- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 13, 2025 04:19

Back to list

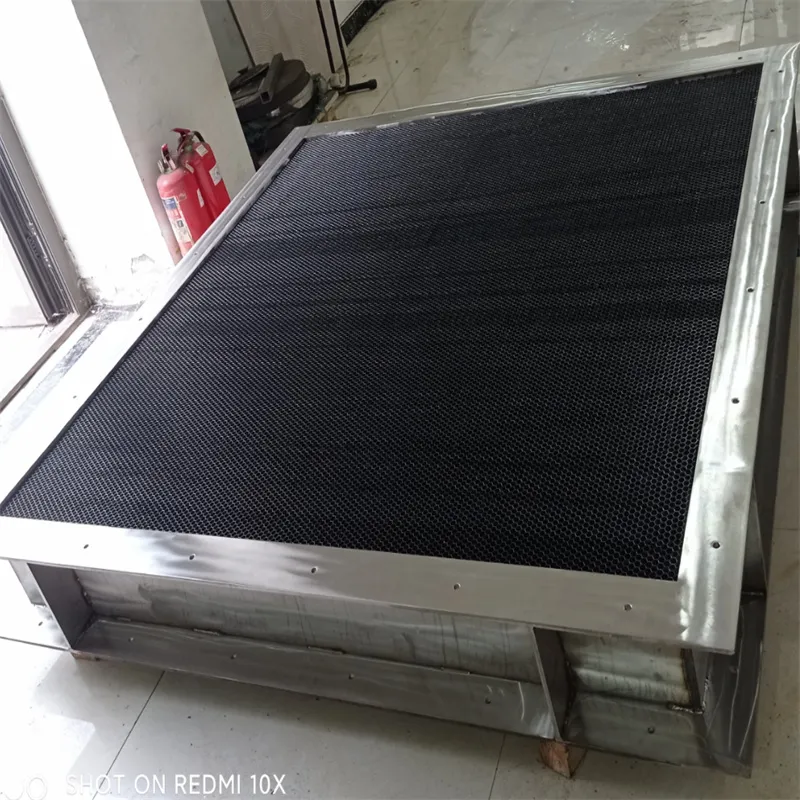

Stainless Steel Hengshi Honeycomb Core for Wind Tunnel Air Flow Straightener

Aluminum extruded honeycomb, a versatile and innovative product, has increasingly gained prominence in various industries. Its structural integrity and lightweight characteristics are just the beginning of what makes it a standout choice for numerous applications. This article delves into its unique advantages, applications, and why it has become a favored option among professionals.

In architecture, the aesthetic and functional versatility of aluminum honeycomb has sparked a revolution in design. Architects and designers find the material ideal for creating innovative structures that push the boundaries of form and function. Facades, internal partitions, and even furniture benefit from the sleek, modern look that aluminum honeycomb panels can provide. Furthermore, the material’s inherent fire resistance and sound insulation properties ensure it meets stringent safety and environmental regulations. Real-world experiences with extruded aluminum honeycomb also highlight its ease of installation and long-term durability. Builders and contractors appreciate the material’s compatibility with various construction methodologies, leading to reduced labor costs and faster project completion times. Its corrosion resistance further assures that structures maintain their integrity and appearance over time, reducing maintenance expenses. Trustworthiness in the supply chain of extruded aluminum honeycomb is crucial. Companies committed to quality control and regulation compliance ensure that their products meet international standards. Businesses that source their honeycomb from reputable manufacturers provide reassurance to their customers regarding the reliability and safety of their projects, a testament to the importance of authoritative sourcing and distribution. In summary, extruded aluminum honeycomb is more than just a lightweight material; it embodies innovation, efficiency, and sustainable development. Its myriad advantages make it indispensable for forward-thinking companies and professionals aiming to lead in their respective fields. By embracing this revolutionary material, industries not only enhance their current offerings but also catapult themselves into a future defined by cutting-edge technology and ecological responsibility.

In architecture, the aesthetic and functional versatility of aluminum honeycomb has sparked a revolution in design. Architects and designers find the material ideal for creating innovative structures that push the boundaries of form and function. Facades, internal partitions, and even furniture benefit from the sleek, modern look that aluminum honeycomb panels can provide. Furthermore, the material’s inherent fire resistance and sound insulation properties ensure it meets stringent safety and environmental regulations. Real-world experiences with extruded aluminum honeycomb also highlight its ease of installation and long-term durability. Builders and contractors appreciate the material’s compatibility with various construction methodologies, leading to reduced labor costs and faster project completion times. Its corrosion resistance further assures that structures maintain their integrity and appearance over time, reducing maintenance expenses. Trustworthiness in the supply chain of extruded aluminum honeycomb is crucial. Companies committed to quality control and regulation compliance ensure that their products meet international standards. Businesses that source their honeycomb from reputable manufacturers provide reassurance to their customers regarding the reliability and safety of their projects, a testament to the importance of authoritative sourcing and distribution. In summary, extruded aluminum honeycomb is more than just a lightweight material; it embodies innovation, efficiency, and sustainable development. Its myriad advantages make it indispensable for forward-thinking companies and professionals aiming to lead in their respective fields. By embracing this revolutionary material, industries not only enhance their current offerings but also catapult themselves into a future defined by cutting-edge technology and ecological responsibility.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025