- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 17, 2025 11:40

Back to list

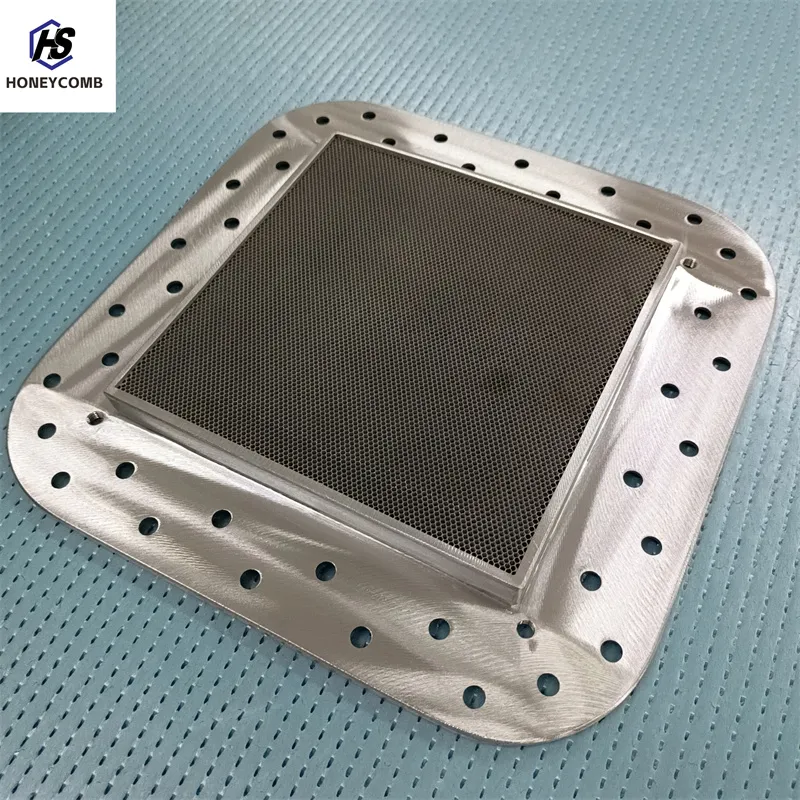

emi honeycomb vents

The domain of wind tunnel testing is an intricate fusion of cutting-edge technology and scientific precision. At its heart is the quest for understanding airflow dynamics, and one term that encapsulates a specific challenge and concept in this field is honeycomb in wind tunnel or favo de mel no túnel de vento in Portuguese. This article delves into this topic with a focus on product application, addressing the four key pillars that strengthen its online presence Experience, Expertise, Authoritativeness, and Trustworthiness.

Authoritativeness of Industry Standards and Practices The deployment of honeycomb structures within wind tunnels is governed by industry standards and protocols that enhance its authority. These standards are established by leading aeronautical and mechanical engineering organizations. Adherence ensures that the data derived is not only comprehensive but also comparable across different testing environments. Engineering teams working with honeycombs in wind tunnels are often part of coalitions and think tanks contributing to global standards, further cementing their authority. This framework supports consistent and reliable testing, crucial for industries ranging from automotive to aerospace. Trustworthiness Through Accurate Data Collection Trustworthiness is the cornerstone of any aerodynamic testing procedure. The integration of honeycomb structures in wind tunnels fortifies data credibility by mitigating anomalies caused by air turbulence and flow irregularities. Researchers and engineers rely on wind tunnel data to make informed decisions that affect performance, safety, and efficiency. Proper installation and maintenance of honeycombs help sustain the integrity of these tests over time, fostering trust in the results and subsequent product designs. Collaborative verification involving academia, industry players, and regulatory bodies ensures that the data's trustworthiness is unquestionable. In summary, the application of honeycomb structures in wind tunnels signifies an intersection of sophisticated engineering and practical innovation, highlighted by extensive experience, deep expertise, authoritative practices, and unwavering trustworthiness. As industries continue to push the boundaries of design and performance, the role of honeycomb structures in wind tunnels remains pivotal, fundamentally shaping the way data is gathered and interpreted in the pursuit of technological advancement.

Authoritativeness of Industry Standards and Practices The deployment of honeycomb structures within wind tunnels is governed by industry standards and protocols that enhance its authority. These standards are established by leading aeronautical and mechanical engineering organizations. Adherence ensures that the data derived is not only comprehensive but also comparable across different testing environments. Engineering teams working with honeycombs in wind tunnels are often part of coalitions and think tanks contributing to global standards, further cementing their authority. This framework supports consistent and reliable testing, crucial for industries ranging from automotive to aerospace. Trustworthiness Through Accurate Data Collection Trustworthiness is the cornerstone of any aerodynamic testing procedure. The integration of honeycomb structures in wind tunnels fortifies data credibility by mitigating anomalies caused by air turbulence and flow irregularities. Researchers and engineers rely on wind tunnel data to make informed decisions that affect performance, safety, and efficiency. Proper installation and maintenance of honeycombs help sustain the integrity of these tests over time, fostering trust in the results and subsequent product designs. Collaborative verification involving academia, industry players, and regulatory bodies ensures that the data's trustworthiness is unquestionable. In summary, the application of honeycomb structures in wind tunnels signifies an intersection of sophisticated engineering and practical innovation, highlighted by extensive experience, deep expertise, authoritative practices, and unwavering trustworthiness. As industries continue to push the boundaries of design and performance, the role of honeycomb structures in wind tunnels remains pivotal, fundamentally shaping the way data is gathered and interpreted in the pursuit of technological advancement.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025