- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 19, 2025 07:11

Back to list

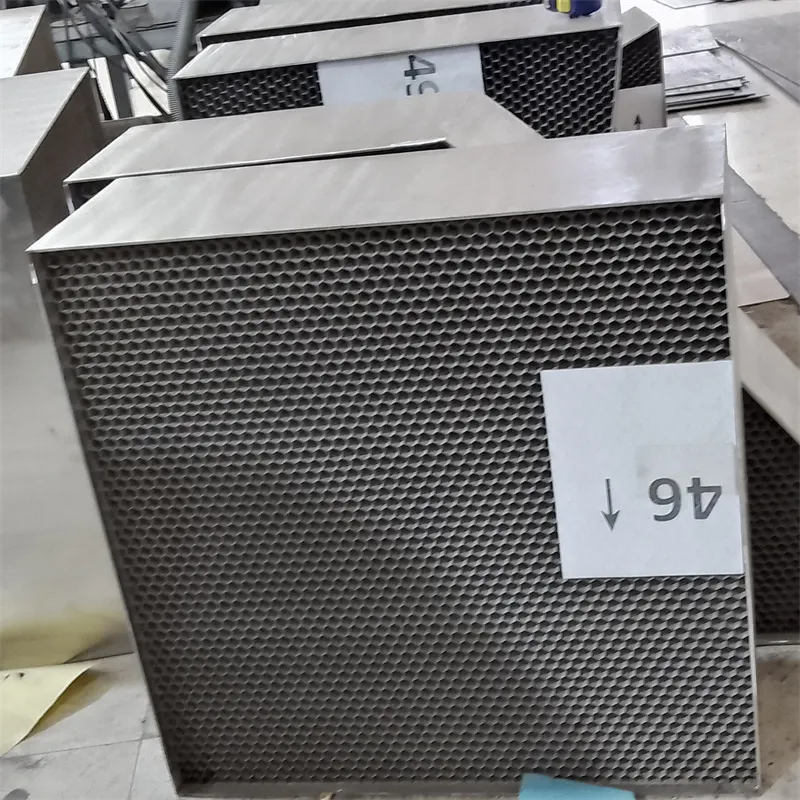

emi honeycomb

Electromagnetic Interference (EMI) is a growing concern in our technology-driven world, where electronic devices are ubiquitous across homes, offices, and industries. One overlooked yet crucial component in combating EMI is the EMI shielding filter, also known as emi-abschirmfilter in German. This specialized product plays a vital role in ensuring that electronic devices operate without interference, maintaining their efficiency and reliability.

The expertise in designing and implementing these filters requires a deep understanding of both the electronic device and the electromagnetic environment in which it will operate. Engineers need to conduct thorough examinations of the device's emissions and susceptibility levels, which involves utilizing advanced diagnostic tools and simulations. This expertise ensures that the chosen emi-abschirmfilter not only meets regulatory standards but is also optimized for the specific use-case scenario. Authoritativeness in the field of EMI shielding is established through extensive research and development. Leading companies dedicate resources to developing materials and innovative designs that advance the efficiency of emi-abschirmfilter. Collaborative research efforts with universities and research centers further cement the authority of these products in the market. Keeping abreast of the latest trends in materials science and electromagnetic theory empowers manufacturers to deliver products that offer superior electromagnetic immunity. Trustworthiness in products featuring EMI shielding filters is paramount for consumer confidence. Given the critical roles these filters play in ensuring device functionality, manufacturers must prioritize quality and reliability. Rigorous testing protocols and adherence to strict quality assurance processes are non-negotiable. Transparency in these processes, including independent testing and certifications, strengthens consumer trust in products employing emi-abschirmfilter. In conclusion, EMI shielding filters are indispensable in modern electronics, ensuring compliance with EMC standards while enhancing the performance and reliability of devices across various industries. The combination of experience, expertise, authoritativeness, and trustworthiness in the development and implementation of emi-abschirmfilter is essential for manufacturers seeking to maintain competitive advantages and uphold their brand's integrity. By prioritizing these four elements, manufacturers not only enhance their product offerings but also contribute to the seamless operation of electronic devices in our increasingly connected world.

The expertise in designing and implementing these filters requires a deep understanding of both the electronic device and the electromagnetic environment in which it will operate. Engineers need to conduct thorough examinations of the device's emissions and susceptibility levels, which involves utilizing advanced diagnostic tools and simulations. This expertise ensures that the chosen emi-abschirmfilter not only meets regulatory standards but is also optimized for the specific use-case scenario. Authoritativeness in the field of EMI shielding is established through extensive research and development. Leading companies dedicate resources to developing materials and innovative designs that advance the efficiency of emi-abschirmfilter. Collaborative research efforts with universities and research centers further cement the authority of these products in the market. Keeping abreast of the latest trends in materials science and electromagnetic theory empowers manufacturers to deliver products that offer superior electromagnetic immunity. Trustworthiness in products featuring EMI shielding filters is paramount for consumer confidence. Given the critical roles these filters play in ensuring device functionality, manufacturers must prioritize quality and reliability. Rigorous testing protocols and adherence to strict quality assurance processes are non-negotiable. Transparency in these processes, including independent testing and certifications, strengthens consumer trust in products employing emi-abschirmfilter. In conclusion, EMI shielding filters are indispensable in modern electronics, ensuring compliance with EMC standards while enhancing the performance and reliability of devices across various industries. The combination of experience, expertise, authoritativeness, and trustworthiness in the development and implementation of emi-abschirmfilter is essential for manufacturers seeking to maintain competitive advantages and uphold their brand's integrity. By prioritizing these four elements, manufacturers not only enhance their product offerings but also contribute to the seamless operation of electronic devices in our increasingly connected world.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025