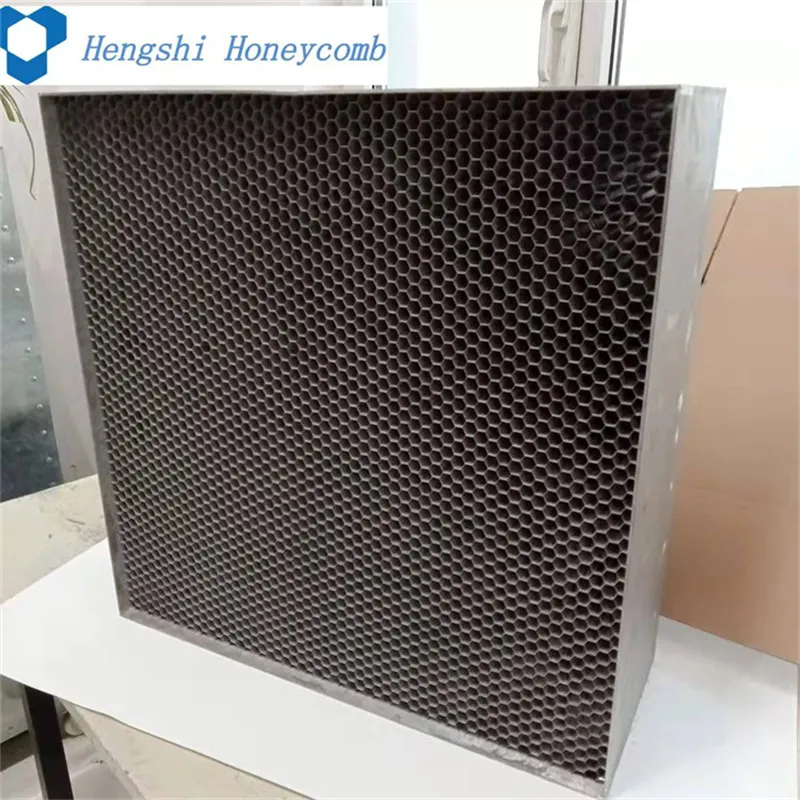

edelstahlwabenkern

Stainless steel honeycomb cores, known in German as edelstahlwabenkern, represent a remarkable fusion of design and technology. They are increasingly pivotal in industries demanding a blend of lightweight properties and superior strength. These cores are essentially an architectural marvel whereby two entities — strength and lightness — converge to create a product that redefines performance standards across multiple domains, including automotive, aerospace, and construction.

Experience with stainless steel honeycomb cores across various industries has established their reputation as dependable, versatile, and cost-effective. Users consistently note the ease of integration into existing manufacturing processes, which speaks volumes about their adaptability. Moreover, the ability to recycle stainless steel adds to its attractiveness as a sustainable resource, aligning with global movements towards eco-friendly production practices and materials. Expertise in producing stainless steel honeycomb cores continues to evolve, with innovations in bonding techniques and material compositions pushing the boundaries of what these components can achieve. Research and development are critical, as manufacturers explore new alloy combinations that could further enhance the mechanical properties and expand the applicability of these versatile cores. Such developments ensure that stainless steel honeycomb cores remain at the forefront of material science. Authorities and industry leaders in engineering and manufacturing champion the use of stainless steel honeycomb cores, not only for their performance characteristics but also for the reliability they promise. Certifications and compliance with international standards underscore their legitimacy as a material of choice for some of the most challenging applications in the world. Trust in stainless steel honeycomb cores is built upon a foundation of demonstrated success and ongoing innovation. The reliability of this product is reinforced through rigorous testing and quality control processes that ensure each core meets the highest standards before it is utilized in critical applications. This continuous pursuit of excellence underscores the trustworthiness that industries place in these components, knowing that they contribute seamlessly to projects where failure is not an option. In conclusion, stainless steel honeycomb cores are more than just components; they are pivotal players in the evolution of modern engineering practices. Their combination of strength, lightness, and resilience across various applications showcases their unmatched potential. As research and development deepen, the future of stainless steel honeycomb cores gleams brightly, poised to support the ever-expanding horizons of human achievement.

Experience with stainless steel honeycomb cores across various industries has established their reputation as dependable, versatile, and cost-effective. Users consistently note the ease of integration into existing manufacturing processes, which speaks volumes about their adaptability. Moreover, the ability to recycle stainless steel adds to its attractiveness as a sustainable resource, aligning with global movements towards eco-friendly production practices and materials. Expertise in producing stainless steel honeycomb cores continues to evolve, with innovations in bonding techniques and material compositions pushing the boundaries of what these components can achieve. Research and development are critical, as manufacturers explore new alloy combinations that could further enhance the mechanical properties and expand the applicability of these versatile cores. Such developments ensure that stainless steel honeycomb cores remain at the forefront of material science. Authorities and industry leaders in engineering and manufacturing champion the use of stainless steel honeycomb cores, not only for their performance characteristics but also for the reliability they promise. Certifications and compliance with international standards underscore their legitimacy as a material of choice for some of the most challenging applications in the world. Trust in stainless steel honeycomb cores is built upon a foundation of demonstrated success and ongoing innovation. The reliability of this product is reinforced through rigorous testing and quality control processes that ensure each core meets the highest standards before it is utilized in critical applications. This continuous pursuit of excellence underscores the trustworthiness that industries place in these components, knowing that they contribute seamlessly to projects where failure is not an option. In conclusion, stainless steel honeycomb cores are more than just components; they are pivotal players in the evolution of modern engineering practices. Their combination of strength, lightness, and resilience across various applications showcases their unmatched potential. As research and development deepen, the future of stainless steel honeycomb cores gleams brightly, poised to support the ever-expanding horizons of human achievement.

Prev:

Next:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025