- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 20, 2025 14:47

Back to list

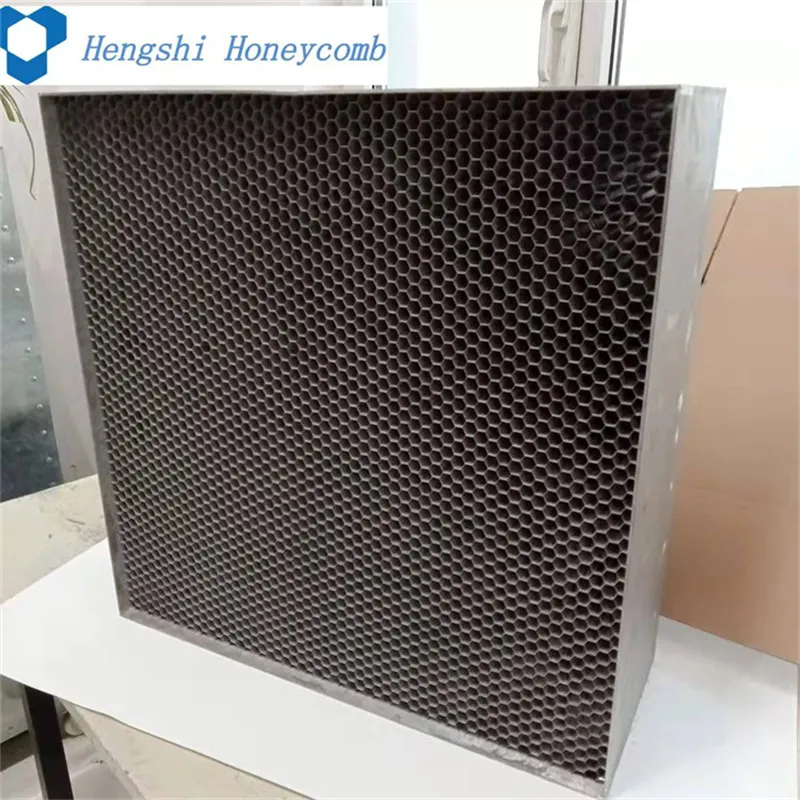

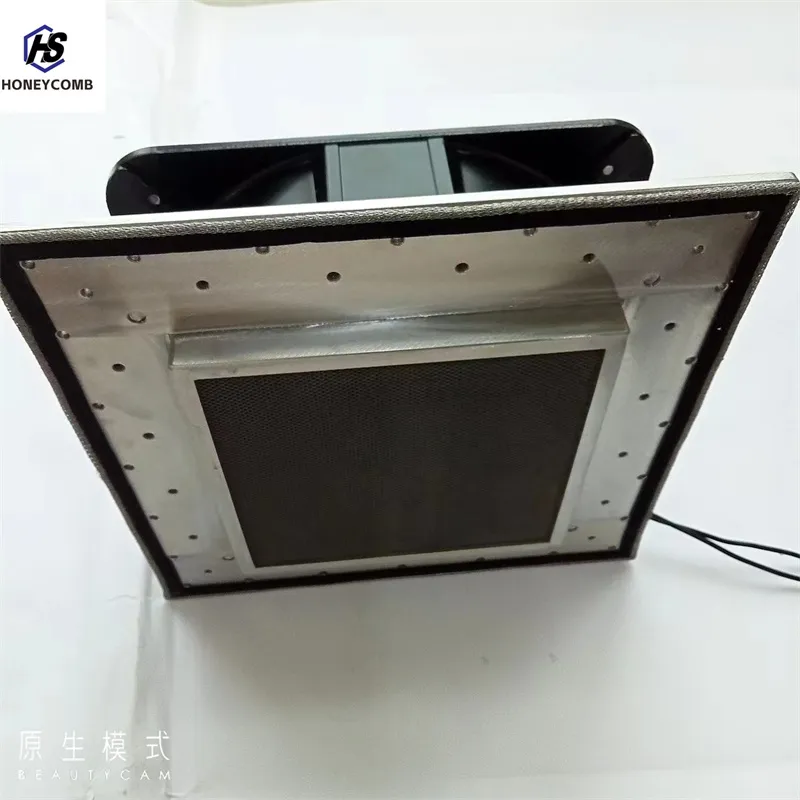

EMIEMC/RF Shielding Honeycomb Vent

Electromagnetic interference (EMI) is an ever-present challenge in the modern world, affecting the performance and reliability of electronic devices. As businesses innovate and develop increasingly sophisticated products, the need for effective EMI solutions becomes paramount. Among various solutions, EMI vents have emerged as a critical component in maintaining functionality and ensuring device integrity. This article delves into the practical applications, technical expertise, and authoritative insight into EMI vents, offering a trustworthy guide for integrating these solutions into your products.

Trustworthiness and Reliability Reliability is a key attribute when selecting EMI vents for your product. Poorly designed EMI solutions can result in device failure, leading to costly recalls and reputational damage. Working with manufacturers who provide detailed test reports and compliance certificates can ensure that the EMI vents meet the necessary performance standards. Additionally, trustworthy vendors often offer customization options and ongoing support, allowing products to be tailored specifically to client requirements and operational environments. This level of customer service demonstrates a commitment to quality and ensures that EMI vents perform effectively over the product's lifecycle. Real-world Experience and Applications EMI vents find applications across various industries including telecommunications, healthcare, defense, and automotive sectors. Consider a telecommunications company that integrates EMI vents in their server housing to maintain optimal airflow while ensuring reliable data transmission. By doing so, they significantly reduce the risk of data corruption caused by electromagnetic interference, providing a seamless user experience. In another instance, a healthcare device manufacturer implemented EMI vents in their medical imaging equipment. This choice not only maintained the equipment's performance by eliminating interference but also ensured patient safety and compliance with medical standards. Future Perspectives As technology evolves, the demand for superior EMI control solutions will continue to rise. Emerging trends such as IoT, 5G networks, and electronic vehicles will drive advancements in EMI vent technology. Future vents may incorporate smart materials and integrated sensors capable of dynamically adjusting to varying electromagnetic environments. In conclusion, EMI vents are indispensable in today's electronically-driven world. Through real-world applications and experience-led insights, the integration of expertly designed, authoritative, and trustworthy EMI vents ensures that electronic devices remain reliable and efficient. As we continue to innovate, the role of EMI vents in safeguarding against electromagnetic interference will become increasingly vital, making them a cornerstone of modern product development.

