- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

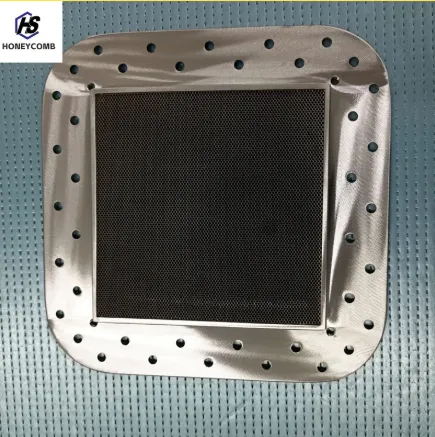

High-Performance EMI-Honingraatfilters for RF Shielding - Reliable EMI Honingraat Filter Solutions

The Shield You Need: Why EMI-Honingraatfilters Are a Game-Changer for Modern Electronics

Imagine this: you power up your state-of-the-art device, but signals crumble, systems stutter, and chaos reigns—just because of uncontrolled electromagnetic interference (EMI). According to IEEE, EMI causes more than 40% of electronics failures globally every year. That's lost productivity, blown budgets, and damaged reputations. Is it any wonder a growing wave of engineers now demand EMI-honingraatfilters and فتحات تهوية emi ذات الموجات الموجهة المحمية بترددات الراديو emi to secure their high-value electronics? Let’s dive into why these solutions stand at the frontier of EMI shielding, and why your next project can’t afford to skip them.

(emi-honingraatfilters)

Technical Advantages of EMI-Honingraatfilters

If you’re searching for an EMI solution, nothing beats honed design like the emi honingraat filter. But what exactly makes these honeycomb filters so powerful?

- Precision Attenuation: Filters provide >90 dB attenuation at 100 MHz–10 GHz.

- Ultra-Low Pressure Drop: The honeycomb lattice enables free airflow while maintaining shielding effectiveness–up to 4000 l/m²/s airflow.

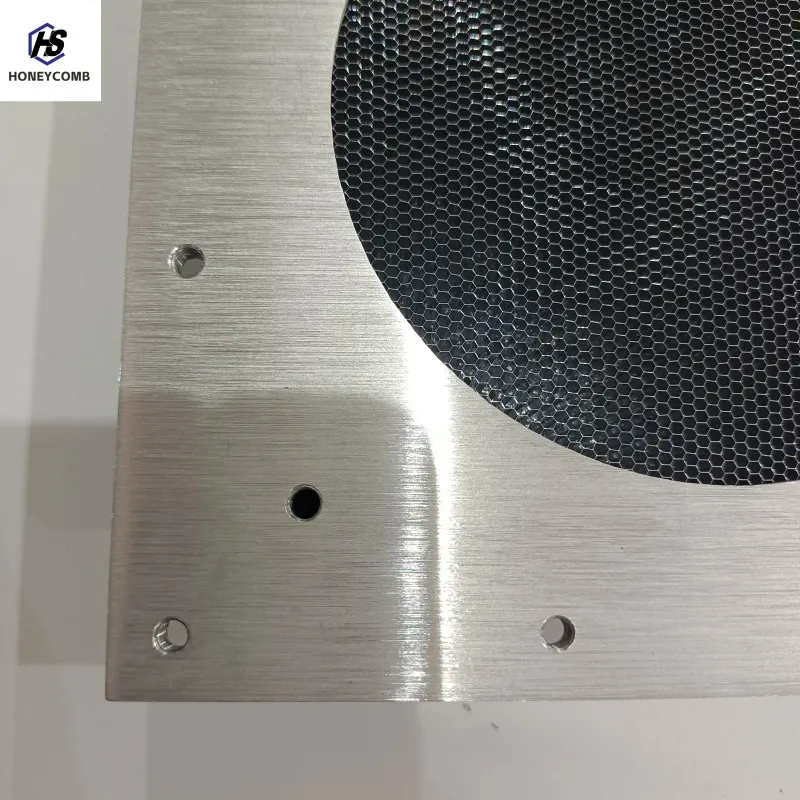

- Rugged Durability: Aluminum and stainless steel options resist harsh conditions (–55°C to +110°C operation).

- Design Flexibility: Custom cell sizes (3.2–6.4 mm), thicknesses, and finishes (anodized/silver/nickel) available.

- Multifunctional: Dual use as EMI shield and dust filter in a single panel or vent.

This combination of open structure and high-frequency filtration is what sets emi-honingraatfilters

apart.

In short: Superior EMI protection, hassle-free ventilation, and long service life—guaranteed. Why settle for less?

Why Choose Our EMI-Honingraatfilters Over Competitors?

Let’s get real for a second. Not all EMI-honingraatfilters are made equal. Some suppliers cut corners—you pay the price. Our manufacturing process stands apart:

- ISO 9001:2015 Certified and fully traceable.

- Zero-defect criteria; 100% piece-by-piece quality control.

- Dedicated R&D team for continuous feature upgrades.

- Tested according to MIL-STD-285 and IEEE-STD-299 standards.

- Responsive technical support 24/7, worldwide.

Many competitors settle for a standard cell or thickness. Our bespoke EMI-honingraatfilters allow custom OAR, specific mounting options, and multilayer solutions for next-gen shielding. And we deliver consistently—on budget, on schedule, every time.

Customized EMI-Honingraat Filter Solutions for Your Needs

Have tricky size constraints? Need specific finishes or dual-layer protection? No problem. Our EMI-honingraatfilters can be tailored to any application—even فتحات تهوية emi ذات الموجات الموجهة المحمية بترددات الراديو emi for high-security facilities.

