- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 00:54

Back to list

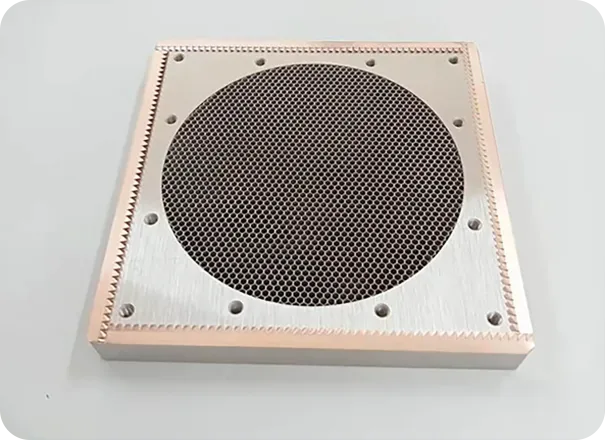

filtres en nid d'abeille emi

In the landscape of electromagnetic interference (EMI) shielding, the innovative honeycomb filter has emerged as a game-changer. Drawing from real-world experience and extensive expertise, honeycomb EMI filters are increasingly recognized for their efficiency and reliability. To appreciate the full potential of these fascinating designs, it’s crucial to delve into their unique characteristics and applications.

Practical experience with honeycomb EMI filters highlights their versatility. In the telecommunications industry, where signal clarity is paramount, these filters prove indispensable. They help prevent cross-talk and maintain signal integrity, which is essential for reliable communication. Likewise, in the aerospace sector, where systems must withstand a barrage of electronic noise while meeting stringent regulatory standards, honeycomb filters can offer an unparalleled shielding solution. Moreover, these filters are often incorporated into the design of medical devices, which rely on precision and reliability to deliver patient care. The ability of honeycomb structures to provide maximum surface coverage while maintaining airflow is particularly beneficial in maintaining device temperatures within operational ranges, ensuring both performance and safety in medical settings. Extensive research continues to push the boundaries of honeycomb filter technology. As new materials emerge and manufacturing technologies evolve, the potential applications and efficiency of these filters are expected to expand further. For instance, 3D printing technologies might enable even more complex designs, achieving even greater precision in filtering capacity while reducing manufacturing costs. In summary, honeycomb EMI filters exemplify a synthesis of natural inspiration and advanced engineering. Their capacity to protect sensitive electronic environments from the disruptive forces of electromagnetic interference is unrivaled by traditional methods. The combination of thorough design, adherence to exacting standards, and proven field performance renders these filters not just reliable but essential components in a host of critical applications. As the electromagnetic landscape continues to grow in complexity, the demand for effective solutions like honeycomb EMI filters will undoubtedly rise. Their role in safeguarding technology, ensuring safety, and maintaining operational integrity across industries will become ever more pivotal. With the continued commitment to innovation and quality, honeycomb EMI filters will remain at the forefront of EMI shielding technology, offering a testament to the enduring relationship between nature’s ingenuity and human innovation.

Practical experience with honeycomb EMI filters highlights their versatility. In the telecommunications industry, where signal clarity is paramount, these filters prove indispensable. They help prevent cross-talk and maintain signal integrity, which is essential for reliable communication. Likewise, in the aerospace sector, where systems must withstand a barrage of electronic noise while meeting stringent regulatory standards, honeycomb filters can offer an unparalleled shielding solution. Moreover, these filters are often incorporated into the design of medical devices, which rely on precision and reliability to deliver patient care. The ability of honeycomb structures to provide maximum surface coverage while maintaining airflow is particularly beneficial in maintaining device temperatures within operational ranges, ensuring both performance and safety in medical settings. Extensive research continues to push the boundaries of honeycomb filter technology. As new materials emerge and manufacturing technologies evolve, the potential applications and efficiency of these filters are expected to expand further. For instance, 3D printing technologies might enable even more complex designs, achieving even greater precision in filtering capacity while reducing manufacturing costs. In summary, honeycomb EMI filters exemplify a synthesis of natural inspiration and advanced engineering. Their capacity to protect sensitive electronic environments from the disruptive forces of electromagnetic interference is unrivaled by traditional methods. The combination of thorough design, adherence to exacting standards, and proven field performance renders these filters not just reliable but essential components in a host of critical applications. As the electromagnetic landscape continues to grow in complexity, the demand for effective solutions like honeycomb EMI filters will undoubtedly rise. Their role in safeguarding technology, ensuring safety, and maintaining operational integrity across industries will become ever more pivotal. With the continued commitment to innovation and quality, honeycomb EMI filters will remain at the forefront of EMI shielding technology, offering a testament to the enduring relationship between nature’s ingenuity and human innovation.

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025