Trustworthiness and Reliability Reliability is a key attribute when selecting EMI vents for your product. Poorly designed EMI solutions can result in device failure, leading to costly recalls and reputational damage. Working with manufacturers who provide detailed test reports and compliance certificates can ensure that the EMI vents meet the necessary performance standards. Additionally, trustworthy vendors often offer customization options and ongoing support, allowing products to be tailored specifically to client requirements and operational environments. This level of customer service demonstrates a commitment to quality and ensures that EMI vents perform effectively over the product's lifecycle. Real-world Experience and Applications EMI vents find applications across various industries including telecommunications, healthcare, defense, and automotive sectors. Consider a telecommunications company that integrates EMI vents in their server housing to maintain optimal airflow while ensuring reliable data transmission. By doing so, they significantly reduce the risk of data corruption caused by electromagnetic interference, providing a seamless user experience. In another instance, a healthcare device manufacturer implemented EMI vents in their medical imaging equipment. This choice not only maintained the equipment's performance by eliminating interference but also ensured patient safety and compliance with medical standards. Future Perspectives As technology evolves, the demand for superior EMI control solutions will continue to rise. Emerging trends such as IoT, 5G networks, and electronic vehicles will drive advancements in EMI vent technology. Future vents may incorporate smart materials and integrated sensors capable of dynamically adjusting to varying electromagnetic environments. In conclusion, EMI vents are indispensable in today's electronically-driven world. Through real-world applications and experience-led insights, the integration of expertly designed, authoritative, and trustworthy EMI vents ensures that electronic devices remain reliable and efficient. As we continue to innovate, the role of EMI vents in safeguarding against electromagnetic interference will become increasingly vital, making them a cornerstone of modern product development.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025