- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 11, 2025 23:01

Back to list

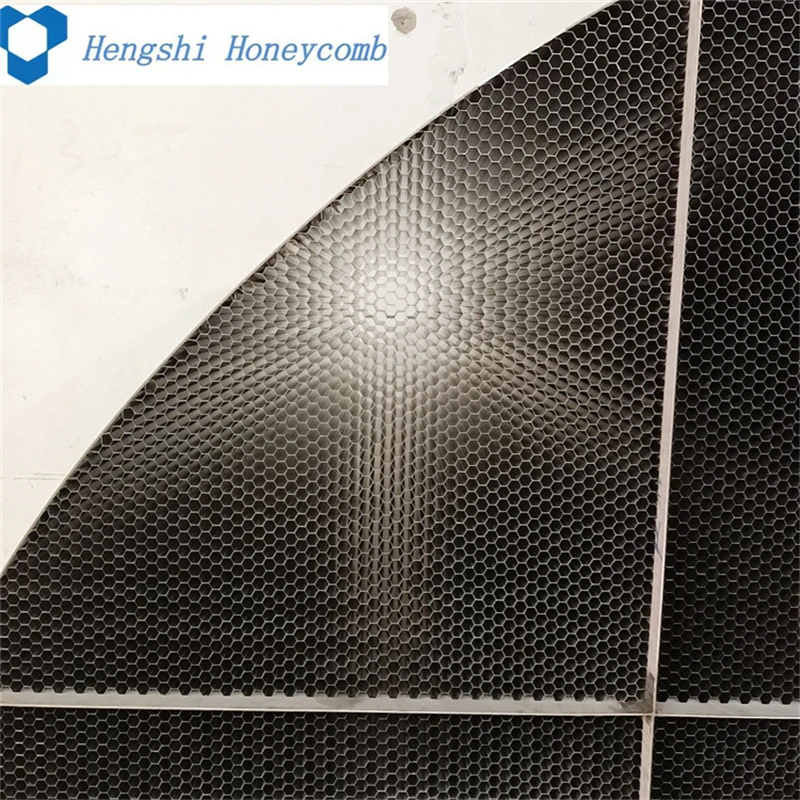

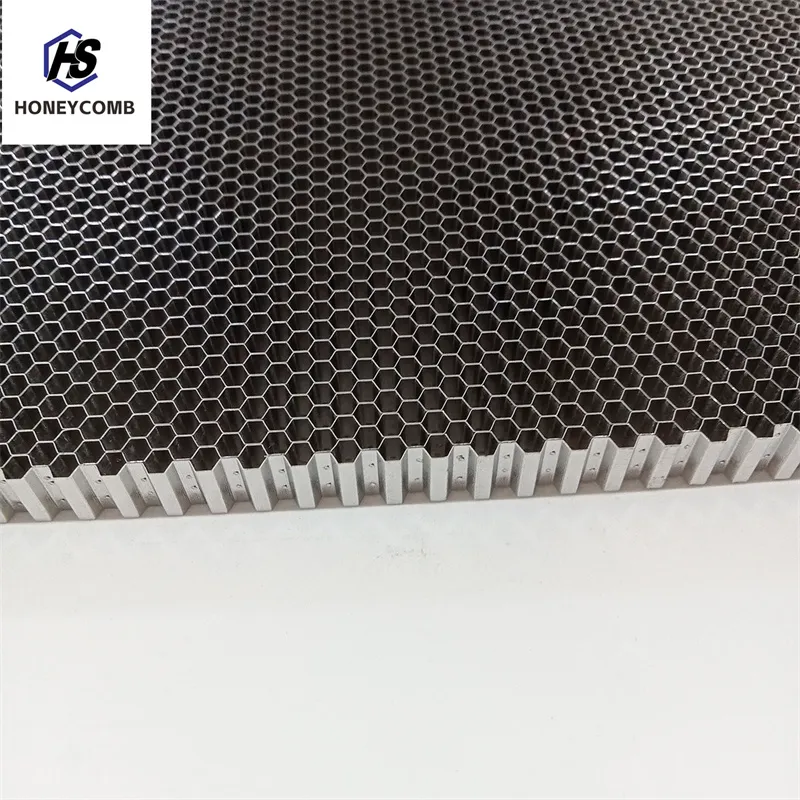

estructura de panal de aluminio

Aluminum honeycomb structures have emerged as a revolutionary component in modern engineering and architecture, seamlessly blending lightness with unparalleled durability. For industries ranging from aerospace to construction, these structures provide innovative solutions that speak to the core of engineering efficiency and design ingenuity.

As the demand for sustainable building materials grows, the environmental advantages of aluminum honeycomb structures become increasingly relevant. Aluminum is not only lightweight and durable but also highly recyclable, aligning with global sustainability goals. The energy required to produce aluminum is largely offset by the ability to recycle the material repeatedly without degradation in quality. This cyclical use of resources enhances the overall sustainability profile of projects using aluminum honeycomb structures. Trustworthiness in utilizing aluminum honeycomb structures is further bolstered by the extensive testing and regulatory compliance these materials undergo. Manufacturers adhere to rigorous international standards to ensure product reliability and safety. Certifications from recognized bodies provide assurance to engineers and architects that these materials can withstand the rigors of real-world application. From a product perspective, advancements in coating technology have expanded the potential applications of aluminum honeycomb structures. These coatings enhance resistance to environmental factors like corrosion and UV exposure, making them suitable for use in harsh climates and industries exposed to extreme conditions. Such innovations underline the adaptability and longevity of these structures, allowing them to meet the evolving needs of modern engineering challenges. In summation, the adoption of aluminum honeycomb structures within product manufacturing and construction offers compelling advantages across multiple dimensions. Their proven reliability, combined with cutting-edge manufacturing techniques and a commitment to sustainability, positions them as a beacon of modern engineering excellence. As industries continue to seek out materials that offer both performance and environmental responsibility, aluminum honeycomb structures stand out as a testament to human ingenuity meeting the call for a more sustainable future. Professionals venturing into projects that involve these panels can do so with confidence, knowing that they are supported by a robust foundation of experience, expertise, authority, and trustworthiness that these innovative solutions bring to the table.

