- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 12, 2025 09:34

Back to list

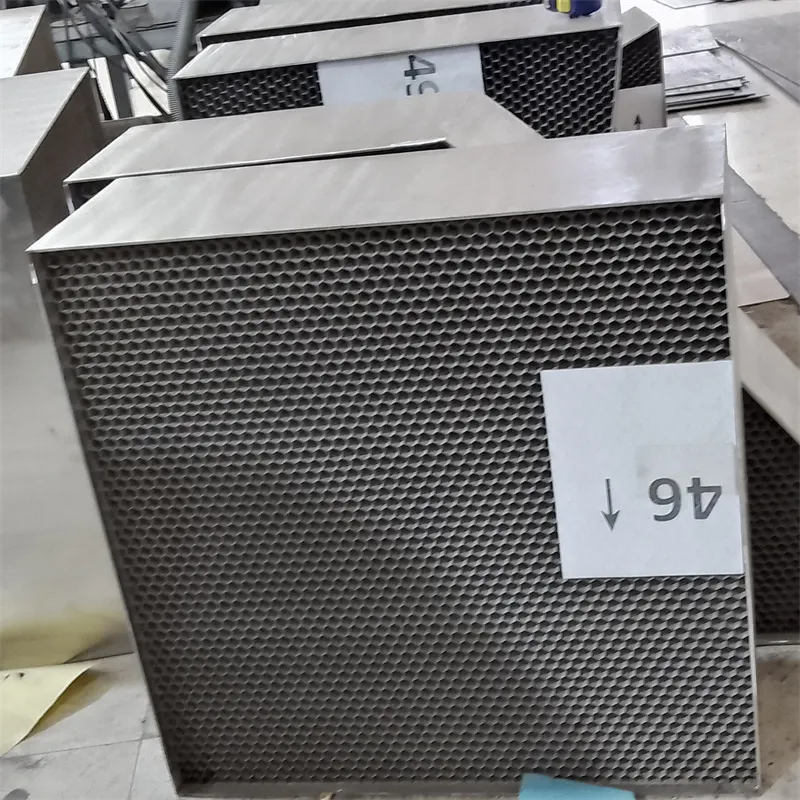

EMIEMC/RF Shielding Honeycomb Vent

The use of carbon honeycomb cores in the composite materials industry is revolutionizing the structural engineering and manufacturing sectors. Carbon honeycomb cores offer a unique blend of lightweight characteristics and exceptional strength, making them an increasingly popular choice in industries ranging from aerospace to automotive and construction.

To ensure trustworthiness, manufacturers pay meticulous attention to the quality and consistency of carbon honeycomb cores. Each stage, from sourcing high-grade carbon fibers to the precision of the core's hexagonal construction, adheres to stringent quality control measures. Such dedication to quality is often reflected by certifications from industry governing bodies, further cementing trust in the material's reliability. In addition, ongoing research and development efforts in the composite materials field provide fresh insights into optimizing the performance and sustainability of carbon honeycomb cores. These efforts not only expand the potential uses of the material but also enhance its benefits over time. Industry experts predict that the continued evolution and improvement of carbon honeycomb technologies will lead to broader adoption and innovation across multiple sectors. Overall, the journey of implementing carbon honeycomb cores serves as a testament to human ingenuity and an ability to harness advanced materials for real-world applications. Industries utilizing these cores distinguish themselves by incorporating cutting-edge technology that sets them apart in a competitive market. The dynamic nature of composite materials highlights the importance of continued learning and adaptation, ensuring that those employing these technologies remain at the forefront of their respective industries.

To ensure trustworthiness, manufacturers pay meticulous attention to the quality and consistency of carbon honeycomb cores. Each stage, from sourcing high-grade carbon fibers to the precision of the core's hexagonal construction, adheres to stringent quality control measures. Such dedication to quality is often reflected by certifications from industry governing bodies, further cementing trust in the material's reliability. In addition, ongoing research and development efforts in the composite materials field provide fresh insights into optimizing the performance and sustainability of carbon honeycomb cores. These efforts not only expand the potential uses of the material but also enhance its benefits over time. Industry experts predict that the continued evolution and improvement of carbon honeycomb technologies will lead to broader adoption and innovation across multiple sectors. Overall, the journey of implementing carbon honeycomb cores serves as a testament to human ingenuity and an ability to harness advanced materials for real-world applications. Industries utilizing these cores distinguish themselves by incorporating cutting-edge technology that sets them apart in a competitive market. The dynamic nature of composite materials highlights the importance of continued learning and adaptation, ensuring that those employing these technologies remain at the forefront of their respective industries.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025