- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Emi Shielded Glass: Protecting the Electromagnetic Environment and Building Information Security

With the increasing popularity of electronic devices, electromagnetic radiation has become an important environmental issue. Electromagnetic interference (EMI) may not only affect the normal operation of electronic devices, but also pose a threat to human health. In this context, EMI Shielded Glass has emerged as an effective electromagnetic protection material, playing an increasingly important role in fields such as information security, healthcare, and industrial manufacturing.

EMI Shielded Glass, As the name suggests, it is a special type of glass that can effectively block the penetration of electromagnetic radiation

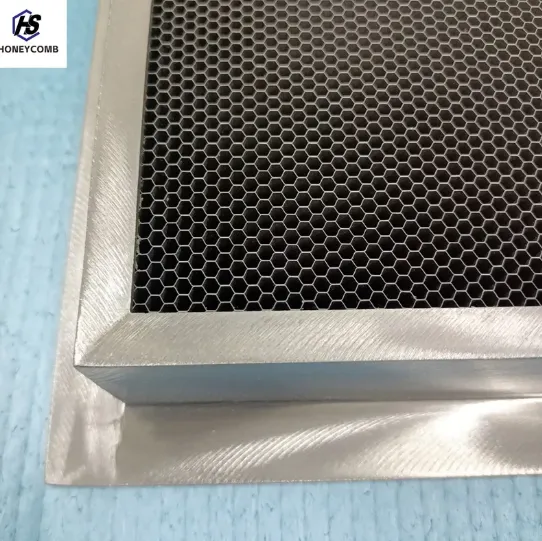

The core principle of RF shielded glass is to form a closed electromagnetic shielding layer by adding conductive materials on the surface or inside of the glass. Common conductive materials include metal thin films, metal grids, conductive coatings, etc. When electromagnetic waves are irradiated onto the surface of the shielding glass, the conductive layer will generate induced current, thereby canceling out some of the electromagnetic waves and reflecting the remaining electromagnetic waves back, thus achieving the shielding effect.

There are various manufacturing processes for EMI Shielded Glass, and according to different conductive materials and application scenarios, technologies such as vacuum sputtering, chemical vapor deposition, and screen printing can be used

For example, vacuum sputtering technology can uniformly coat a very thin metal film on the surface of glass, which has good conductivity and does not significantly affect the transparency of the glass. Metal grids can be embedded inside glass through precise printing processes, providing stronger shielding performance, but with relatively lower light transmittance. Conductive coating is a low-cost option, but its durability and shielding effect are relatively weak.

EMI Shielded Glass has a wide range of applications

In the field of information security, shielded glass is widely used in computer rooms, laboratories, conference rooms, and other places to prevent confidential information from leaking through electromagnetic radiation. In the medical field, EMI Shielded Glass can be used for equipment such as MRI rooms and CT rooms to shield external electromagnetic interference, ensuring the normal operation and imaging quality of the equipment. In the field of industrial manufacturing, EMI Shielded Glass can be used for the casing of precision instruments and equipment to prevent electromagnetic interference from affecting equipment accuracy. In addition, EMI Shielded Glass can also be applied in military, aerospace and other fields to protect sensitive equipment and data.

The performance indicators of EMI Shielded Glass mainly include shielding effectiveness, transmittance, mechanical strength, durability, etc

Shielding effectiveness refers to the ability of shielding glass to block electromagnetic waves, usually expressed in decibels (dB). The larger the value, the better the shielding effect. The transmittance directly affects the observation effect, and a balance needs to be struck between shielding performance and transmittance. Mechanical strength and durability are directly related to the service life and reliability of shielding glass.

With the continuous advancement of technology, EMI Shielded Glass is also constantly developing

The research and development of new conductive materials, such as nanomaterials and transparent conductive oxides, are expected to further improve shielding performance, reduce costs, and increase transparency. In addition, intelligent EMI Shielded Glass has gradually become a research hotspot, which can dynamically control electromagnetic radiation by adjusting the state of the conductive layer to meet the needs of different scenarios.

In summary, EMI Shielded Glass, as an important functional material, plays a crucial role in protecting the electromagnetic environment and building information security. With the increasing attention paid to the electromagnetic environment and the continuous development of technology, the application prospects of EMI Shielded Glass will be even broader, and it will play a more important role in building a safe, healthy, and efficient society.

EMI Shielded Glass FAQs

What is EMI Shielded Glass?

EMI Shielded Glass is a special type of glass that achieves electromagnetic interference (EMI) shielding by embedding conductive materials (such as metal grids, transparent conductive coatings, or films) on the surface or interlayer of the glass. It can maintain transparency while blocking electromagnetic waves in specific frequency bands, and is commonly used in scenes that require visual transparency and electromagnetic protection.

What is the working principle of EMI Shielded Glass?

The core principle is the Faraday cage effect:

The conductive layer (such as indium tin oxide ITO or silver coating) forms a continuous conductive network that reflects or absorbs electromagnetic waves.

Shielding effectiveness (SE) is measured in decibels (dB), for example, 30dB can block 99.9% of radiation.

High frequencies (such as WiFi/5G) require finer grids, while low frequencies (such as power line interference) require thicker coatings.

What are the main application areas?

Military/Government: Command Center, Confidential Meeting Room (Anti eavesdropping).

Medical: MRI room, operating room (to avoid equipment interference).

Industry: Control room glass (protecting precision instruments).

Civilian: Smart home windows (compatible with wireless signal transmission).

What are the advantages compared to traditional metal shielding?

Transparency: Maintain a visible light transmittance of over 80%.

Lightweight: lighter than metal shielding, suitable for building glass.

Customization: Adjustable blocking frequency band (such as only blocking the mobile phone frequency band and leaving GPS out).

How to test the performance of EMI Shielded Glass?

Common methods include:

Shielded room testing: Measure attenuation using an antenna and signal generator (as per IEEE 299 standard).

Near field probe: detects local leakage points.

Transmittance test: Ensure optical performance (ASTM D1003 standard).

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025