As the demand for sustainable building materials grows, the environmental advantages of aluminum honeycomb structures become increasingly relevant. Aluminum is not only lightweight and durable but also highly recyclable, aligning with global sustainability goals. The energy required to produce aluminum is largely offset by the ability to recycle the material repeatedly without degradation in quality. This cyclical use of resources enhances the overall sustainability profile of projects using aluminum honeycomb structures. Trustworthiness in utilizing aluminum honeycomb structures is further bolstered by the extensive testing and regulatory compliance these materials undergo. Manufacturers adhere to rigorous international standards to ensure product reliability and safety. Certifications from recognized bodies provide assurance to engineers and architects that these materials can withstand the rigors of real-world application. From a product perspective, advancements in coating technology have expanded the potential applications of aluminum honeycomb structures. These coatings enhance resistance to environmental factors like corrosion and UV exposure, making them suitable for use in harsh climates and industries exposed to extreme conditions. Such innovations underline the adaptability and longevity of these structures, allowing them to meet the evolving needs of modern engineering challenges. In summation, the adoption of aluminum honeycomb structures within product manufacturing and construction offers compelling advantages across multiple dimensions. Their proven reliability, combined with cutting-edge manufacturing techniques and a commitment to sustainability, positions them as a beacon of modern engineering excellence. As industries continue to seek out materials that offer both performance and environmental responsibility, aluminum honeycomb structures stand out as a testament to human ingenuity meeting the call for a more sustainable future. Professionals venturing into projects that involve these panels can do so with confidence, knowing that they are supported by a robust foundation of experience, expertise, authority, and trustworthiness that these innovative solutions bring to the table.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025