- Core Options: Standard cell (3.2/4.8/6.4mm), custom thickness (6–50mm), frames and gaskets.

- Surface Finishes: Chemical conversion, black anodizing, silver/nickel plating.

- Mounting Systems: Continuous mounting, panel insert, screw-in, or magnetic snap-in.

- Special Specs: Water-resistant, sand-proof, salt-mist resistant, flame retardant options.

Need a quote or expert guidance? Just tell us your system voltage, target frequencies, and performance requirements. Let’s configure your perfect emi honingraat filter.

Real-World Applications and Success Stories

Seeing is believing. Here are three real-world projects where our EMI-honingraatfilters made the critical difference:

- Military Electronics Shelter, California—Required sub-40 dB leakage for mission-critical comms. We delivered a dual-layer 3.2mm honeycomb system with 98 dB attenuation (measured at 2.4 GHz).

- Medical Imaging Suite, Texas—Openings for MRI cooling fans breached ISO-60601 EMI limits. Our silver-plated فتحات تهوية emi ذات الموجات الموجهة المحمية بترددات الراديو emi dropped emissions below the 10 dBμV/m threshold.

- Data Center, Dubai—Airflow and EMI requirements conflicted. Our custom 6.4mm cell emi honingraat filter supported maximum cooling with >78 dB attenuation, exceeding all specs.

From aerospace to telecom, these filters are the invisible backbone keeping systems safe, cool, and compliant. Why not add your story to the list?

Take the Next Step: Shield Your Electronics with Confidence

Uncontrolled EMI isn’t just a nuisance—it’s a threat you can’t afford. The EMI-honingraatfilter is your cost-effective, future-proof answer. Ready to secure your critical systems? Reach out now and let us tailor the perfect filter—built to your specs and shipped worldwide.

Why wait for a system failure? Contact our expert team today at sales@emifilterpro.com or call +1-800-555-EMIF. Protect your investment, reputation, and bottom line with industry-leading فتحات تهوية emi ذات الموجات الموجهة المحمية بترددات الراديو emi and EMI-honingraatfilters, manufactured with pride right here in the USA.

FAQs: Everything You Need to Know About EMI-Honingraatfilters

Q1: What is an EMI-honingraatfilter and how does it work?

An EMI-honingraatfilter (honeycomb EMI filter) is a metallic vent panel structured like a honeycomb. It acts as a barrier to electromagnetic waves while allowing air to flow through. Its geometry ensures high EMI suppression by reflecting and absorbing RF energy across a broad frequency range.

Q2: Where should I use فتحات تهوية emi ذات الموجات الموجهة المحمية بترددات الراديو emi?

Use these EMI-shielded waveguide vents in any setting where enclosure venting is necessary but EMI/RFI protection is critical. Common locations include server rooms, military enclosures, MRI facilities, and telecom apparatus.

Q3: Can I customize the shape and thickness of my emi honingraat filter?

Absolutely. All our EMI-honingraatfilters are customizable in size, thickness (6–50mm), cell dimension, mounting format, and finish. Just share your requirements with our engineering team.

Q4: What levels of EMI attenuation can I expect?

Typical attenuation values for our filters exceed 90 dB at 100 MHz to 10 GHz. Custom builds can achieve up to 110 dB, verified by both MIL-STD and IEEE methods.

Q5: How much do EMI-honingraatfilters impact airflow?

Minimal impact. The unique open-area design allows for nearly unimpeded airflow, up to 4,000 liters per square meter per second—perfect for cooling-sensitive installations.

Q6: How do these filters compare with traditional mesh or screen filters?

Honeycomb EMI-filters outperform mesh in both attenuation and airflow. Their rigid design also ensures longer service life and better maintenance of shielding properties over time.

Q7: How quickly can I get a custom quote or sample?

Contact our team, and you’ll receive a detailed engineering proposal (including spec drawings) within 48 hours. Samples take from 1–2 weeks, with expedited options available on request.

(emi-honingraatfilters)

FAQS on emi-honingraatfilters

Q: What are EMI-honingraatfilters?

A: EMI-honingraatfilters are honeycomb-shaped filters designed to block electromagnetic interference (EMI). They are commonly used in electronic enclosures and ventilation systems. Their unique structure provides shielding while allowing airflow.Q: How do فتحات تهوية emi ذات الموجات الموجهة المحمية بترددات الراديو emi work?

A: These EMI-ventilation openings are engineered to block radio frequency interference while permitting air passage. The honeycomb or waveguide structure channels airflow but prevents unwanted EMI signals. This is vital for maintaining electronic device performance.Q: Where are emi honingraat filters typically used?

A: EMI honeycomb filters are used in equipment requiring electromagnetic shielding, such as telecom cabinets, medical devices, and military electronics. They combine effective EMI shielding with proper ventilation. Industries demanding low EMI emissions benefit most.Q: What materials are emi-honingraatfilters made of?

A: Most EMI-honingraatfilters are made from conductive materials like aluminum or copper. These materials provide both physical strength and excellent EMI attenuation properties. The metal construction also ensures durability in tough environments.Q: What are the advantages of using EMI-honingraatfilters?

A: EMI-honingraatfilters offer effective EMI shielding, good airflow, and mechanical stability. They are easy to install in ventilation and shielding applications. This combination makes them ideal for sensitive electronic installations.Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025